How to make ice silk composite mat

A production method and technology of ice silk, which can be applied to household appliances, bedspreads, applications, etc., can solve the problems of destroying natural resources, affecting comfort, and shortage of natural resources, and achieving the effects of good hand feel, improved coolness, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

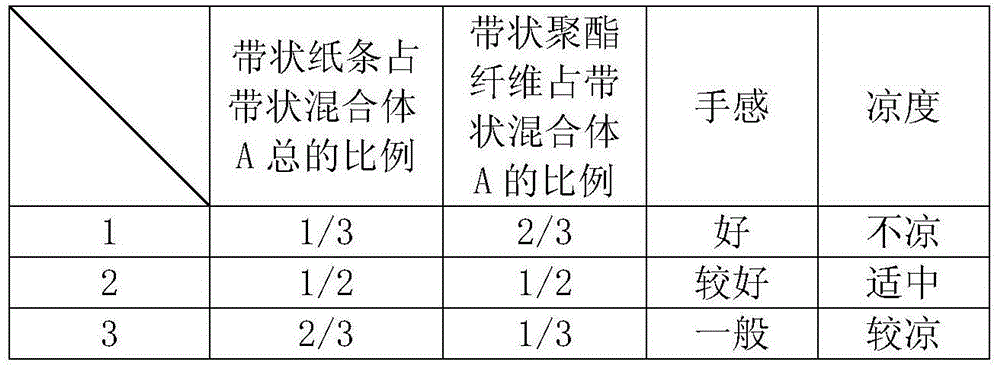

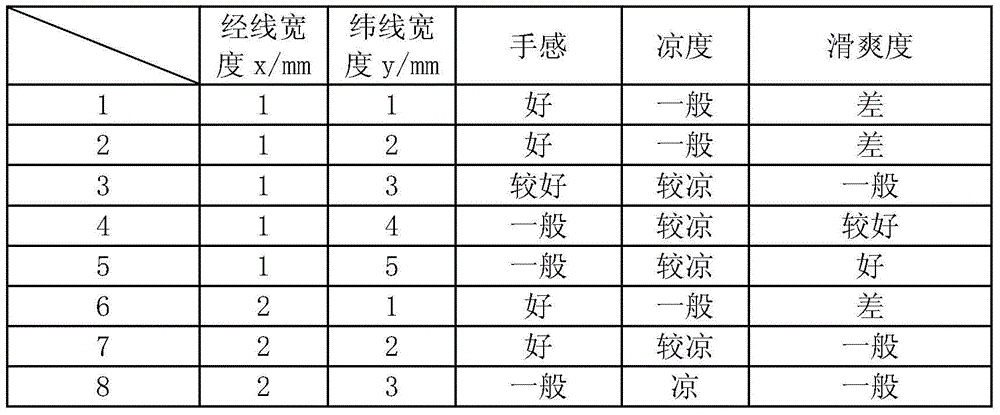

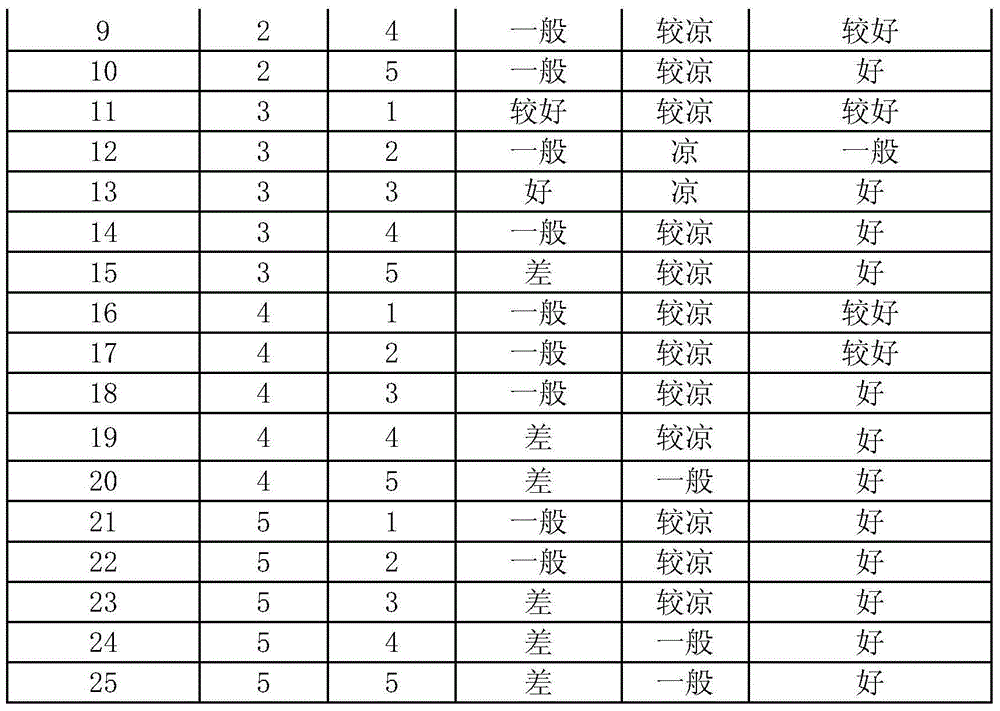

Embodiment 1

[0051] A method for making ice silk composite mat, characterized in that the method comprises the following steps:

[0052] 1). After the waste paper raw materials are decontaminated by a high-energy hydraulic pulper, they are screened and removed;

[0053] 2). The pulp in step 1) is made into semi-finished paper sheets through a paper processing technology and subjected to mildew-proof, water-proof and sterilization treatments;

[0054] 3). Fold the semi-finished paper sheet after the anti-mold, waterproof, and sterilization treatment in step 2) into a strip of paper with the required thickness and width;

[0055] 4) Put the polyester raw materials in a drying box for drying;

[0056] 5) Put the polyester raw material dried in step 4) into the melting box to melt, and stir through the stirring rod;

[0057] 6) Put the polyester raw material melted in step 5) into the spinning box, and draw the yarn through the spinning box to form polyester fiber filaments, and then cool;

[0058] 7) Put...

Embodiment 2

[0082] A method for making ice silk composite mat, characterized in that the method comprises the following steps:

[0083] 1). After the waste paper raw materials are degraded by a high-energy hydraulic pulper, they are screened and slag removed;

[0084] 2). The pulp in step 1) is made into semi-finished paper sheets through a paper processing technology and subjected to mildew-proof, waterproof and sterilization treatments;

[0085] 3). Fold the semi-finished paper sheet after the anti-mold, waterproof, and sterilization treatment in step 2) into a strip of paper with the required thickness and width;

[0086] 4) Put the polyester raw materials in a drying box for drying;

[0087] 5) Put the polyester raw material dried in step 4) into the melting box to melt, and stir through the stirring rod;

[0088] 6) Put the polyester raw material melted in step 5) into the spinning box, and draw the yarn through the spinning box to form polyester fiber filaments, and then cool;

[0089] 7) Put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com