Humerus greater tuberosity locking plate

A large tubercle and steel plate technology, applied in the direction of outer plate, fixer, internal bone synthesis, etc., can solve the problems affecting patients' early functional rehabilitation exercise, high tension band steel wire fixation strength, and reduce the stability between fracture fragments, etc., to achieve fixation Good stability, low cost, improved safety and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

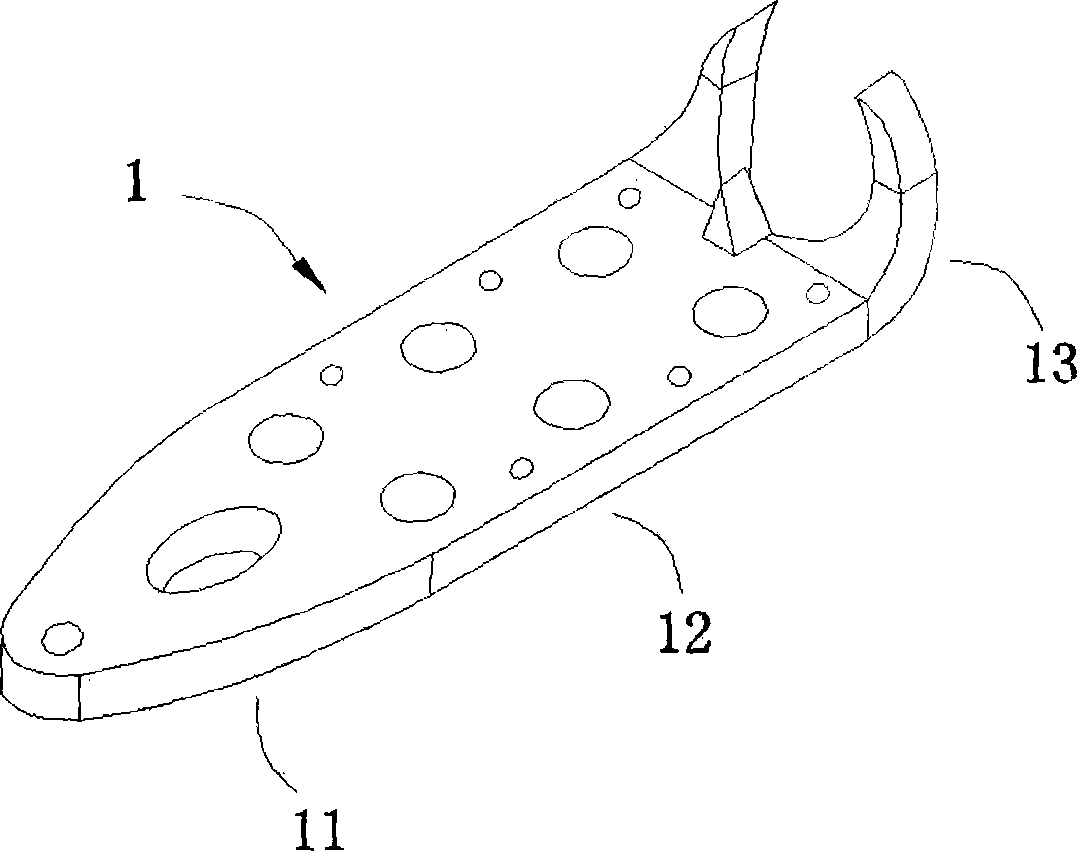

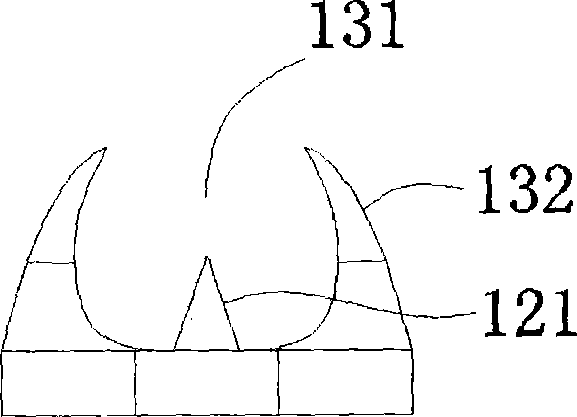

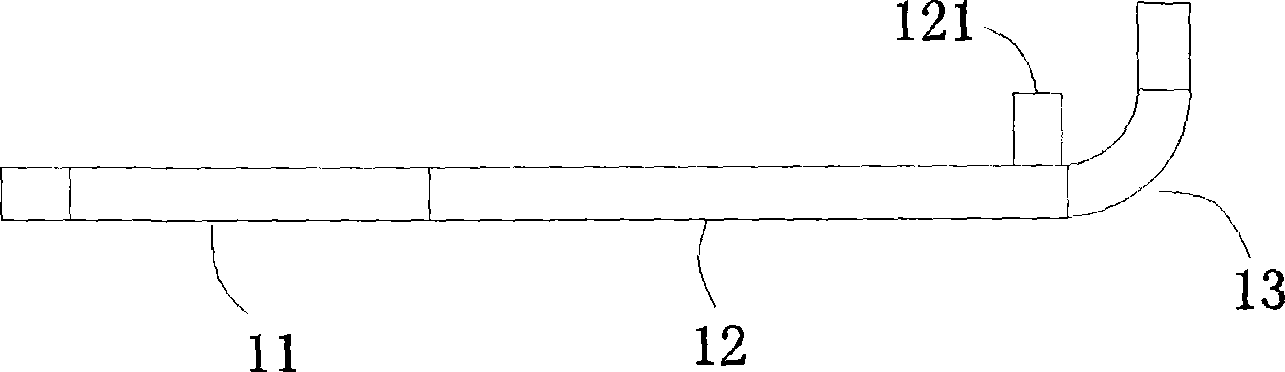

[0019] see Figure 1 to Figure 4 , a locking plate for the greater tuberosity of humerus provided in this embodiment, which includes a plate body 1, one end of the plate body 1 is tapered to form a fixed tail portion 11, the middle portion extends horizontally to form a fixed middle portion 12, and the other end faces to one side direction bending to form a fixed head 13, the middle part of the fixed head 13 is provided with a gap 131, so that a claw 132 is formed symmetrically on both sides, and the middle of the connection between the fixed middle part 12 and the fixed head 13 The position is provided with a protrusion 121, the fixed middle part 12 is provided with a plurality of locking screw holes 122 and Kirschner wire temporary fixing holes 123, and the fixed tail 11 is provided with a distal adjustment hole 111 and a distal Kirschner wire temporary Fixing hole 112 .

[0020] better, see figure 2 , the lower end of the claw 132 is relatively large, the upper end is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com