Vibration type self-cleaning method and device for air filter screen

An air filter and vibration device technology, applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of time-consuming and laborious, air pollution, air filter blockage, etc., to reduce the use cost and labor intensity. , good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

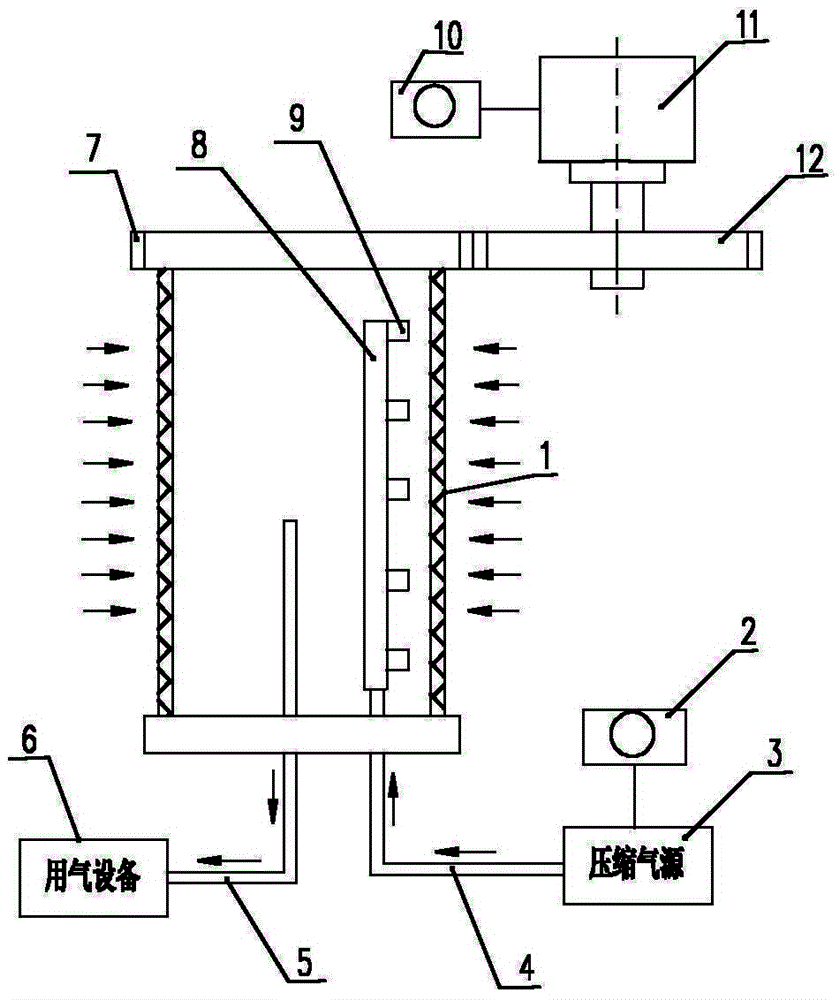

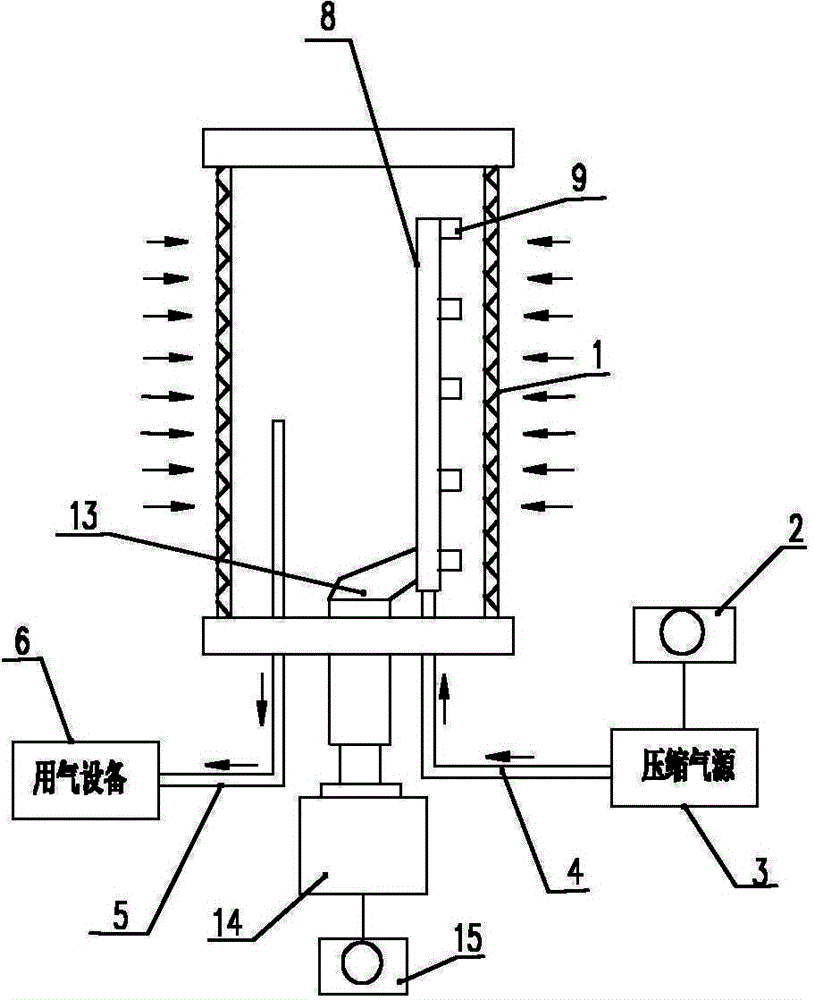

[0018] Such as figure 1 As shown, the mixed natural air is filtered through the air filter 1 to remove particulate dirt such as dust and impurities, and then enters the filtered and purified side of the air filter 1 for use. Part of the dust or particulate dirt may adhere to the air filter 1, the air device 6 is connected to the suction pipe 5, and the suction end of the suction pipe 5 is inserted into the side of the air filter 1 after air filtration and purification, and the filtered and purified air is inhaled, usually in the suction pipe. The suction end of 5 is provided with mesh suction holes to increase the suction area and secondary filtration.

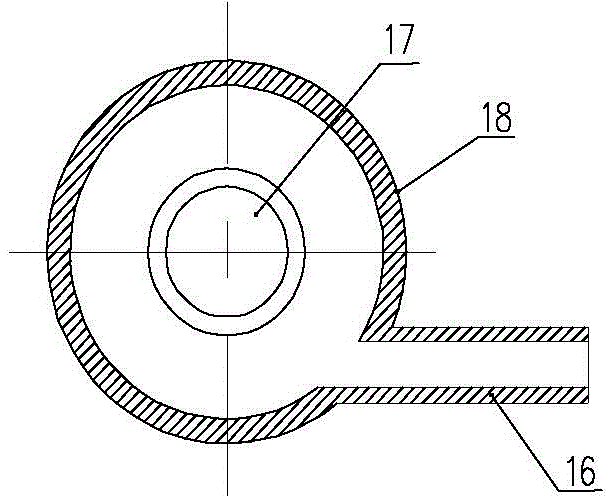

[0019] A kind of air filter screen vibration self-cleaning method of the present invention, at first, will arrange a gas vibrating device on one side of air filter screen 1, the ultrasonic gas that gas vibration device produces acts on the air filter screen 1, on the air filter screen Ultrasonic vibration is generated locally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com