A side-mounted compression garbage truck

A garbage truck and compression type technology, which is applied in the field of side-mounted compression garbage trucks, can solve the problems of complex structure, single shape of guide rail, trash can falling off, etc., and achieve the effects of improving transportation efficiency, high compression efficiency and high degree of versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the accompanying drawings. For the convenience of description, the forward direction of the garbage truck is defined as the front end.

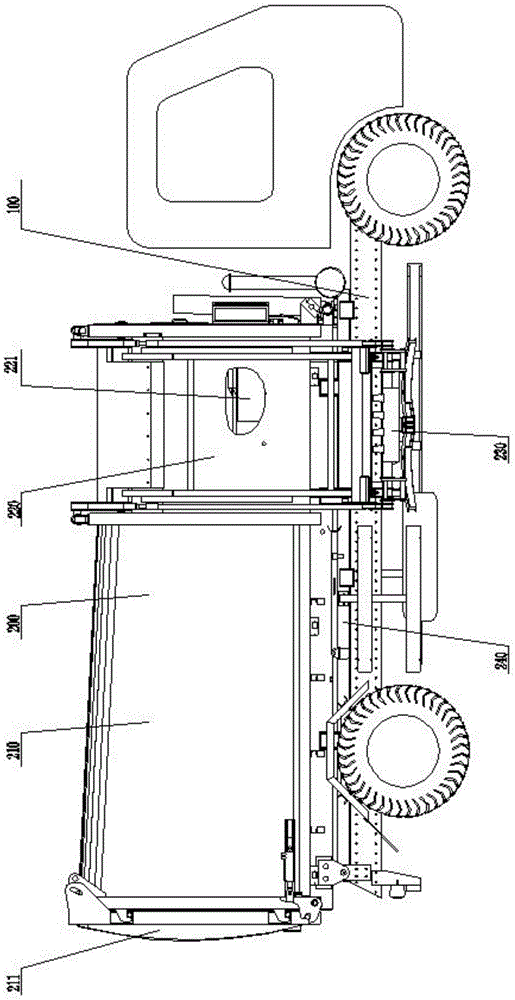

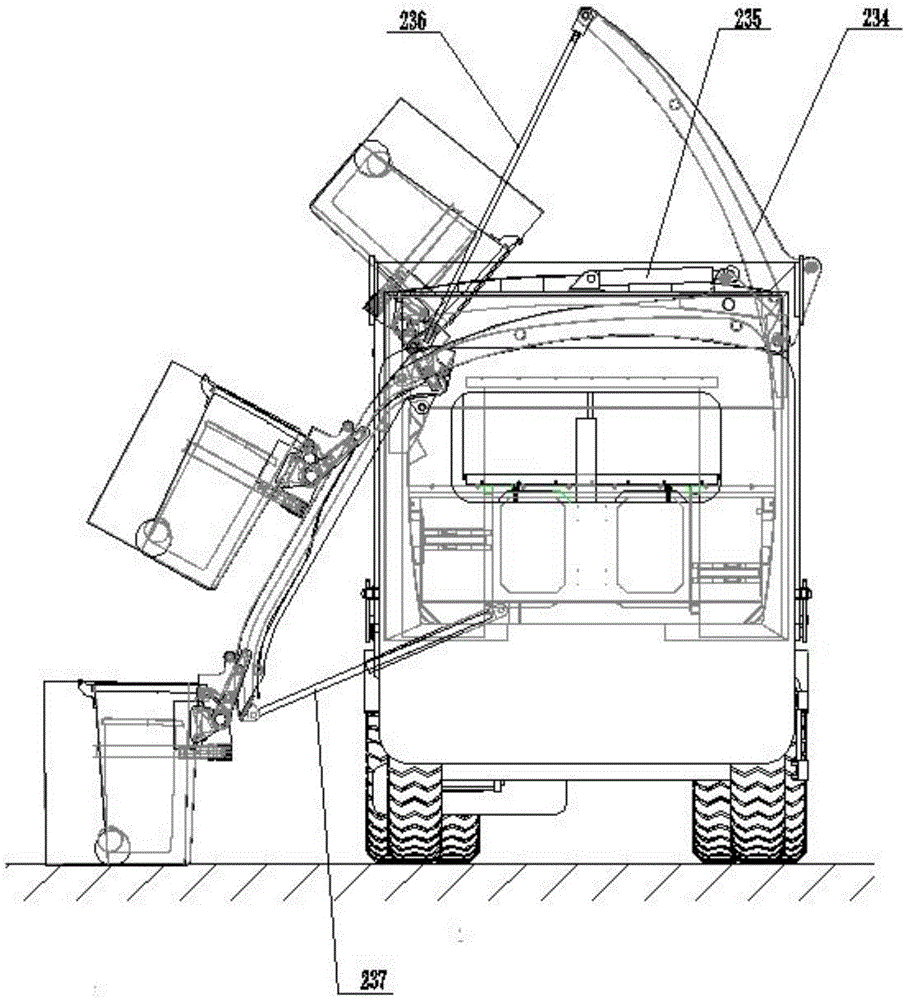

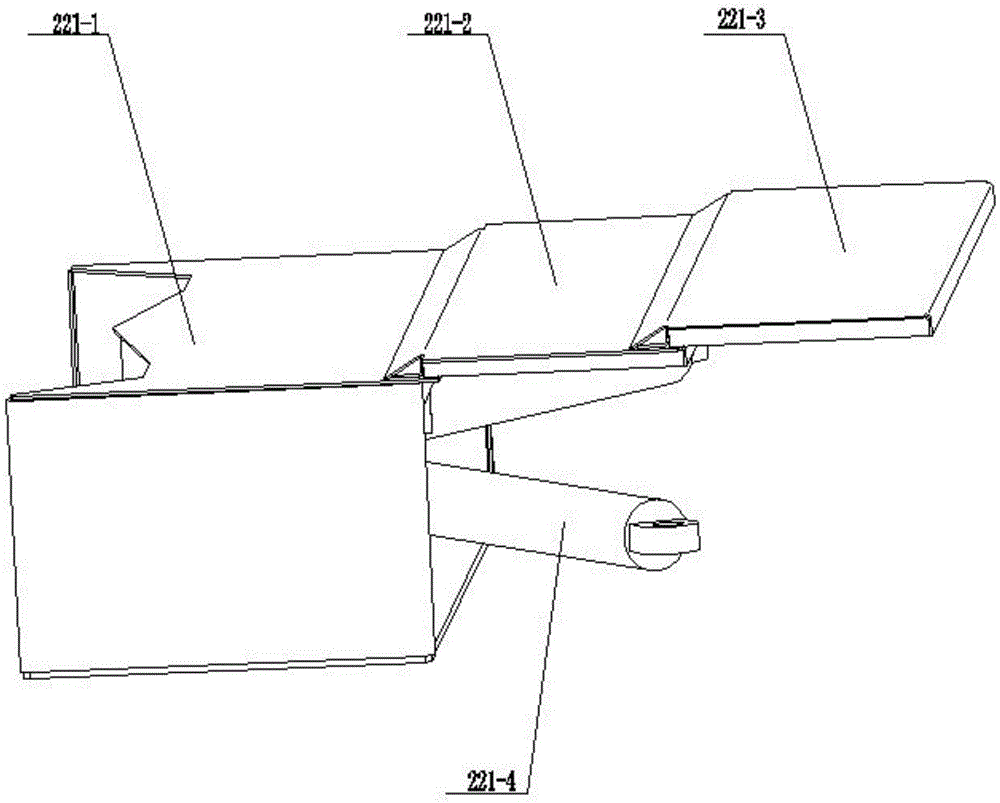

[0043] like figure 1 As shown, a side-mounted compression garbage truck includes a chassis 100 and an upper body 200. The upper body includes a box body 210, a stuffing box 220, a collecting device 230 and a self-unloading device 240, and the box body 210 and the stuffing box 220 are installed On the upper side of the vehicle chassis 100, the stuffing box 220 is connected to the front end of the box body 210, the self-unloading device 240 is installed between the chassis 100 and the box body 210, and the collecting device 230 is arranged on the side of the stuffing box 220, inside the stuffing box 220 It also has a compression device 221, and the box body 210 also has a rear door 211 that can be rotated and opened. The collection device 230 includes a guide rail as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com