Rectangular fish plate structure of tower crane

A technology of tower cranes and fishplates, which is applied to cranes and other directions, can solve the problems of not meeting the requirements of large and medium-sized tower cranes, consuming a lot of manpower and material resources, and inconvenient installation, so as to achieve simple and practical design, improve efficiency, Ease of installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

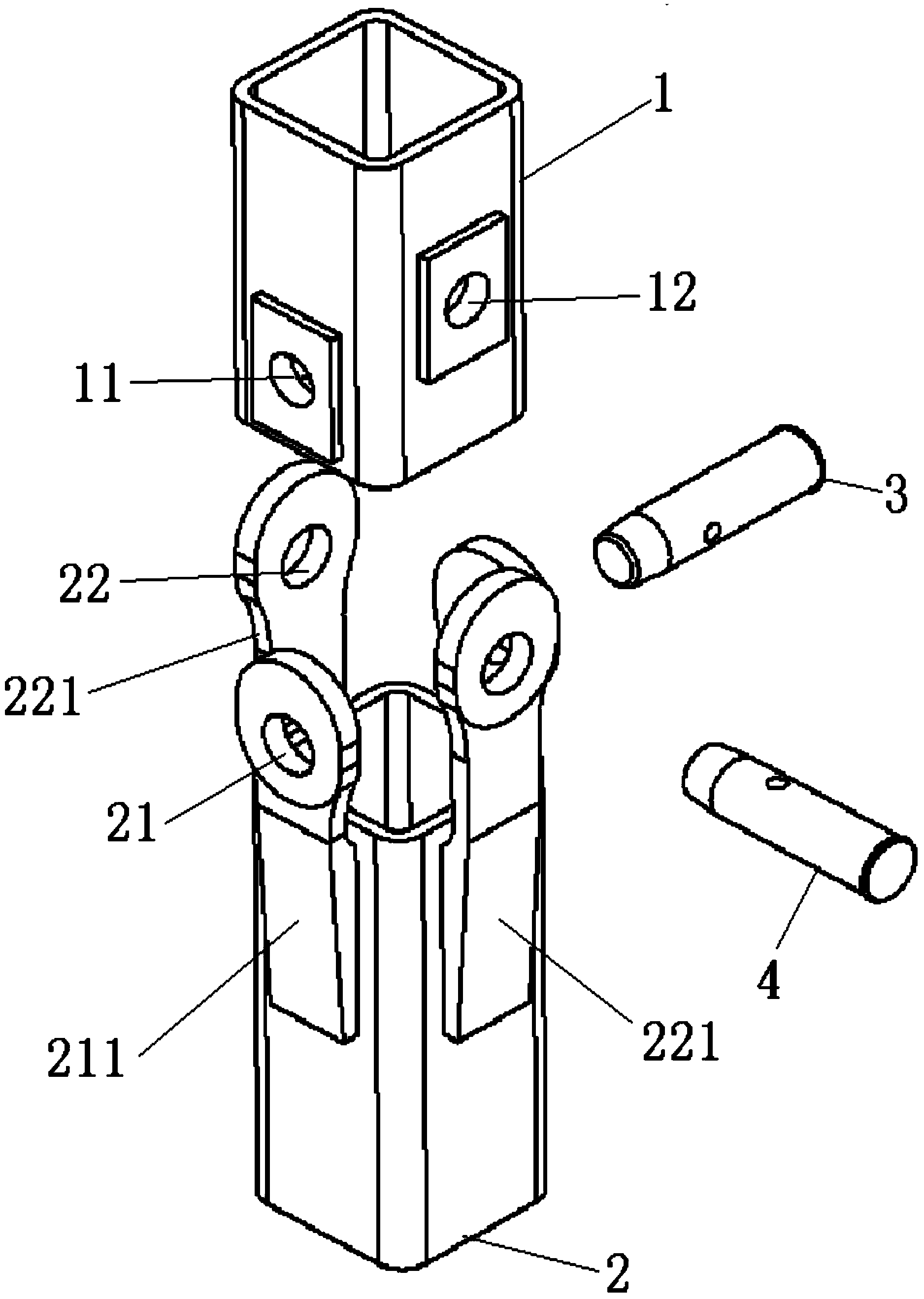

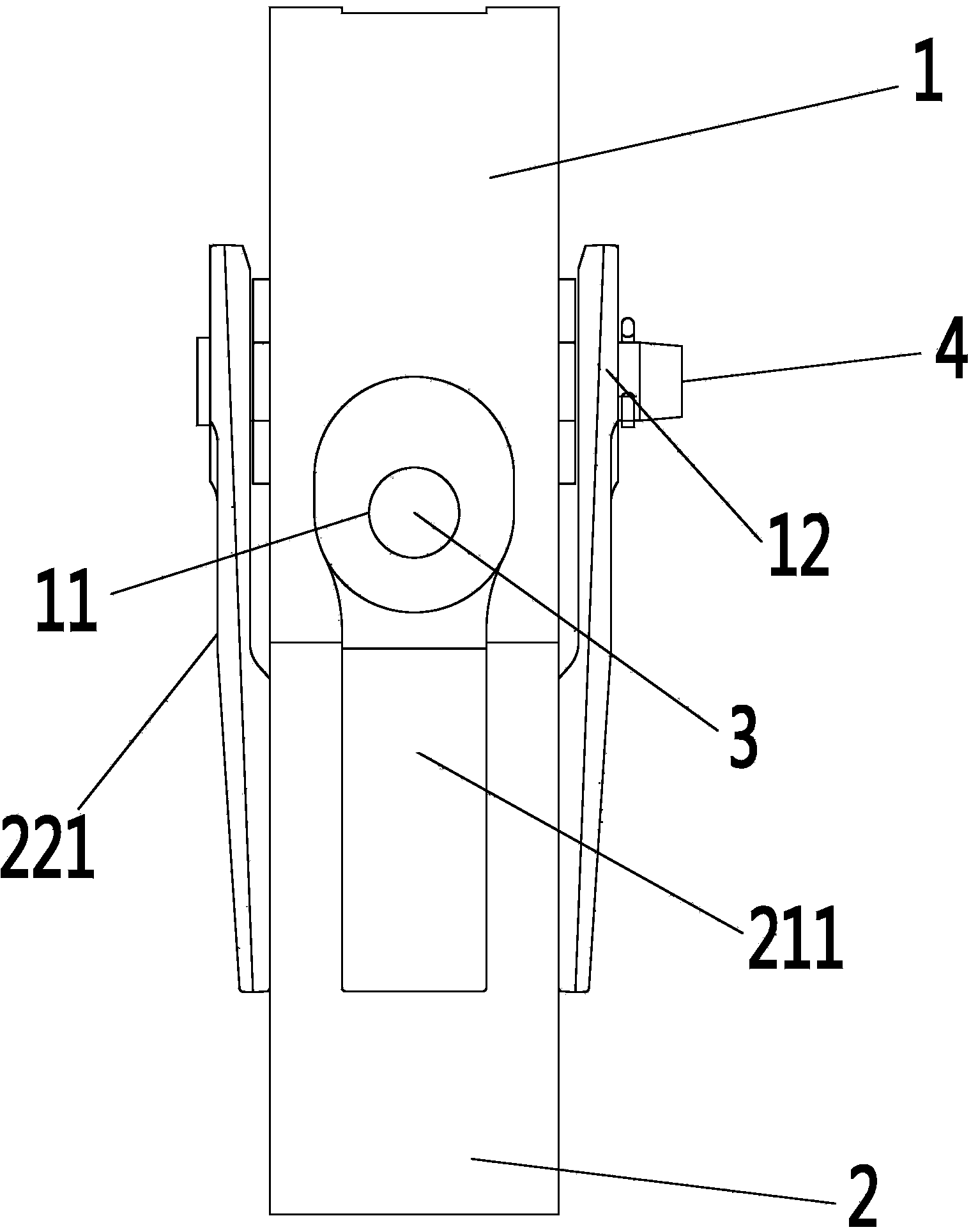

[0018] Such as figure 1 , figure 2 The tower crane rectangular fishplate structure shown includes an upper rectangular tube 1, a lower rectangular tube 2, a long fishplate pin 4 and a short fishplate pin 3, and the two opposite tube walls of the upper rectangular tube 1 Long fishplate positioning holes 12 are provided on the top, and short fishplate positioning holes 11 are provided on the other two opposite tube walls of the upper rectangular tube 1;

[0019] Two opposite tube walls of the lower rectangular tube 2 are provided with long fish plate 221, and the long fish plate 221 is provided with a long fish plate through hole 22, and the other two opposite tube walls of the lower rectangular tube 2 Both are provided with short fishplates 211, and the short fishplates 211 are provided with short fishplate through holes 21;

[0020] The long fishplate pin 4 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com