Inner diameter gauge

A technology of checking tool and inner diameter, applied in the field of production and verification of ring-shaped products, can solve problems ranging from hundreds of thousands of yuan to several million yuan or even tens of millions of yuan. Trouble and other problems, to achieve the effect of convenient operation, fast detection speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

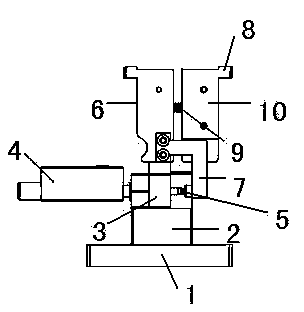

[0015] Such as figure 1 An embodiment of the inner diameter inspection tool of the present invention is shown, the inner diameter inspection tool includes a base 1, a base 2 is provided on the base 1, a splint 3 is arranged on the base 2, and thousands of splints are arranged on both sides of the splint 3. Divide the meter 4 and the meter head 5, the splint 3 is provided with a measuring mechanism 6, the measuring mechanism 6 is equipped with a connecting piece 7, the connecting piece 7 is in contact with the meter head 5, the upper part of the measuring mechanism 6 is provided with an arc-shaped measuring head 8, the measuring mechanism 6 is provided with a spring 9 inside, the measuring mechanism 6 is composed of two measuring pieces 10, the two measuring pieces 10 are connected by the spring 9, the connecting piece 7 is connected to one of the measuring pieces 10 in the measuring mechanism 6, and is not connected to the other touch. The internal diameter inspection tool h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com