Light tracking based oil shale pyrolysis gas detection device and method

A detection method, a technology of pyrolysis gas, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as inability to measure synchronously, and achieve the effect of simple optical path design, maintenance of measurement accuracy, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

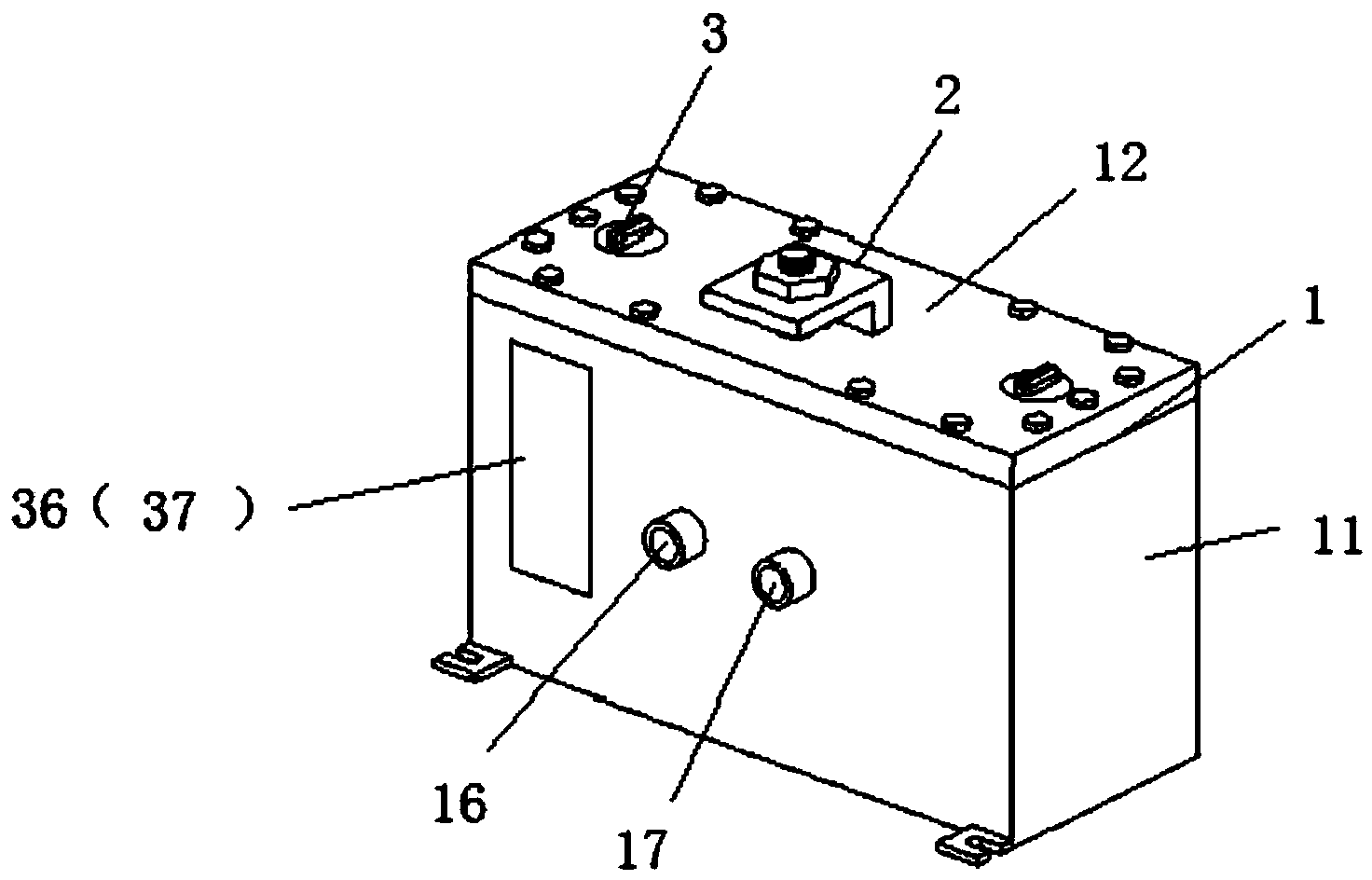

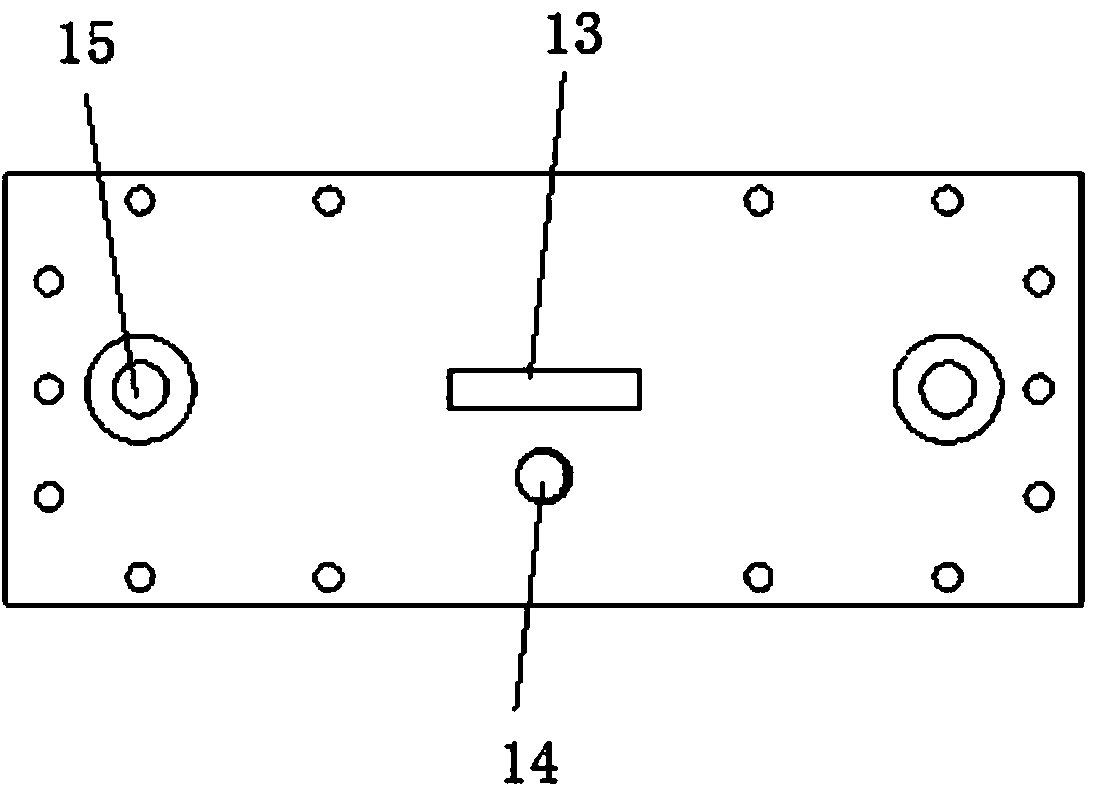

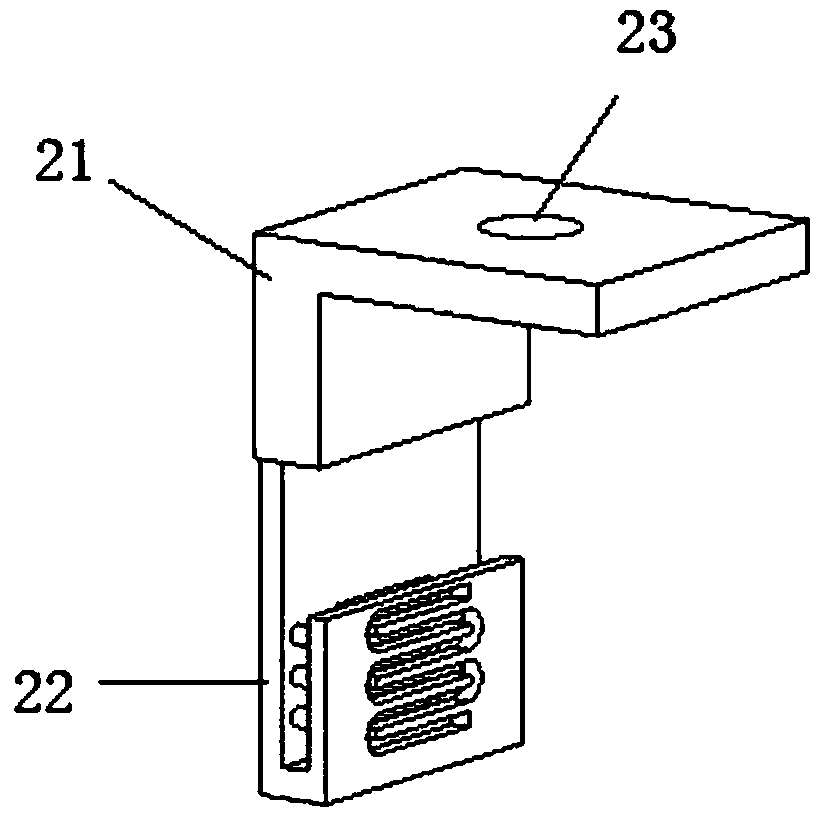

[0029] In order to have a clearer understanding of the technical scheme, purpose and effect of the present invention, descriptions are now given with reference to the accompanying drawings.

[0030] The purpose of the invention is to provide matching gas detection for a terahertz time-domain spectrometer, and can use the terahertz spectroscopic technology to track the gas produced by the pyrolysis reaction of oil shale. Its basic idea is to design a terahertz optical path in a pyrolysis environment with set temperature and pressure conditions, so that the terahertz wave is transmitted through the pyrolysis gas, and then received by the spectrometer. According to the pyrolysis environment conditions, use Spectral changes characteristically measure the characteristics of pyrolysis reactants. The form of the optical path is to let the terahertz wave pass through the gas from the positive and negative directions at two different times in the space of the gas reactant during one me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com