Defect prediction method and device

A prediction method and a technology of a prediction device, which are applied in the field of data processing and can solve problems such as failure to predict defects, overfitting or underfitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

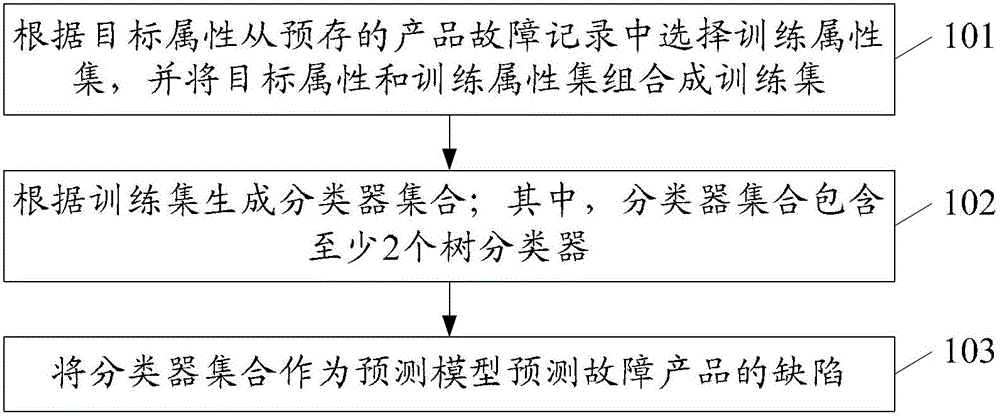

[0089] An embodiment of the present invention provides a defect prediction method, such as figure 1 As shown, the method may include:

[0090] 101. Select a training attribute set from prestored product fault records according to the target attribute, and combine the target attribute and the training attribute set into a training set.

[0091] Among them, when a product fails, the fault detection personnel generally hope to quickly locate the defect type of the faulty product or the device that causes the product to fail, so as to save the maintenance time of the maintenance personnel, and to realize the fault detection The defect type of the product or the device that causes the product to be faulty can be quickly located by training the prediction model in advance. First, the fault detection personnel can collect the information of the product that has failed in the production process or in the process of use, and these The information is recorded in the product failure rec...

Embodiment 2

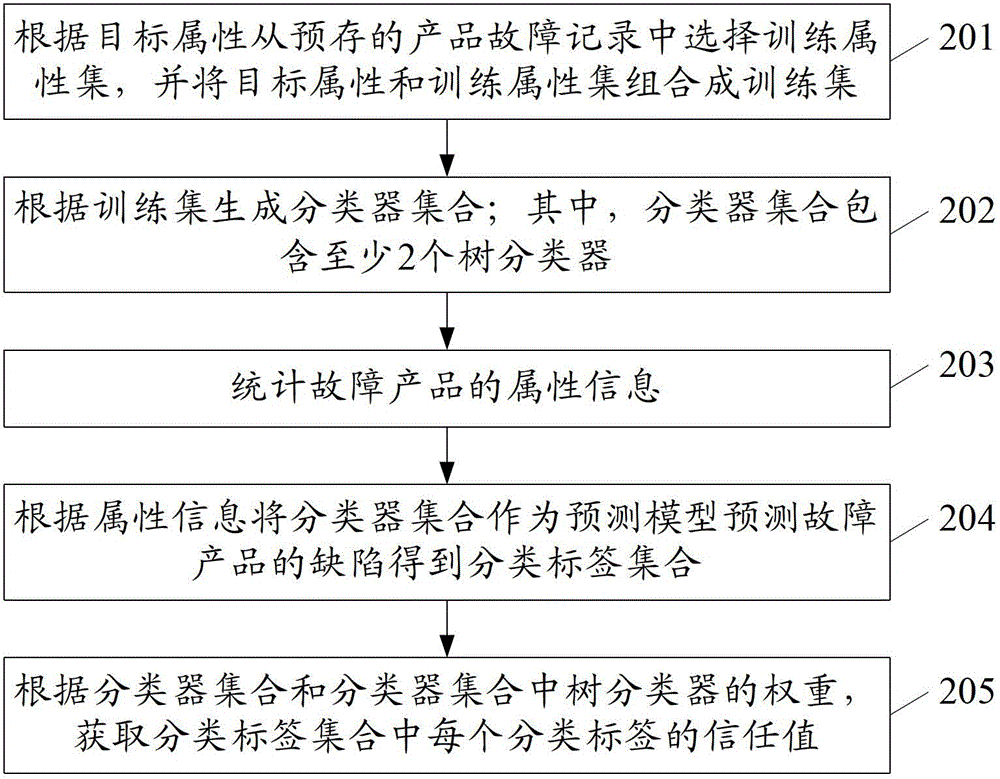

[0098] An embodiment of the present invention provides a defect prediction method, such as figure 2 As shown, the method may include:

[0099] 201. Select a training attribute set from prestored product fault records according to the target attribute, and combine the target attribute and the training attribute set into a training set.

[0100]Specifically, when a product fails during production or use, generally fault detection personnel hope to quickly locate the defect type of the faulty product or the faulty device, and for any product, The occurrence of faults or defects is related to the objective information of the product, such as the model of the product, the environment in which it is used, the source of raw materials, and so on. In order to quickly locate the defect type of the faulty product or the faulty device when the product has a fault or defect, it is possible to select from the product fault records of products that have failed during production or use. At...

Embodiment 3

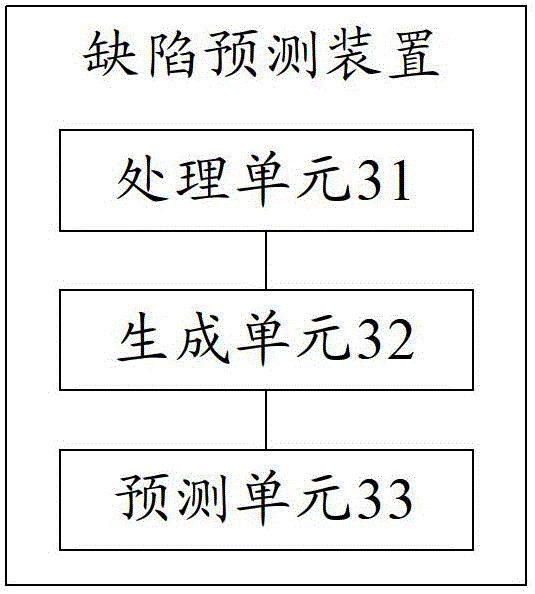

[0139] An embodiment of the present invention provides a defect prediction device, such as image 3 As shown, it includes: a processing unit 31 , a generating unit 32 , and a predicting unit 33 .

[0140] The processing unit 31 is configured to select a training attribute set from pre-stored product failure records according to the target attribute, and combine the target attribute and the training attribute set into a training set; wherein the target attribute is a defect of a historical faulty product Attributes.

[0141] The generating unit 32 is configured to generate a classifier set according to the training set obtained by the processing unit 31; wherein, the classifier set includes at least two tree classifiers.

[0142] The prediction unit 33 is configured to use the set of classifiers generated by the generation unit 32 as a prediction model to predict defects of faulty products.

[0143] Further, the training set includes M training units, and each training unit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com