Micromechanical structure having a deformable membrane and a protection against strong deformations

A technology of micro-machines and diaphragms, applied in the direction of micro-structural devices composed of deformable elements, micro-structural technology, micro-structural devices, etc., can solve problems such as damage, structural cracking, and easily damaged diaphragms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

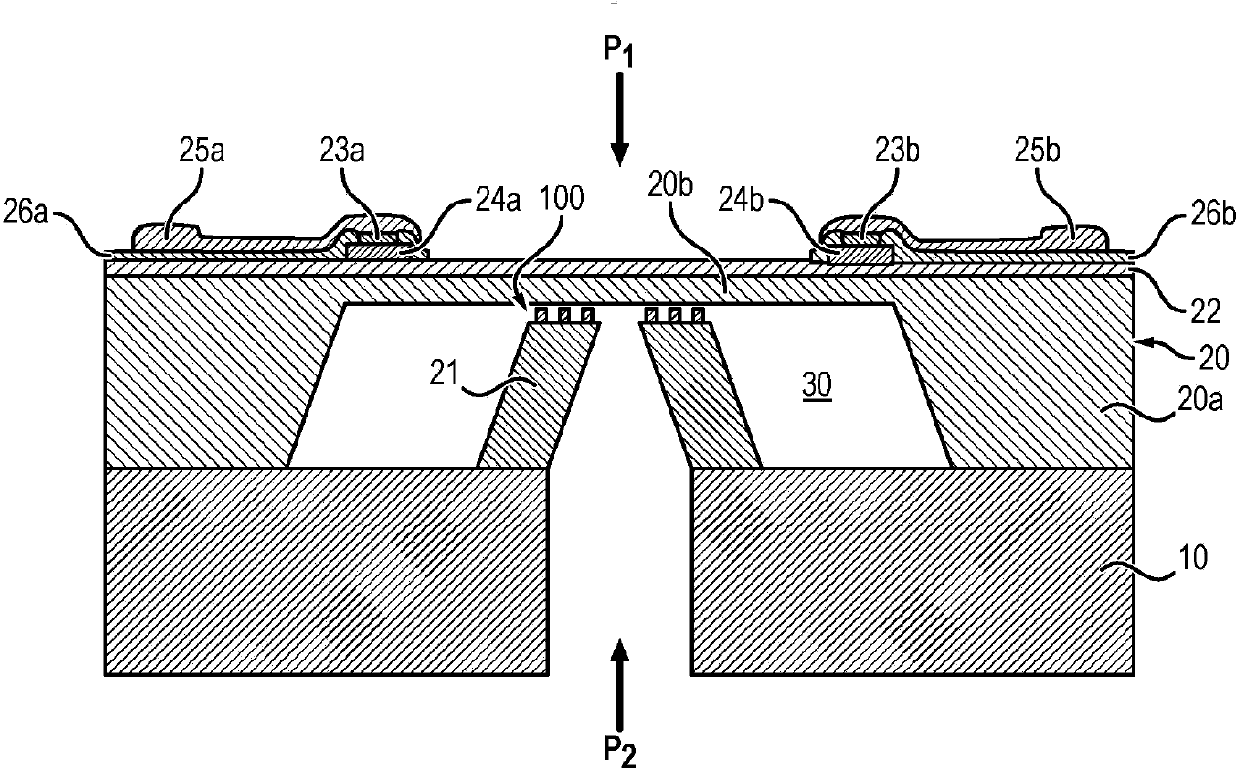

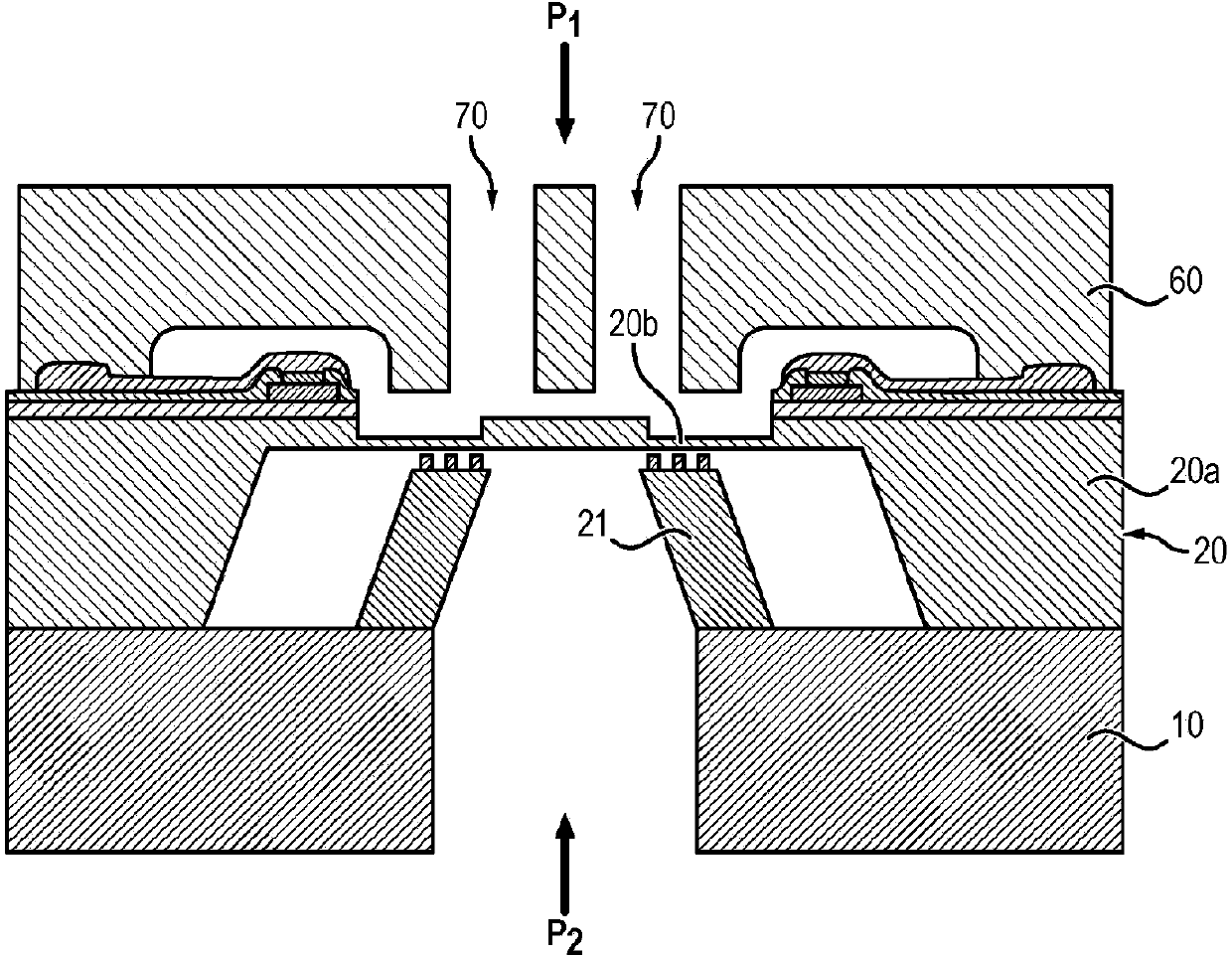

[0038] The micromechanical mechanism is intended to measure or detect mechanical or dynamic quantities such as pressure, said micromechanical mechanism comprising a deformable diaphragm 20 and a support substrate 10 .

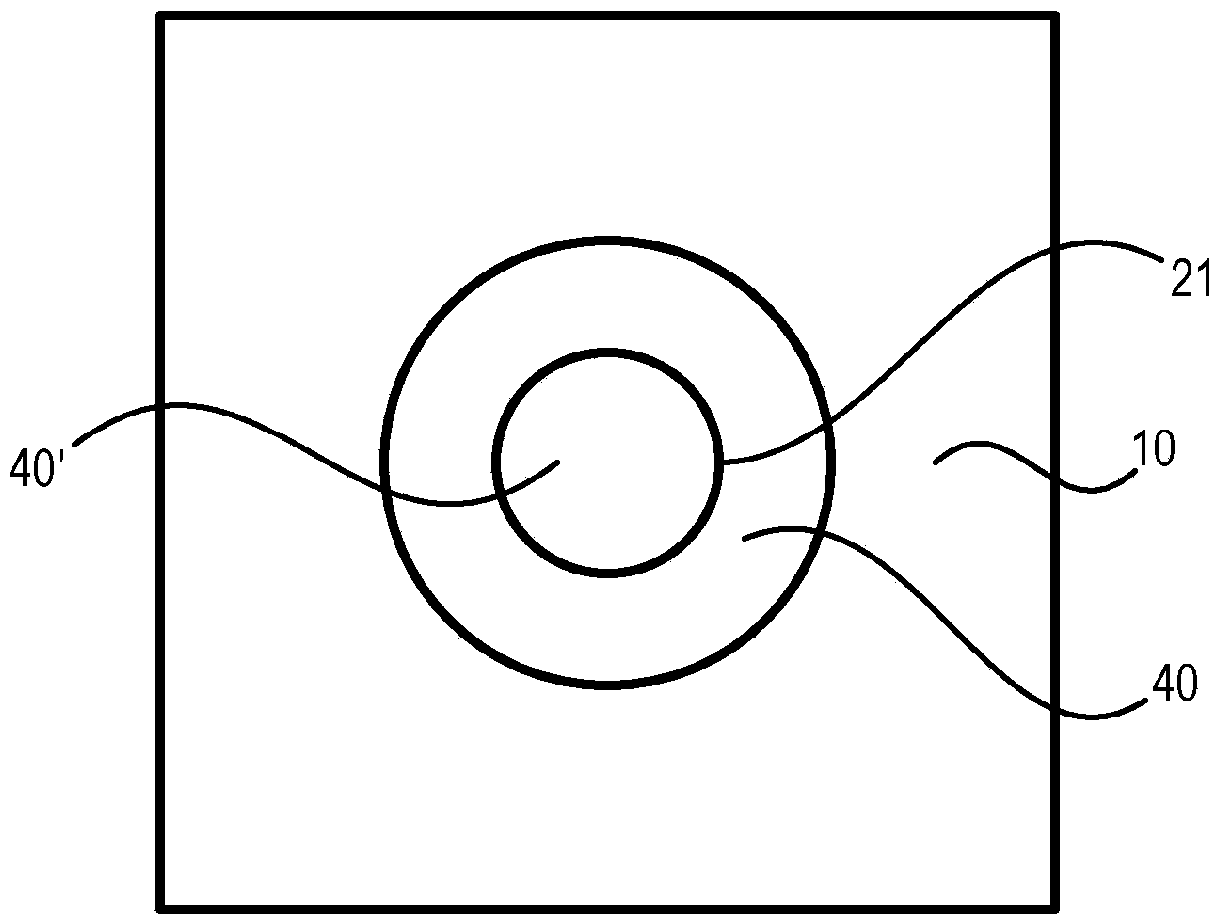

[0039] as in figure 1 , figure 2 and Figure 4 As shown in , the diaphragm is arranged on the support substrate 10 to define a free space 30 . In the case of a micromechanical mechanism for differential pressure measurement, this free space 30 is intended to be filled with a fluid. In this case, the pressure P1 comes from above the structure and the pressure P2 comes from below the structure (see figure 1 , figure 2 and Figure 4 ).

[0040] The diaphragm 20 is intended to support the pressure measuring cells 22, 23a, 23b, 24a, 24b, 25a, 25b, 26a, 26b.

[0041] Free space 30 is typically formed in the initial substrate by micromachining. The micromachining technique used to form such free spaces may be, for example, chemical etching, eg KOH etching at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com