Curing method of curable silicone composition

A curing method and silicone technology, applied in the direction of adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problem of poor curing reliability of the shading part, and achieve the effect of preventing poor curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

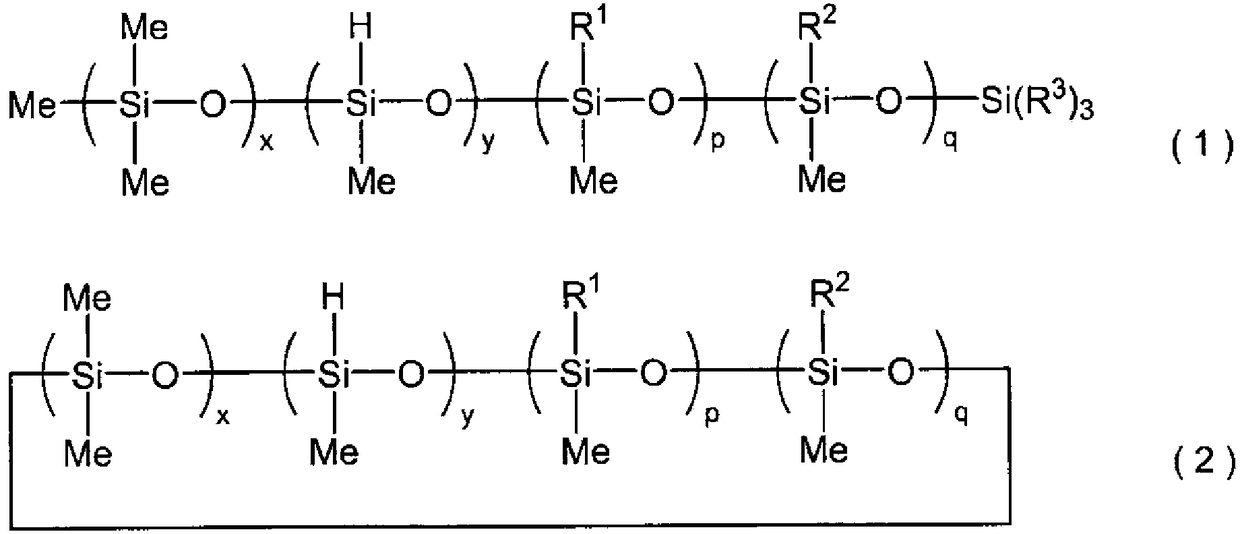

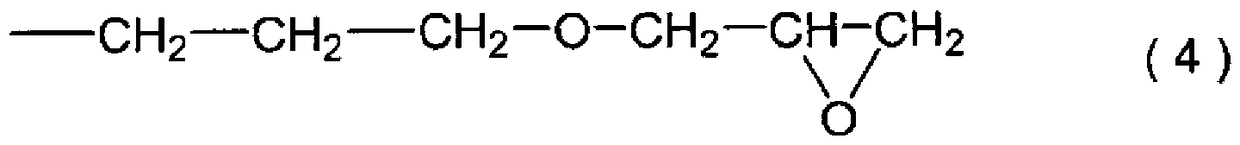

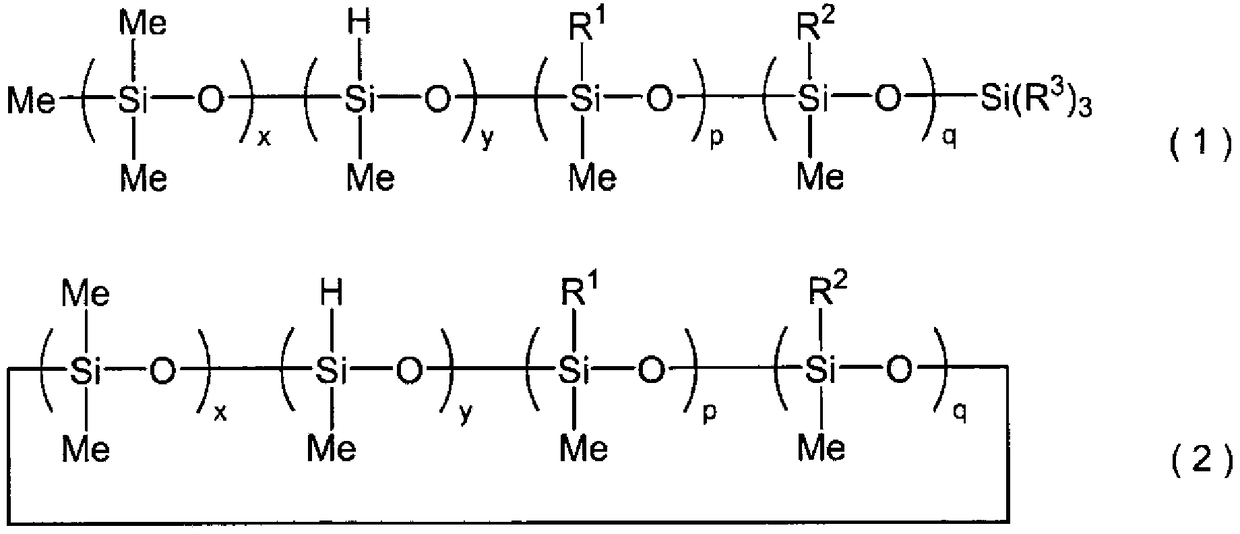

Method used

Image

Examples

Embodiment 1~5

[0135] The above components (A) to (D) were mixed as shown in Table 1 to prepare silicone compositions S1 to S5.

[0136] [Table 1]

[0137]

[0138] Using the prepared silicone compositions S1 to S5, curability (flow stop time, curing time, hardness), optical properties, and adhesive force were evaluated. The results are shown in Table 2. In addition, an ultraviolet uniform irradiation unit (SP-V SPOT CURE manufactured by Usio Denki Co., Ltd.) was used for ultraviolet irradiation.

[0139] (Evaluation method)

[0140] Flow stop time:

[0141] After applying the silicone composition to a glass dish so that the height becomes 1 cm, and irradiating ultraviolet rays so as to obtain a predetermined irradiation dose, the glass dish was tilted by 90°, and the time until the silicone composition stopped flowing was measured.

[0142] Curing time:

[0143] Apply the silicone composition to a glass dish so that the height becomes 1cm, and ultraviolet rays (irradiation amount 5,...

Embodiment 6

[0153] Using the silicone composition S2, a dark part curing test was carried out. The test method is shown below.

[0154] Dark curing test:

[0155] An aluminum dish with a diameter of 6 cm was filled with the silicone composition S2 so as to have a height of 6 mm, and it was covered with a black sheet that did not transmit light having a hole of 2 cm square. From a 2cm square hole, use an ultraviolet uniform irradiation unit (SP-V SPOT CURE manufactured by Usio Denki Co., Ltd.) to irradiate ultraviolet rays (irradiation dose: 5,000mJ / cm 2 ), after curing for a specified time at 25°C and 70°C, measure the cured area for evaluation. The results are shown in Table 3.

Embodiment 7

[0161] Using the silicone composition S2, a transparent resin interfacial curing test was carried out. The test method is shown below. As the transparent resin, polyacrylic resin (hereinafter, PMMA) (Clarex 001 クリヤー manufactured by Nitto Jushi Kogyo Co., Ltd.), polycarbonate resin (hereinafter, PC) (パンライトイート PC1151 manufactured by Teijin Corporation), and polyterephthalic acid were used. Ethylene glycol ester resin (hereinafter, PET) (SUPER PET PLATE 6010 manufactured by Takiron Corporation).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com