A hot air circulation oven

A technology of hot air circulation oven and heating tube, applied in heat treatment equipment, heat treatment process control, manufacturing tools and other directions, can solve the problems of not meeting the heat treatment requirements, poor heating uniformity of the oven, etc., to improve automatic control performance and heating uniformity. Improve and improve the effect of temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

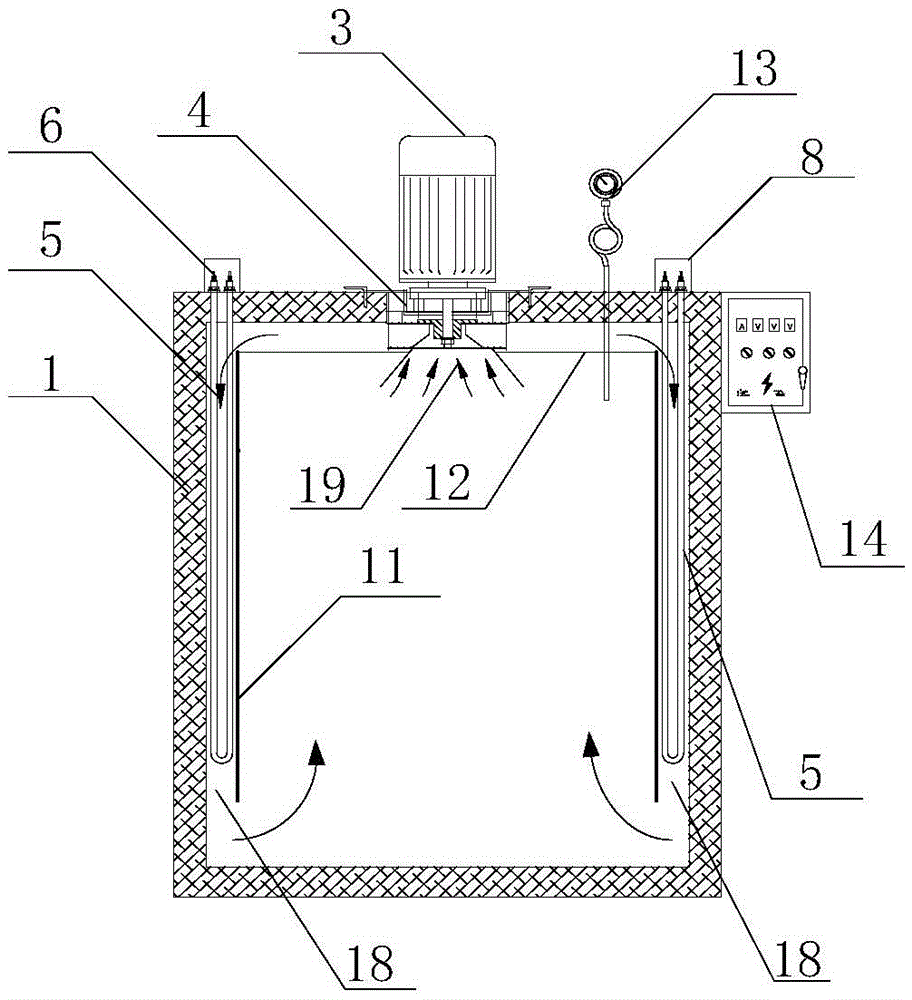

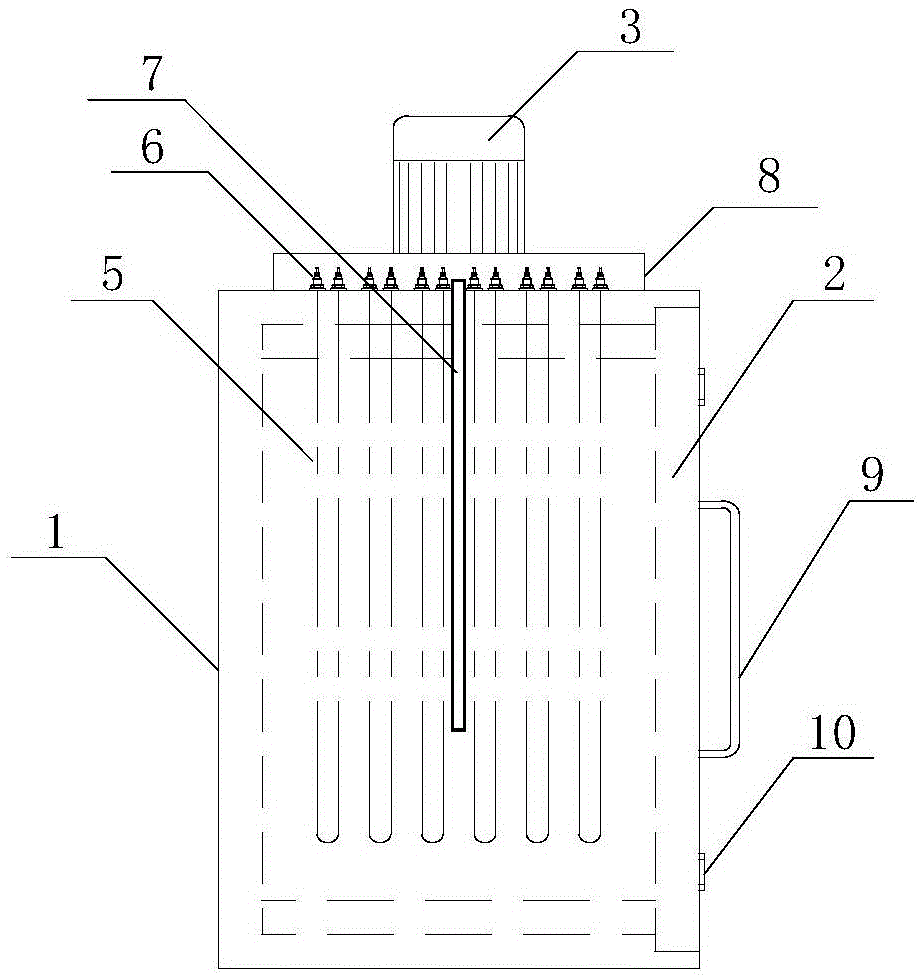

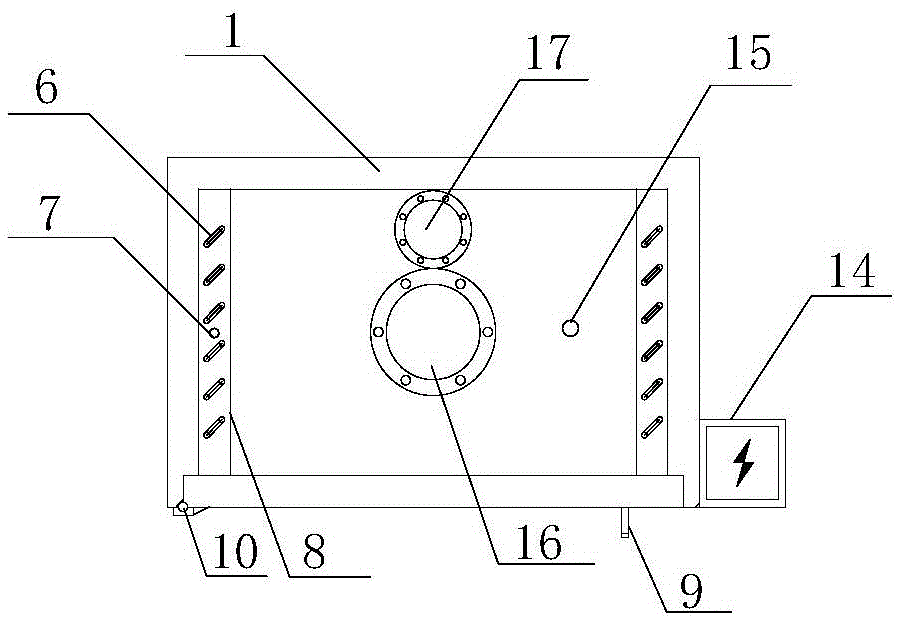

[0022] Such as Figure 1-3 As shown, the hot air circulation oven of the present invention includes an insulated box body 1, an insulated door 2, a drive motor 3, a temperature measuring tube 7 and at least two U-shaped heating tubes 5, and the insulated door 2 is rotatably installed in the insulated box body through a hinge 10. 1, the left and right sides of the insulated box 1 are provided with side partitions 11, the top of the insulated box 1 is provided with a top partition 12, and the side partitions 11 and the top partition 12 are connected with the insulated box. The left and right side walls and the top wall of 1 together form a "door"-shaped cavity. The side partition 11 is provided with an air outlet 18 near the bottom of the insulation box 1, and the top partition 12 is provided with an air inlet 19. Temperature measurement Both the tube 7 and the U-shaped heating tube 5 are inserted into the cavity between the side partition 11 and the left and right side walls of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com