Anti-airlock oil well pump

An oil well pump and anti-air technology, which is applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve the problems of reducing production, reducing the filling coefficient of oil well pumps, affecting production, etc., and achieve the effect of increasing production and preventing air lock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention will not be limited.

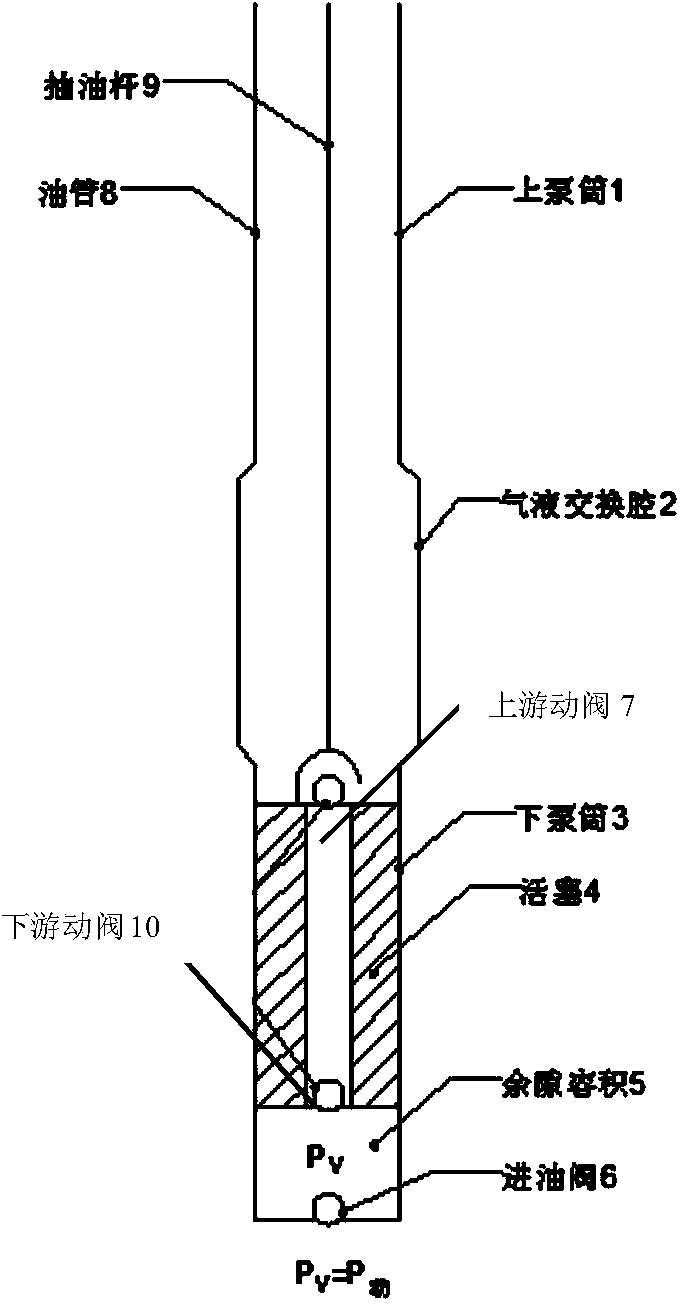

[0013] Such as figure 1 As shown, the anti-airlock oil well pump of the present invention comprises a cylindrical upper pump barrel 1, a gas-liquid exchange chamber 2 and a lower pump barrel 3; , the top of the upstream floating valve 7 is connected with a sucker rod 9; the center of the bottom of the lower pump barrel 3 is provided with a spherical oil inlet valve 6. The gas-liquid exchange chamber set between the upper pump barrel and the lower pump barrel is cylindrical, and the piston arranged inside the pump barrel cooperates with the inner surface of the upper pump barrel and the lower pump barrel to seal, and the inner surface of the gas-liquid exchange chamber is sealed. There is an annular space in between.

[0014] The function of the gas-liquid exchange chamber 2 (hereinafter referred to as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com