Compressor pump body structure and compressor

A technology for compressors and pumps, applied in machines/engines, components of pumping devices for elastic fluids, rotary piston/oscillating piston pump components, etc., can solve the problems of contact, increased power consumption, roller and flange gap reduction, etc., to achieve the effect of increasing basic strength, reducing power consumption, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

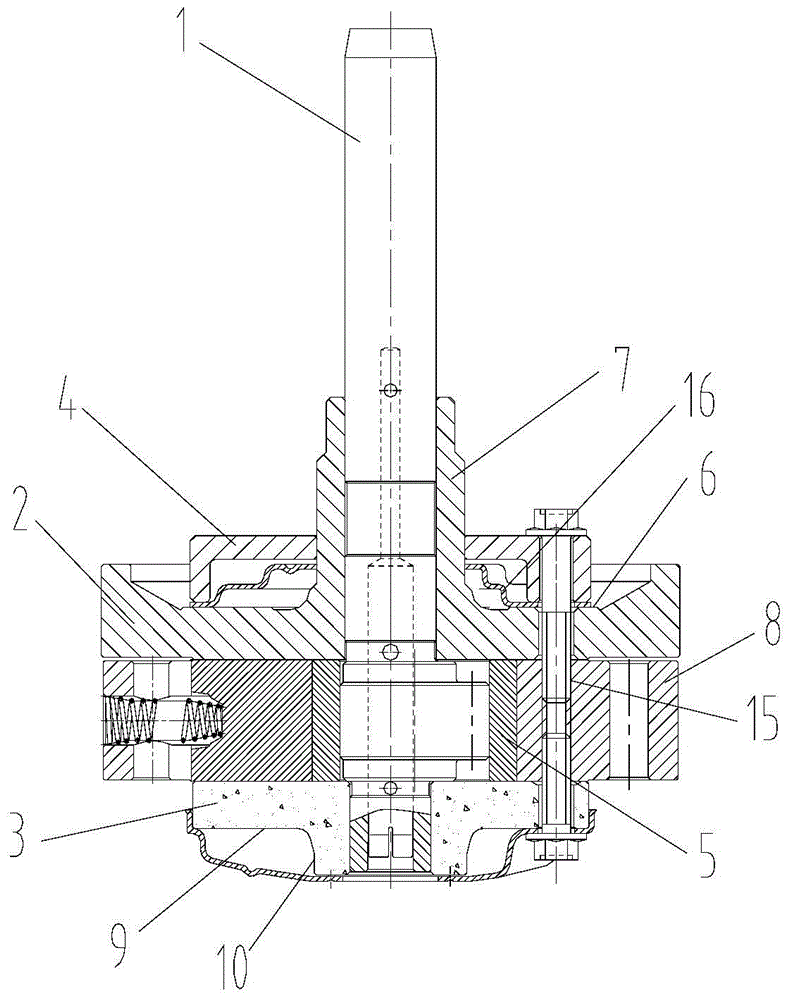

[0030] Such as figure 1 , 2 As shown, a pump body structure of a compressor includes: crankshaft 1, upper flange 2, lower flange 3, roller 5, cylinder 8 and support 4; upper flange 2 and lower flange 3 are set on On the crankshaft 1, the upper flange 2 and the lower flange 3 are fixedly connected with the cylinder 8, and the roller 5 is arranged between the upper flange 2 and the lower flange 3; the upper flange 2 includes the non-working surface 6 of the upper flange, The lower flange 3 includes the non-working surface 9 of the lower flange; the non-working surface 6 of the upper flange is the surface of the upper flange 2 facing away from the roller 5, and the non-working surface 9 of the lower flange is the surface of the upper flange 3 facing away from the roller 5 The support member 4 abuts on the non-working surface 6 of the upper flange and / or the non-working surface 9 of the lower flange, and is fixedly connected with the upper flange 2 and / or the lower flange 3 .

...

Embodiment 2

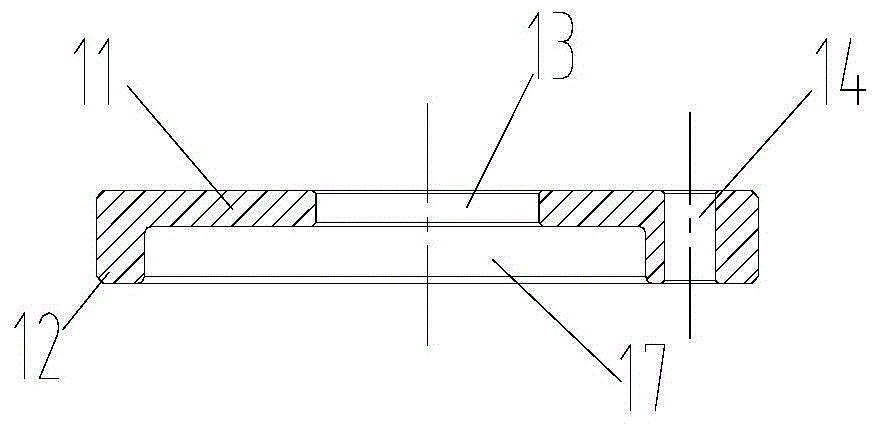

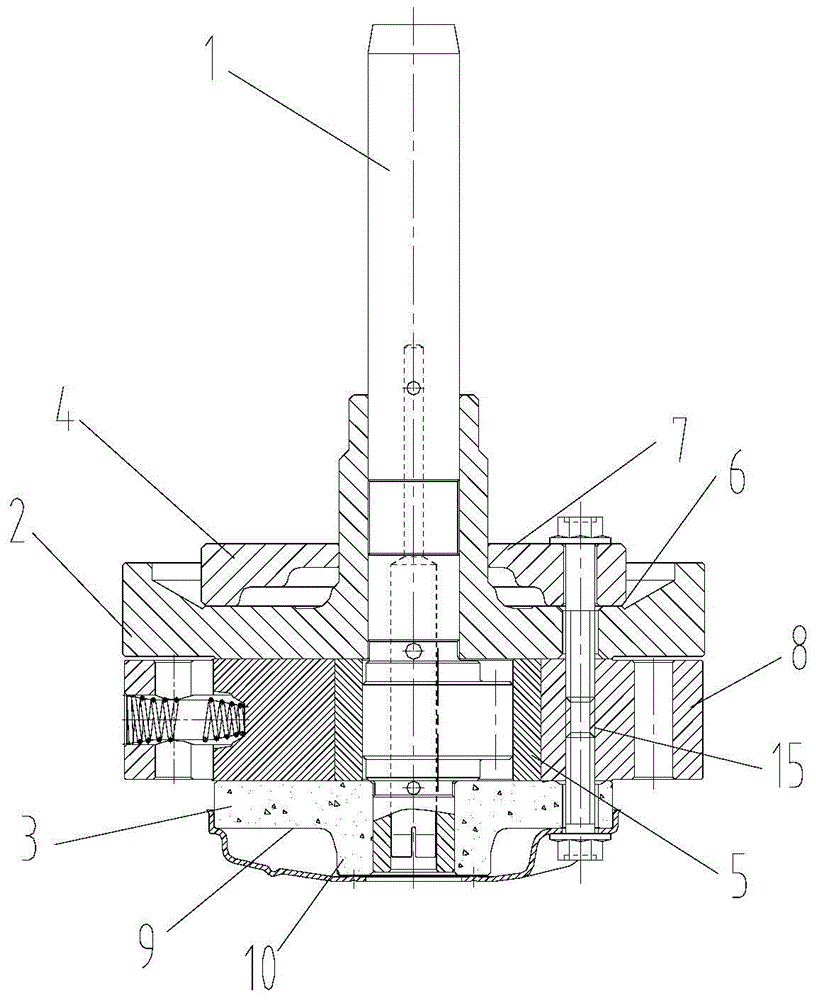

[0037] Such as image 3 , 4 As shown, this embodiment has the same structural features as the first embodiment, and the difference from the first embodiment is that the muffler 16 is omitted, and the inner wall of the accommodating space 17 is a step formed by a smooth curved surface. The inner wall of the accommodating space 17 is a step formed by a smooth curved surface. The design of the step formed by this smooth curved surface is the same shape as that of the inner wall of the muffler 16 in the embodiment, so that the passing air flow can be guided to achieve Noise reduction effect. In this way, the supporting member 4 can not only support the upper flange 2 and / or the lower flange 3, but also can silence the compressor, which saves the cost.

[0038] The present invention also provides a compressor, including the pump body structure of the compressor described in any of the above embodiments.

[0039] The invention has the advantages of reasonable design, simple struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com