Induced draught fan and boost fan combined control method for large thermal generator set

A technology for thermal power generating units and booster fans, applied in pump control, machines/engines, mechanical equipment, etc., can solve the problems of high booster fan power, low FGD inlet pressure, large safety margin, etc., and achieve responsive working conditions Effects of changing, stabilizing and optimizing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

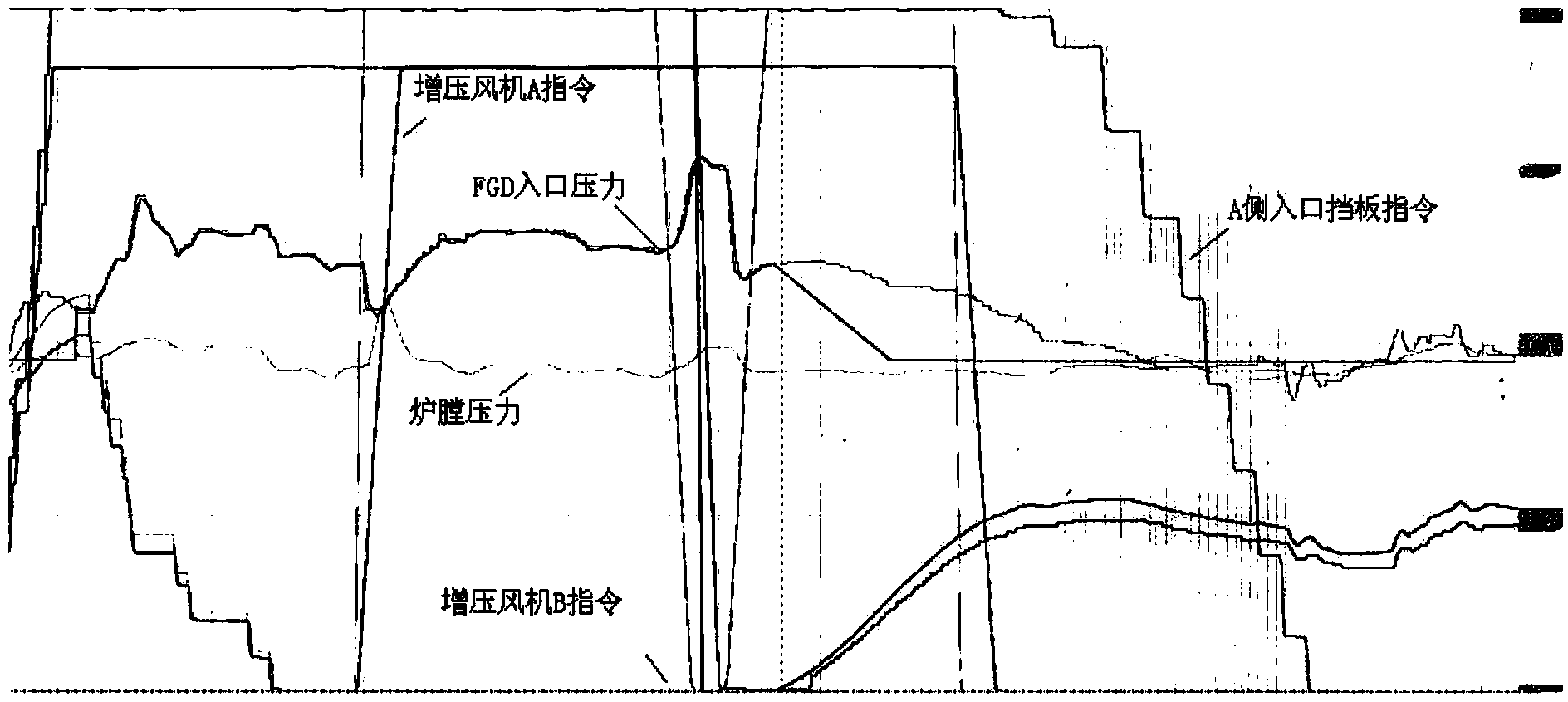

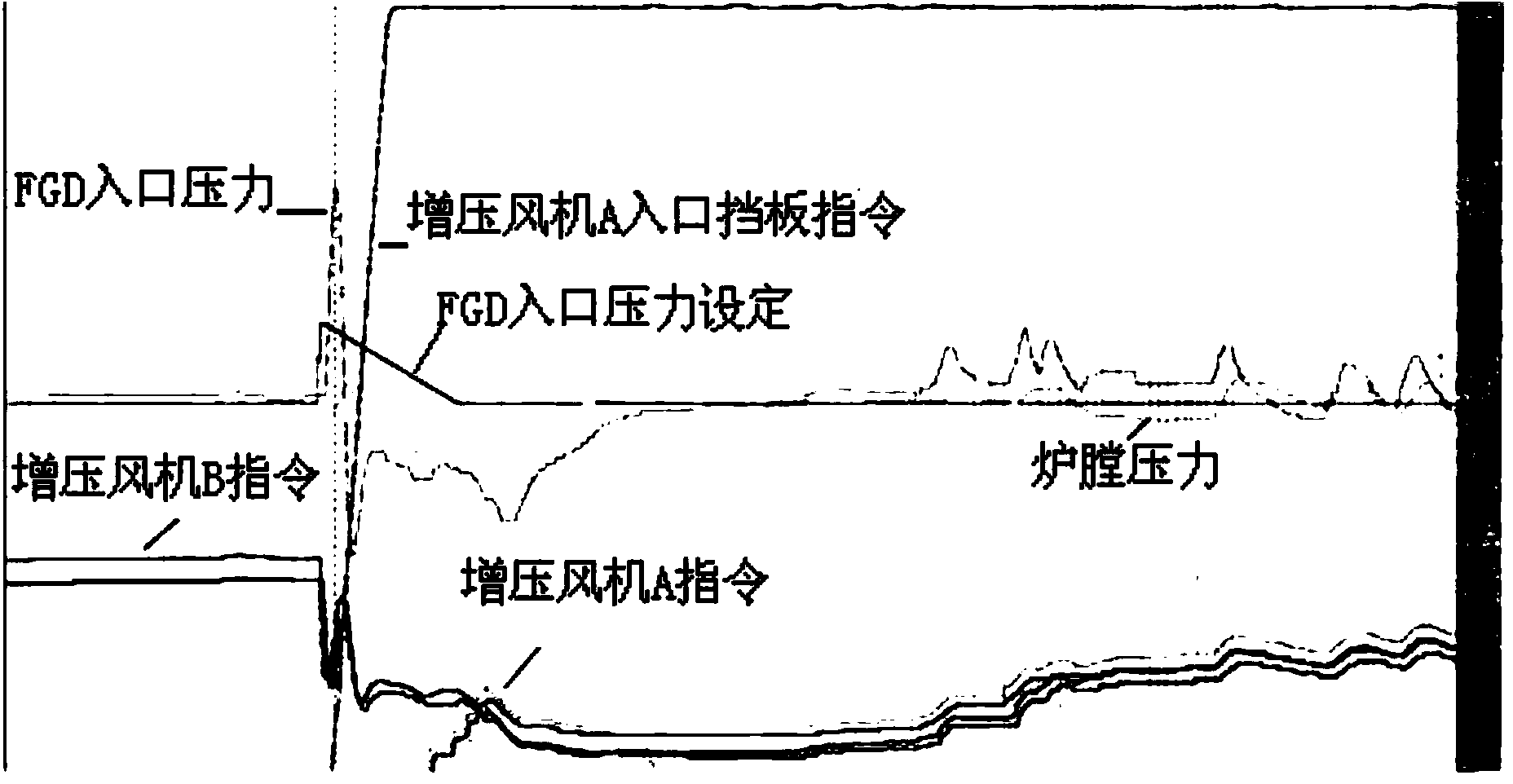

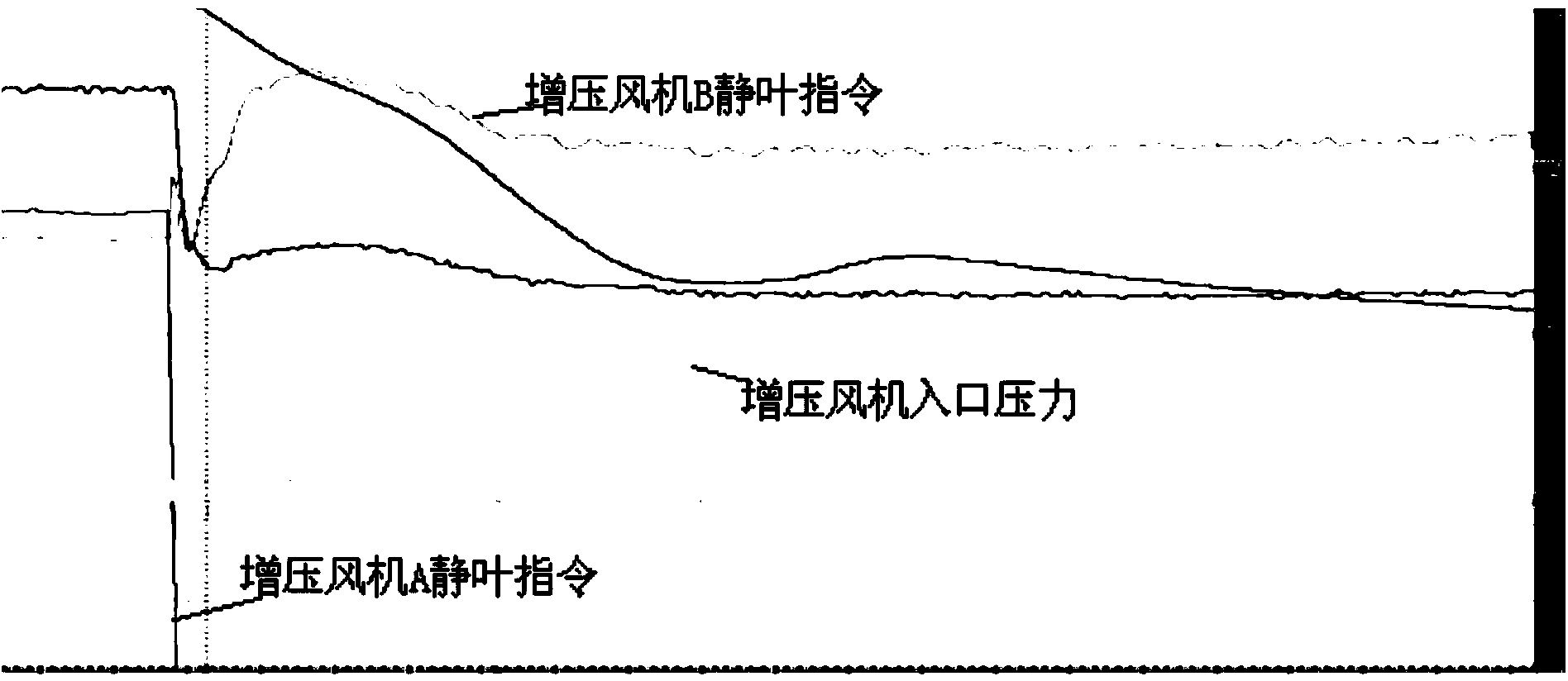

Examples

Embodiment Construction

[0029] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0030] For clarity, the descriptions, abbreviations or abbreviations of the technical terms used in the following are summarized as follows:

[0031] Furnace Negative Pressure: The furnace negative pressure is a parameter reflecting the pressure in the furnace. There are two ways to express pressure: one is called absolute pressure (also known as real pressure), which is the pressure value obtained from absolute vacuum as the starting point of measurement. The other is called relative pressure, which is the pressure value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com