Light guide column and lamps

A technology of light guide columns and lamps, which is applied in the direction of optics, light guides, light sources, etc., can solve the problems of small irradiation space, small light angle, and difficult injection molding, so as to ensure external aesthetics, improve distribution angle, and simple injection molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

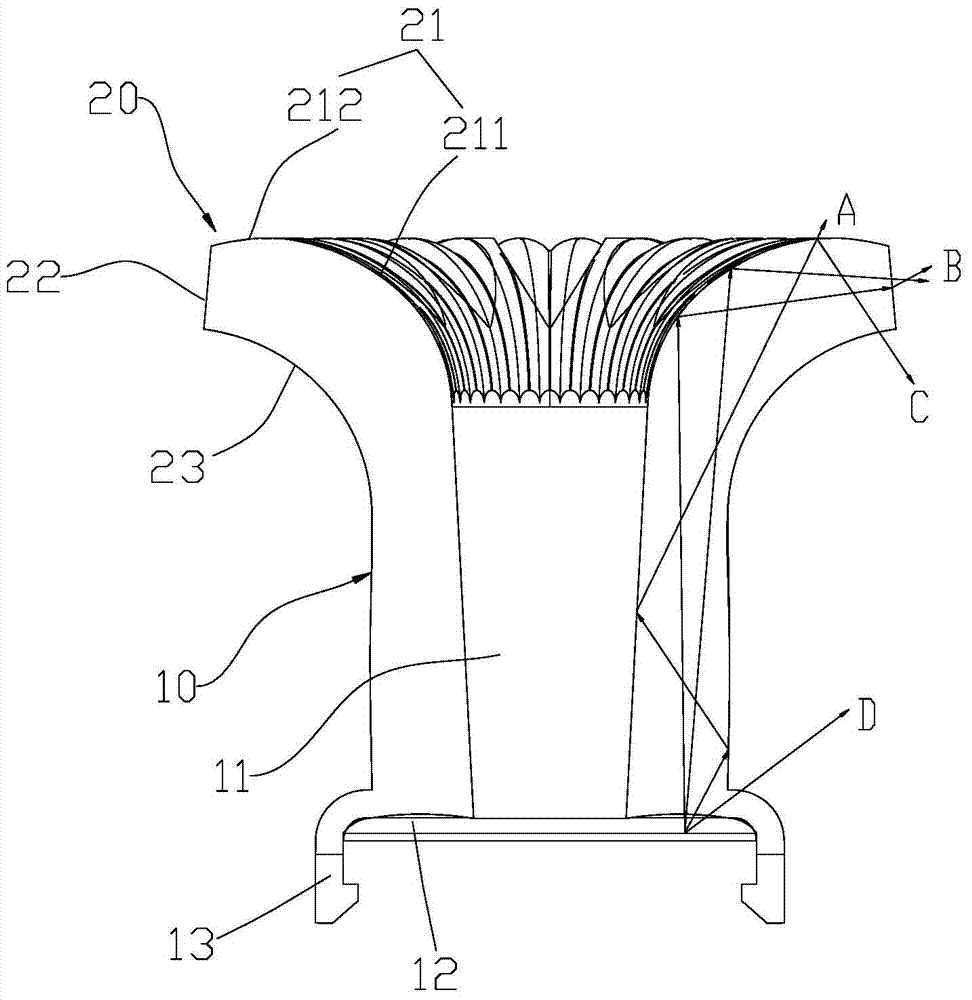

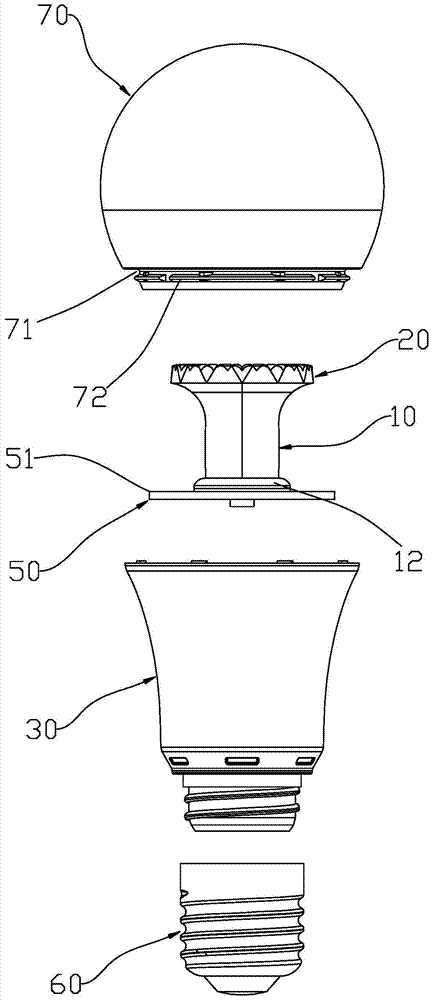

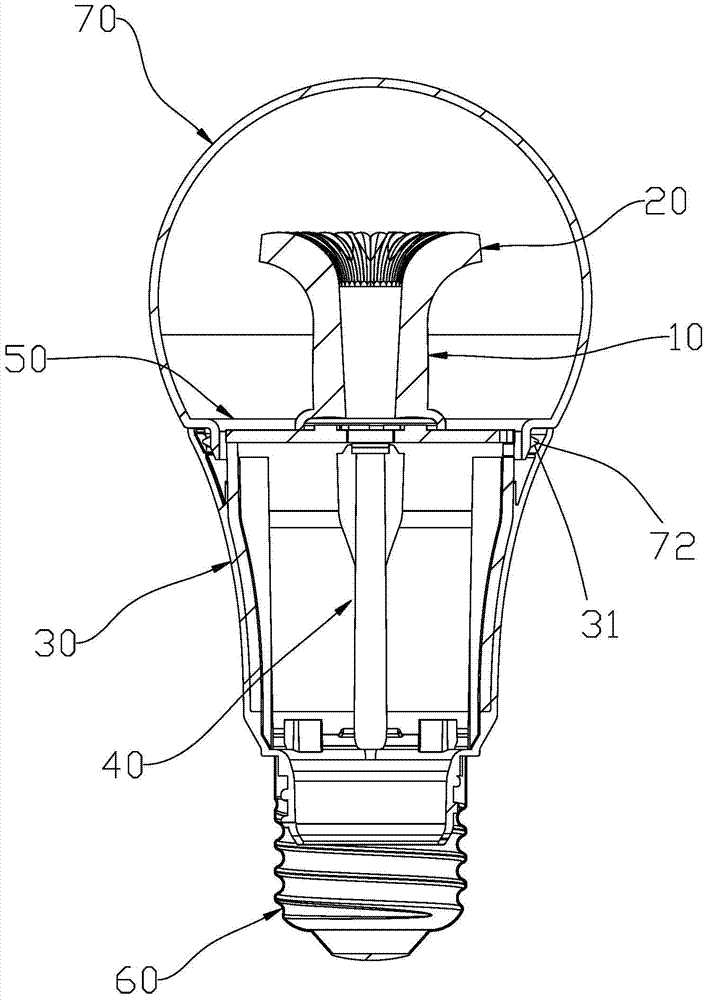

[0026] The light guide column of the present invention is used for distributing light emitted by a light source, and can be applied to a lamp to increase the light emitting angle of the lamp. Such as figure 1 As shown, it is a cross-sectional view of a light guide column according to an embodiment of the present invention. The light guide column includes a light guide column body 10 and a light exit portion 20. The middle part of the light guide column body 10 is provided with a bottom-up through hole 11, so that the light guide column body 10 is a hollow structure (such as figure 1 shown). The light exit part 20 is formed by bending and extending from the top of the light guide cylinder 10 to a direction away from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com