A control device for slag heat exchange equipment

A technology of a control device and a heat exchange device, which is applied to heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low recovery efficiency, limited promotion and application, waste of heat energy, etc., and achieves convenient installation and operation, simple overall structure, The effect of improving the heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

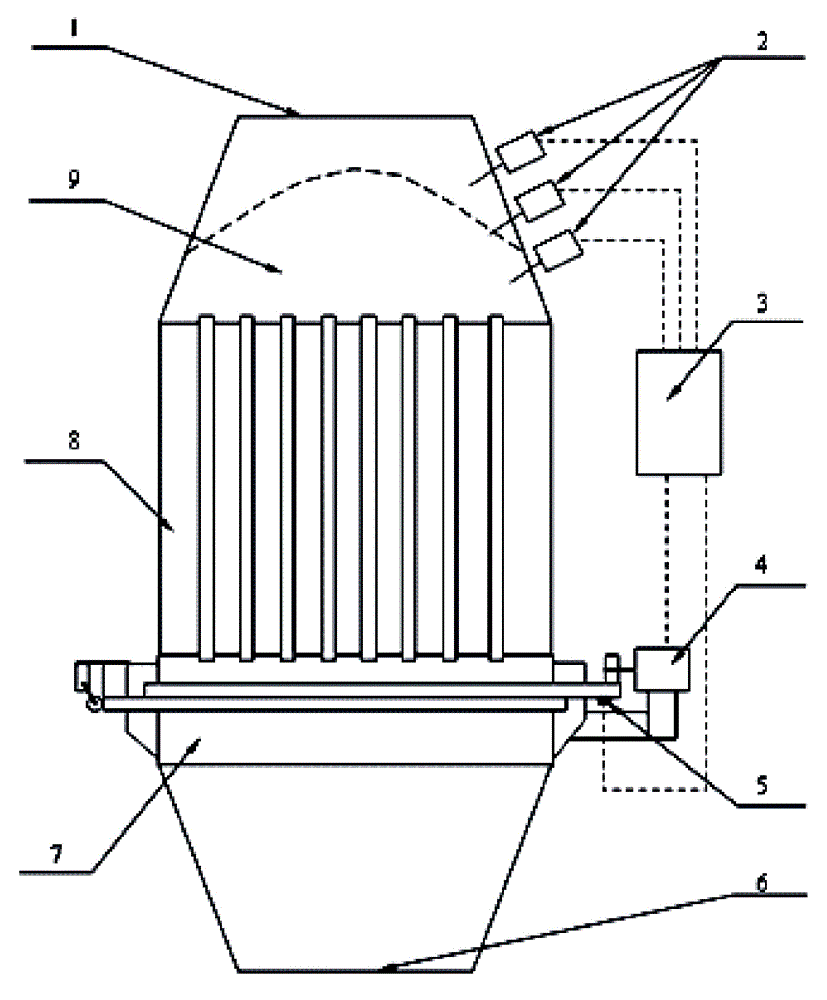

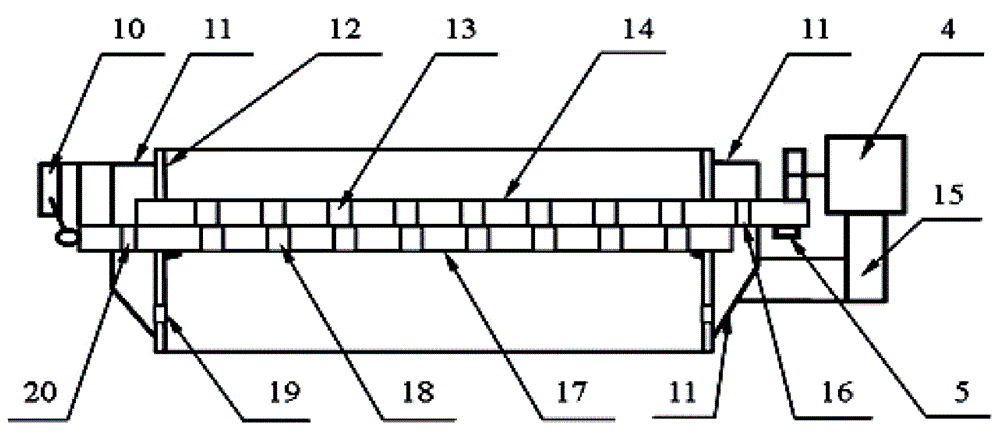

[0007] Now refer to the attached figure 1 And attached figure 2, the description is as follows in conjunction with the embodiment: A control device for slag heat exchange equipment according to the present invention includes a slag inlet 1, a level meter 2, a controller 3, a control motor 4, a position feedback device 5, an outlet Slag port 6, slag inlet and outlet control device 7, slag heat exchange device 8, high temperature slag bin 9, vibration device 10, sealing device 11, shell 12, upper slag outlet hole 13, upper regulating plate 14, fixing device 15, right end seal Use the slag hole 16, the lower adjusting plate 17, the following slag hole 18, the slag hole 19 and the left end sealing with the slag hole 20. The slag heat exchange device 8 is the main part of a control device used for slag heat exchange equipment according to the present invention. A slag entry and exit control device 7 is arranged under the slag heat exchange device 8, and a slag entry and exit cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com