Strain gauge based on magnetorheological elastomer

A magnetorheological elastomer and strain gauge technology, applied in the field of strain gauges, can solve the problems of narrow application range, complicated manufacturing process, and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

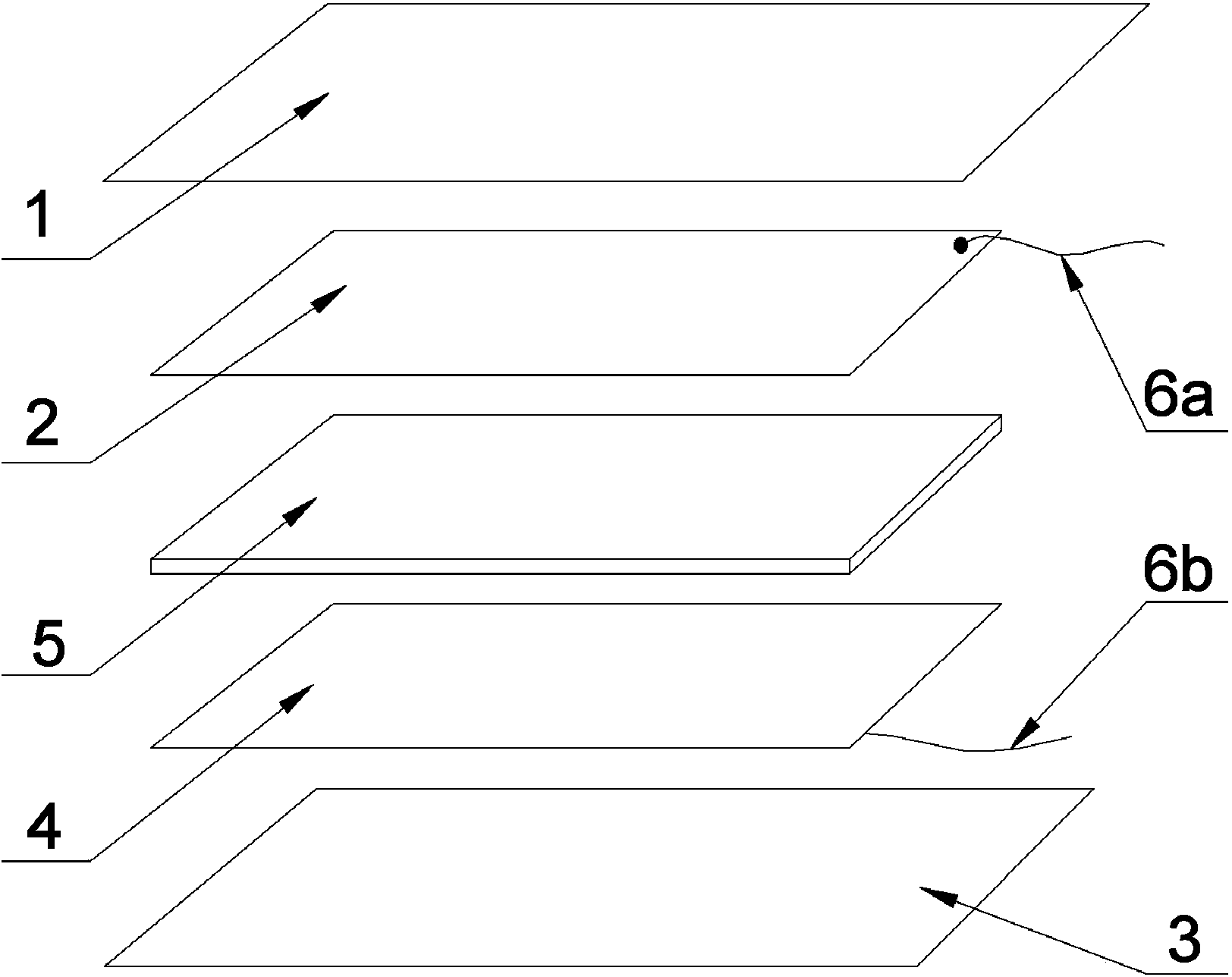

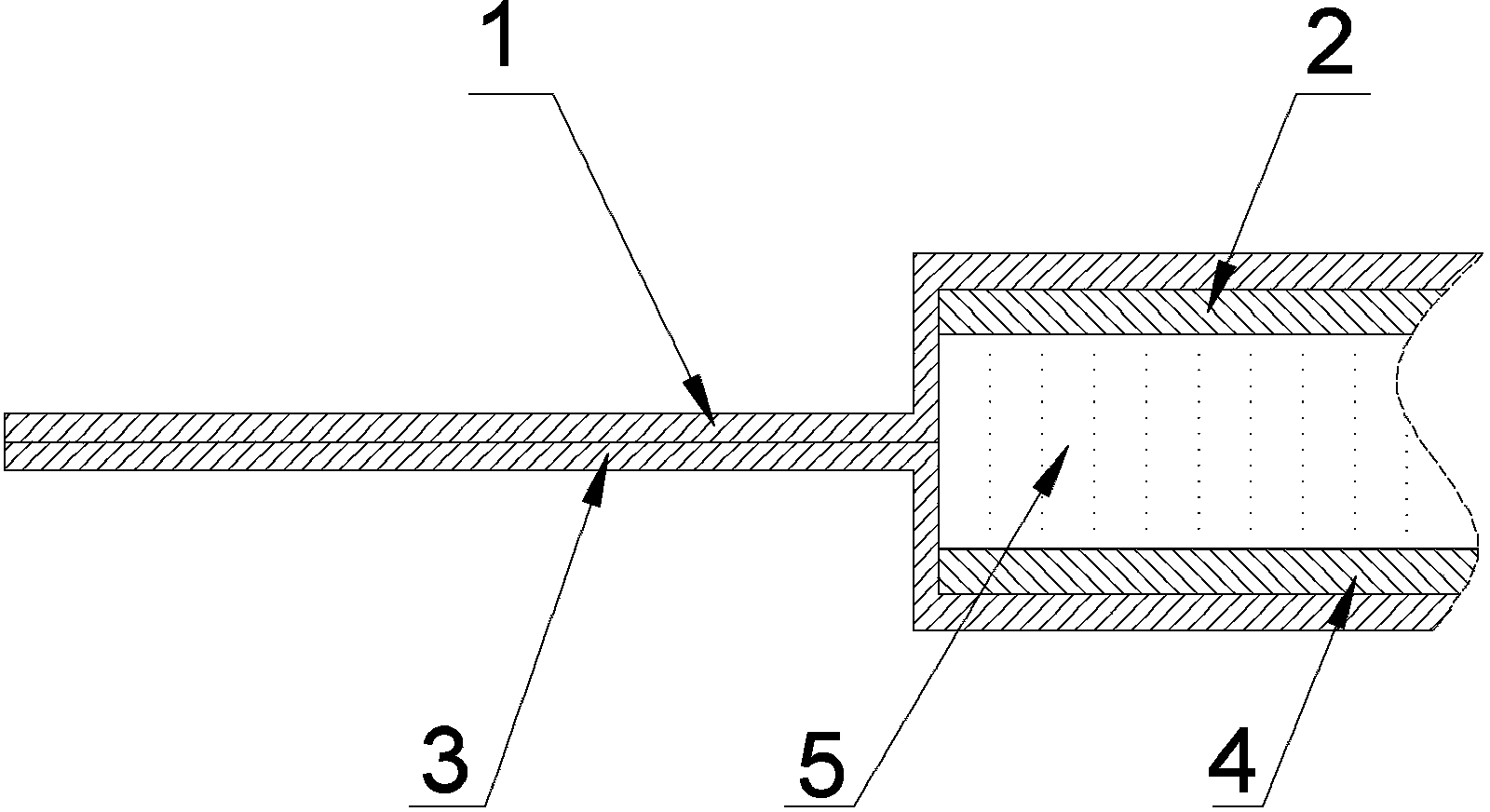

[0016] see figure 1 , is an embodiment of a strain gauge based on a magnetorheological elastomer, including an upper insulating film 1 and a lower insulating film 3. In this embodiment, both the upper insulating film 1 and the lower insulating film 3 are polymer films, Both the upper insulating film 1 and the lower insulating film 3 have a thickness of 15-25 um, and in this embodiment, the upper insulating film 1 and the lower insulating film 3 both have a thickness of 20 um. The lower surface of the upper insulating film 1 is pasted and fixed with an upper electrode sheet 2, and the upper lead wire 6a is welded and fixed on the upper electrode sheet 2. The welding point of the upper lead wire 6a is located between the upper electrode sheet 2 and the upper insulating film 1, and the sealing performance is good. Prevents interference with magnetorheological elastomers. The upper surface of the lower insulating film 3 is pasted and fixed with the lower electrode sheet 4, the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com