Electric actuator detection device and detection method thereof

A technology of electric actuators and detection devices, applied in measuring devices, instruments, linear/angular velocity measurement, etc., can solve the problems of high cost and no testing ability of integrated torque sensors, and achieve saving pipeline assembly process requirements and avoiding torque The effect of measurement error and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

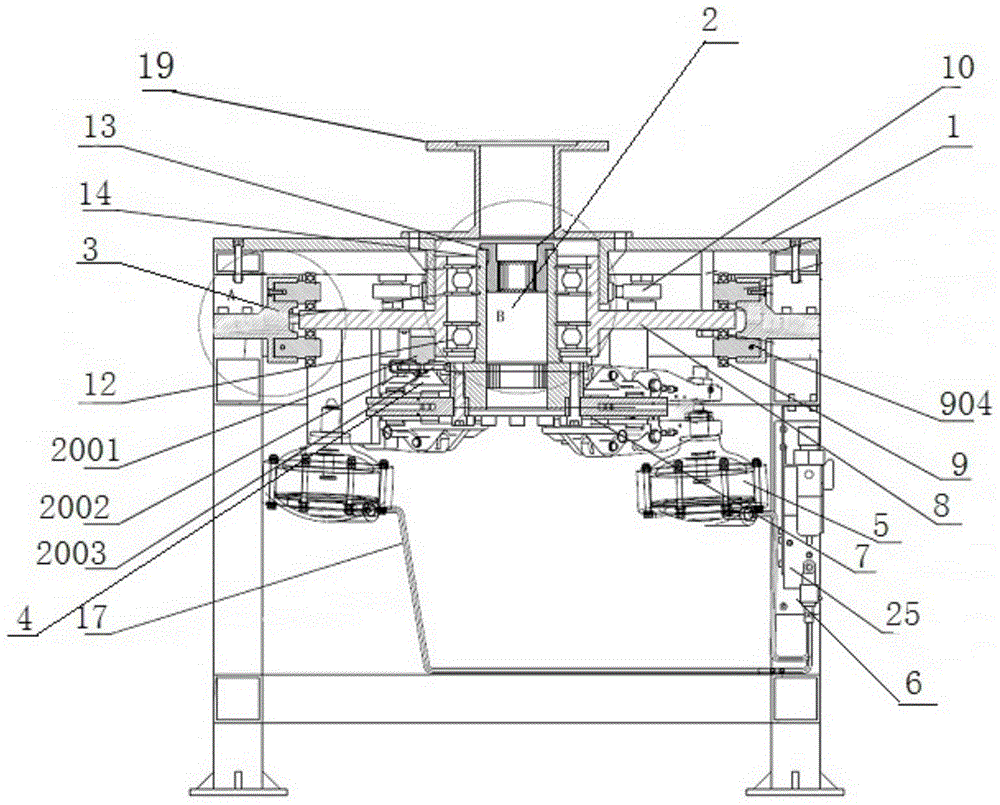

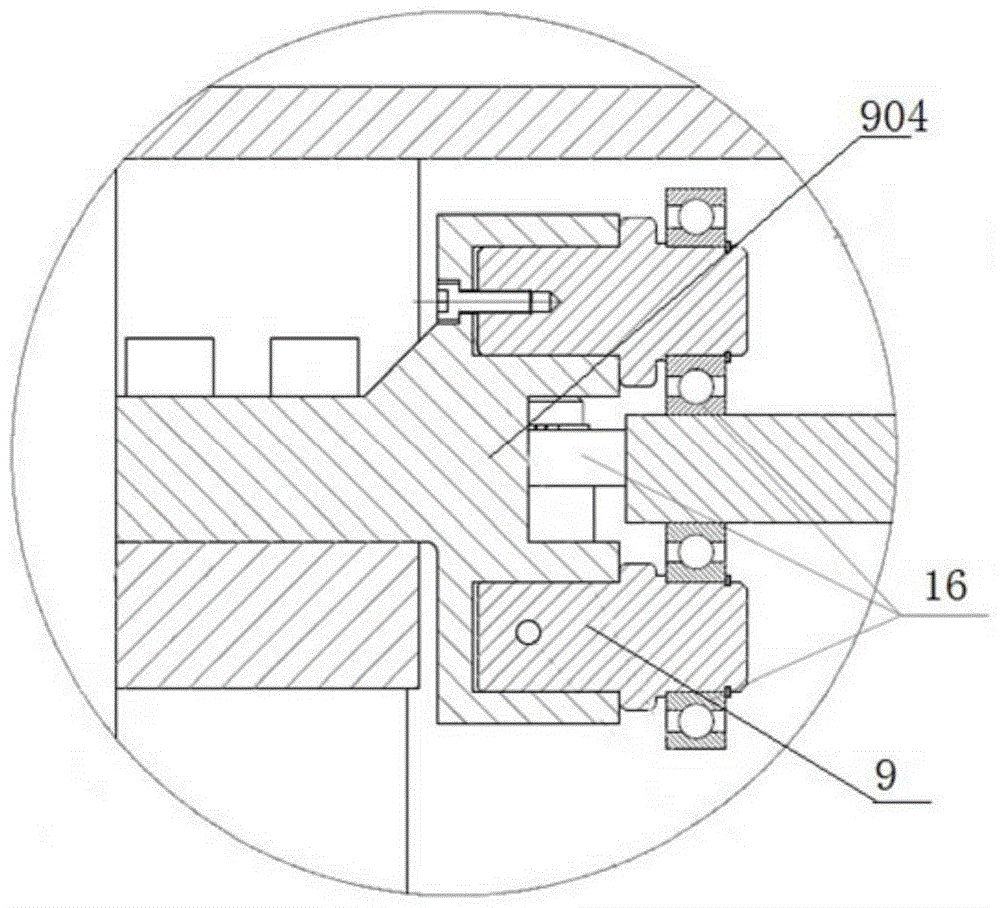

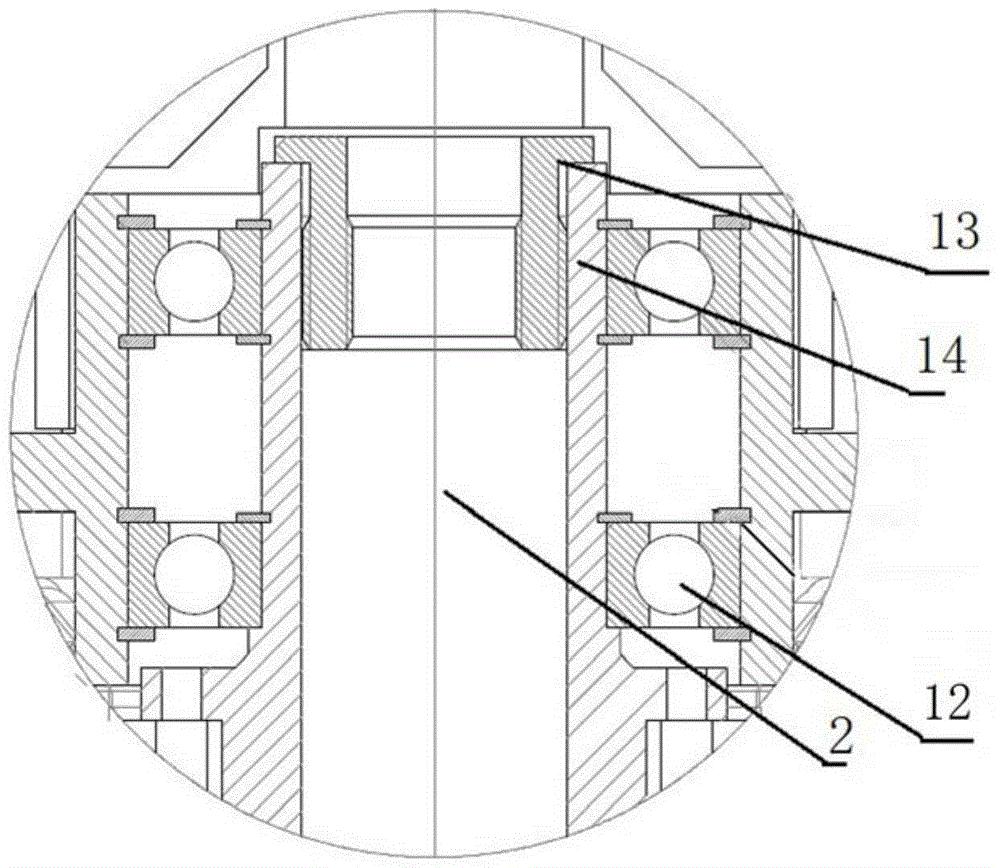

[0051] Such as Figure 1 to Figure 8 As shown, a detection device for an electric actuator provided by the present invention is used to measure the torque and rotational speed of the electric actuator. In the main bracket 1, connected to the output end of the transmission shaft of the electric actuator, a transmission system 2 that transmits torque through a friction loading mechanism;

[0052] Connected with the output end of the transmission system 2, the torque feedback system 3 and the rotational speed feedback system 4 used to measure the output of the electric actuator; installed on the main support 1, connected with the friction loading mechanism of the transmission system 2, and providing clamping through the cylinder 5 Friction air path control system 6;

[0053] The input end of the transmission system 2 is connected coaxially with the transmission shaft of the electric actuator, and is the input shaft of the brake pad 7 of the friction loading mechanism;

[0054] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com