An Intelligent Piston Pressure Gauge Automatic Loading Structure

A piston pressure gauge and automatic loading technology, which is applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of piston sensitivity limitation, high load-bearing center of gravity, etc., and achieve high sensitivity, uniform force, and accurate bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

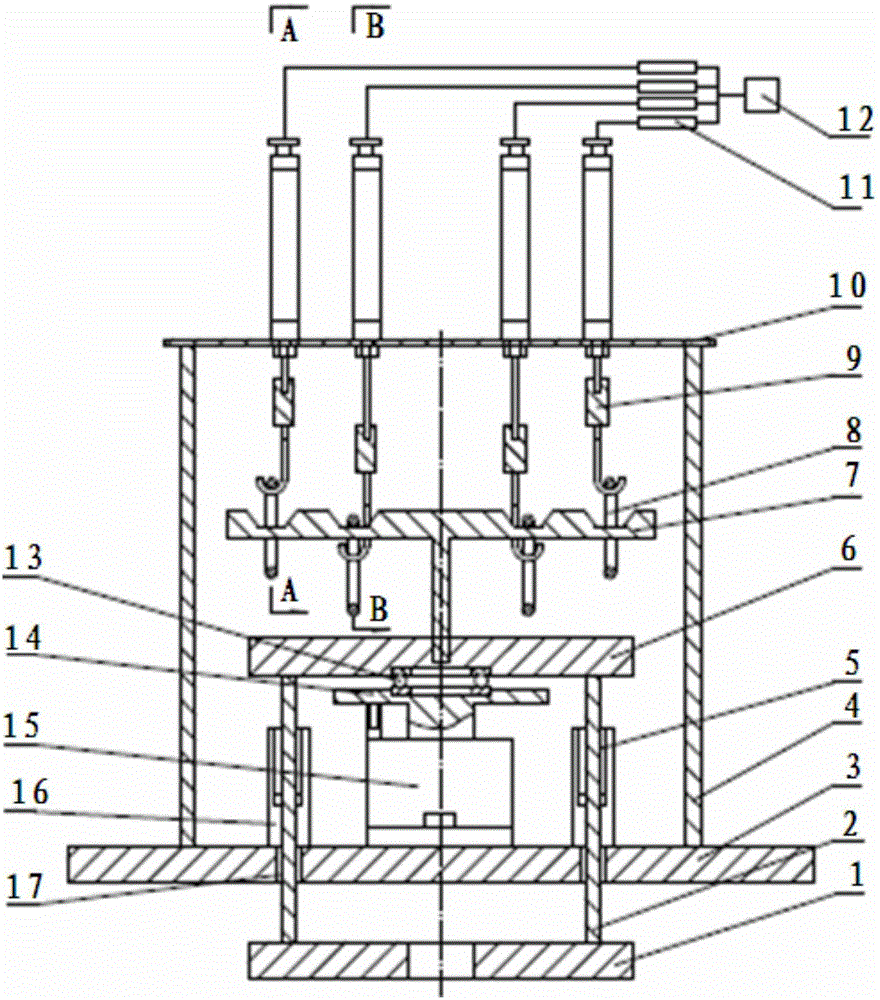

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

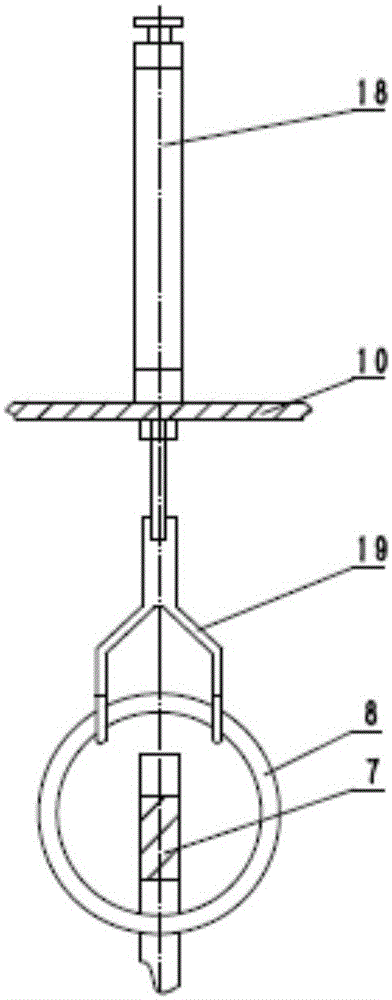

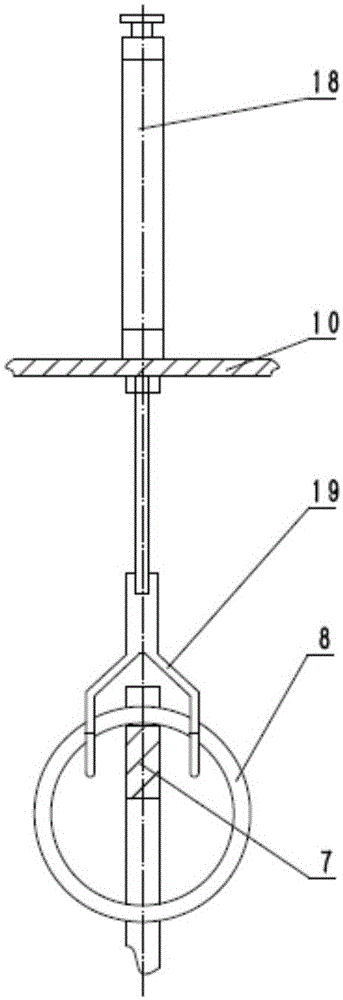

[0015] Such as figure 1 As shown, the present invention is driven by a base 3, a self-rotating piston assembly 15, an upper load-bearing beam 6, two load-bearing beam connecting rods 2, a lower load-bearing beam 1, a thrust bearing 13, a T-shaped weight pole 7, and four cylinders. Type double hook weight hanger 9, ring weight 8, two fixed plate poles 4, two limit rollers 5, two limit roller brackets 16, cylinder fixed plate 10, reversing solenoid valve 11 , which is characterized in that: an upper load-bearing beam 6 is provided above the piston assembly 15 capable of rotation, and a lower load-bearing beam 1 is provided below, and a through hole is provided in the center of the lower load-bearing beam 1; Root bearing beam connecting rod 2 is connected; The center of the piston disc 14 on the upper end of the piston assembly 15 capable of rotation and the center below the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com