Measuring structure and method for Young's modulus of thin film silicon material on insulating substrate

A technology for testing structures on an insulating substrate, applied in the direction of testing the strength of materials by applying a stable bending force, can solve problems such as instability, uncertain device design and performance prediction, and achieve simple test methods, test processes and test results. The effect of stable parameter value and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

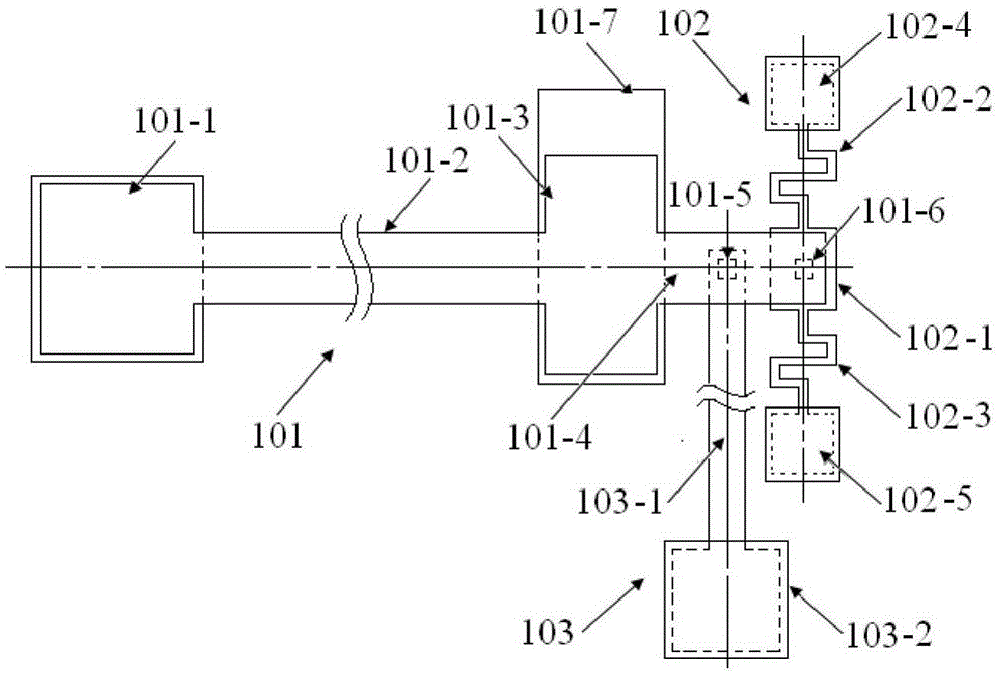

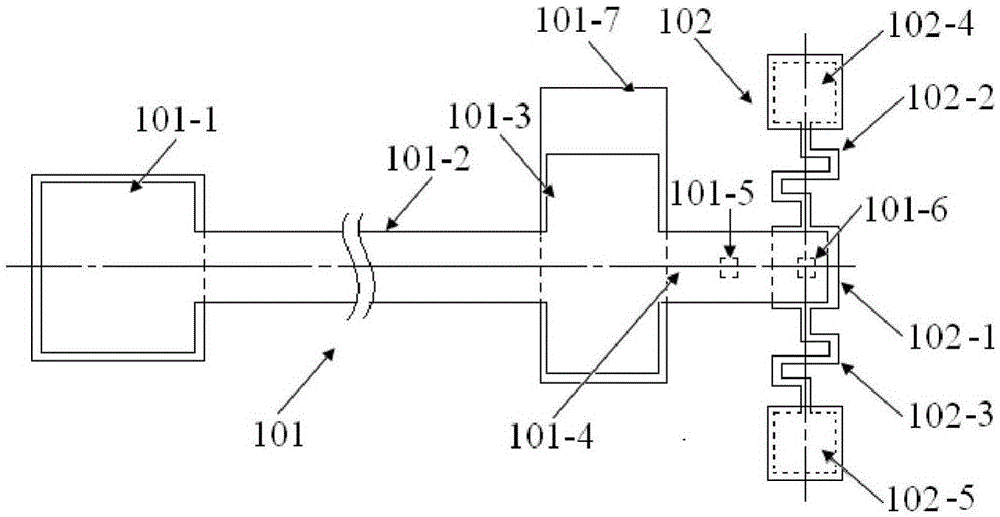

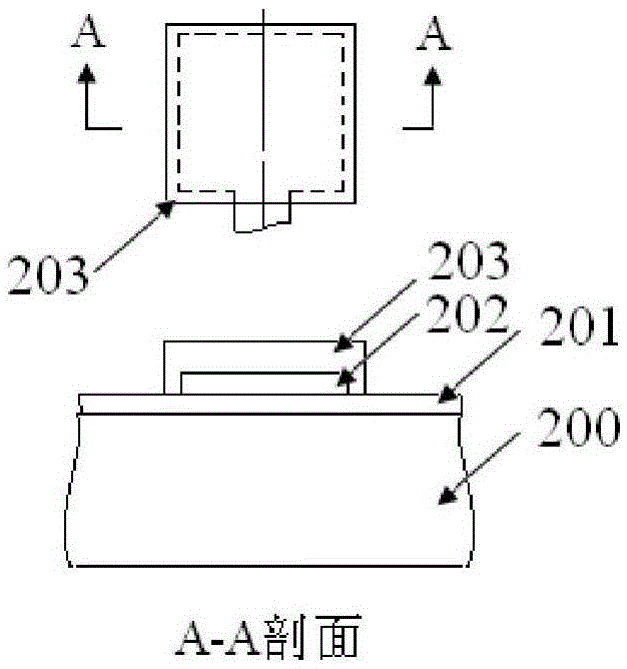

[0031] Attached below figure 1 , figure 2 and image 3 The present invention will be further described.

[0032] The invention provides a test structure for measuring Young's modulus of thin film silicon material on an insulating substrate. The test structure consists of two sets of structures. The first set of structures such as figure 1 As shown, this group of structures consists of a polysilicon cantilever beam 101, a thin-film silicon cantilever beam 103, and a backing plate 102 made of thin-film silicon; the second group is as figure 2 As shown, it consists of a polysilicon cantilever beam 101 and a backing plate 102 made of thin film silicon. The difference between the two groups of structures is whether or not the thin-film silicon cantilever beam 103 is included, and other corresponding unit structures and geometric dimensions in the two groups of structures are identical.

[0033] The polysilicon cantilever beam 101 of the first group of test structures consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com