Connecting piece of battery module

A battery module and connector technology, which is applied to battery pack components, electrical components, circuits, etc., can solve the problems of difficult quality assurance, difficulty in realization, insufficient cross-sectional area of metal plates to provide high-current discharge connecting pieces, safety accidents, etc. , to achieve the effect of low production cost, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

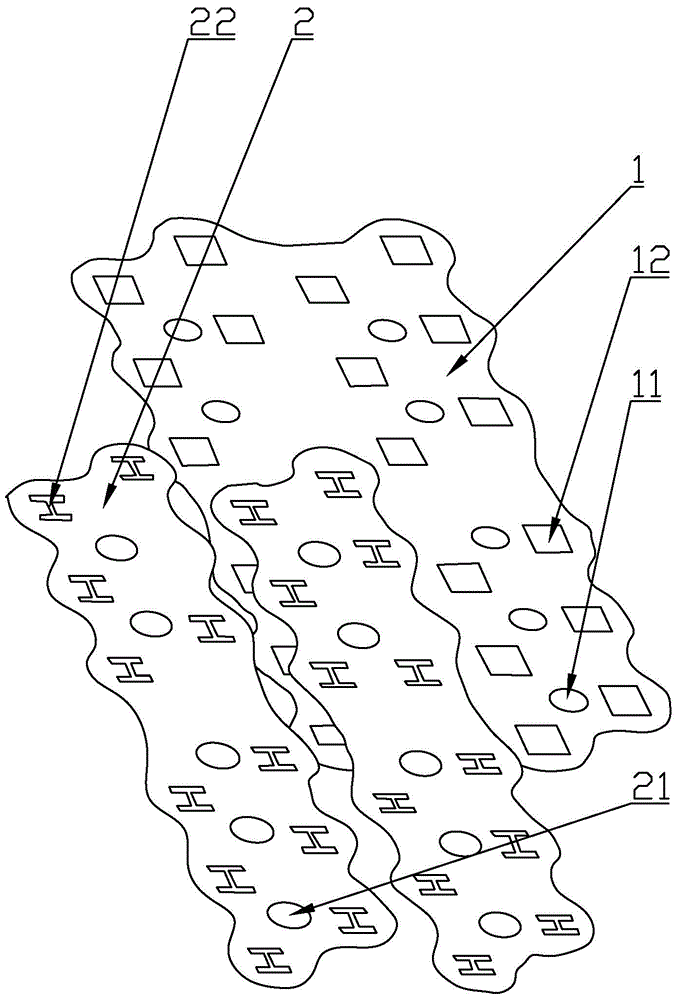

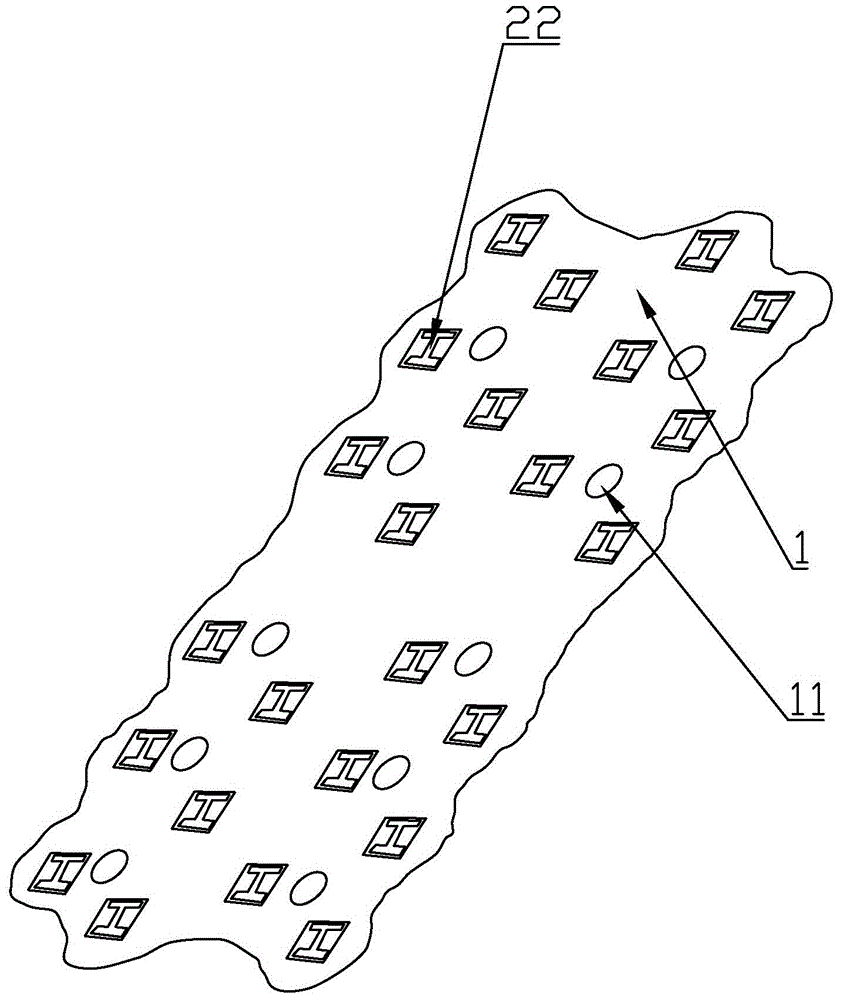

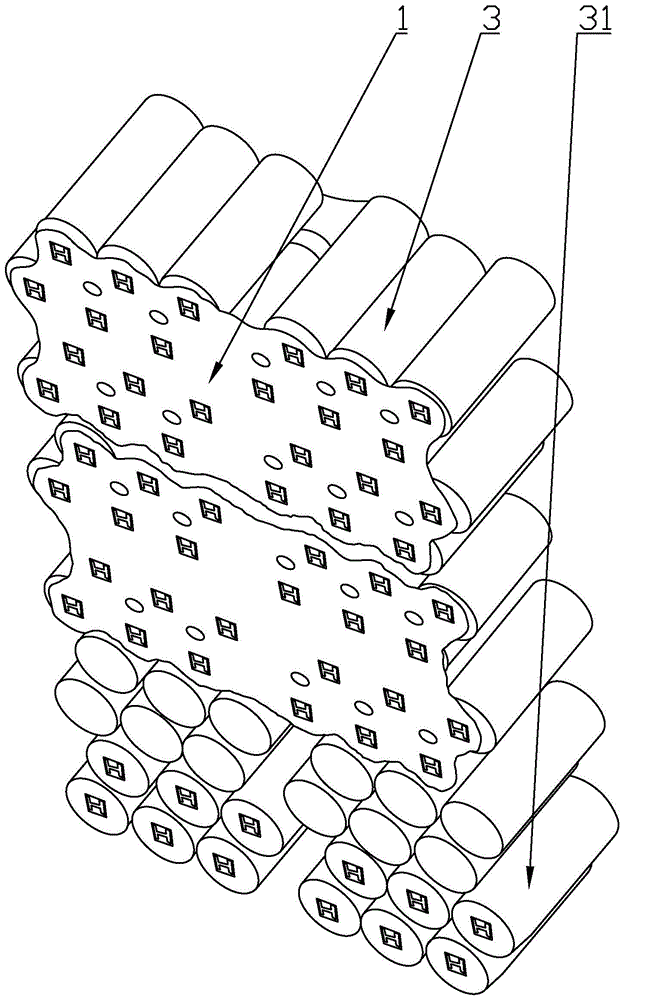

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 with Image 6 As shown, a connector for a battery module includes a first metal plate 1 and a second metal plate 2, the first metal plate 1 is provided with a plurality of through holes, and the second metal plate 2 is provided with a plurality of holes corresponding to the through holes. Corresponding special-shaped through-hole;

[0035] After the through-holes and special-shaped through-holes are aligned accordingly, the first metal plate 1 and the second metal plate 2 are fixedly connected to form a double-layer composite plate; The connector of the double-layer metal plate combined with the second metal plate 2, the first metal plate 1 and the second metal plate 2 carry the input and output of large current at the same time, the special-shaped through hole of the second metal plate 2 and the battery 31 Welding and fixing, connecting multiple battery cells 31 to form a battery module 3, the through-hole of the...

Embodiment 2

[0046] Such as Figure 5 As shown, the rest are the same as in Embodiment 1, the difference is that the shape of the through hole is a U-shaped hole 13, leaving an available space for the welding of the I-shaped hole 22 and the battery core 31, and no special description is made here. The limitations also belong to the protection scope of the present invention. Its structural features and mechanism of action are also the same as those in Example 1, and will not be repeated here.

Embodiment 3

[0048] Such as Figure 7As shown, the rest are the same as in Embodiment 1, the difference is that the shape of the special-shaped through hole is an E-shaped hole 23, which prevents the weld from being welded due to excessive pressure at the welding point, and also belongs to the protection scope of the present invention. Its structural features and mechanism of action are also the same as those in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com