An automatic water supply steam cleaning machine

A technology for automatic water supply and washing machine, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of high heating power, long preheating time, large boiler volume, etc. Small size, short preheating time and small boiler volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

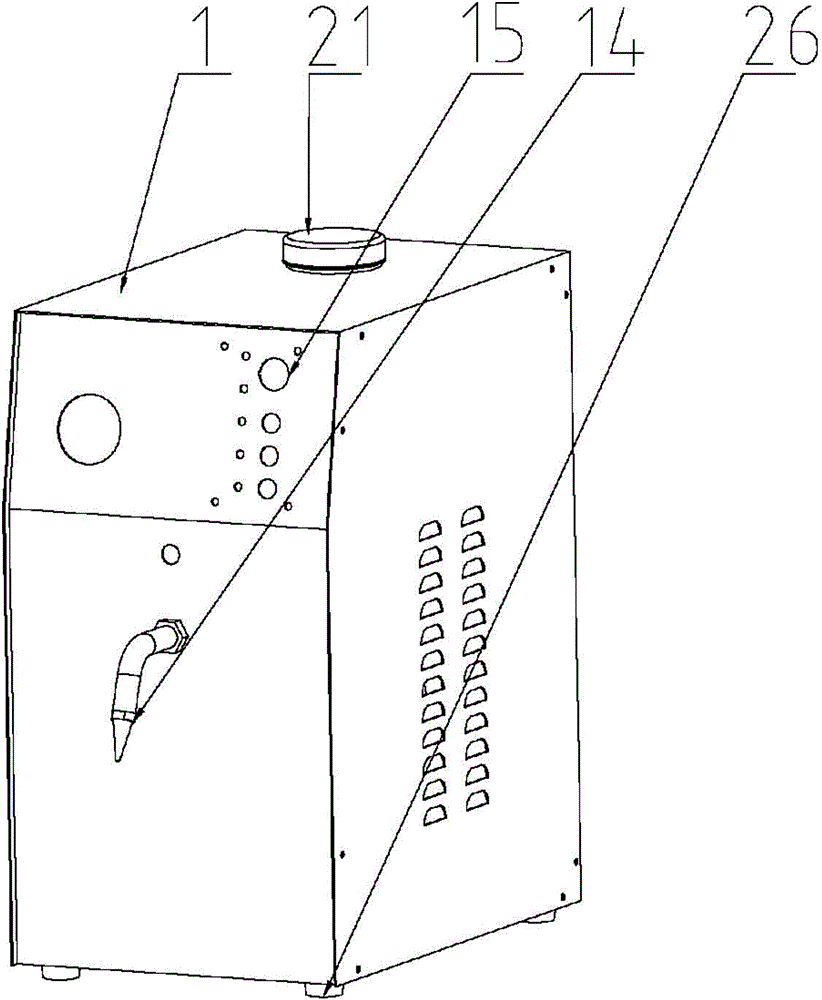

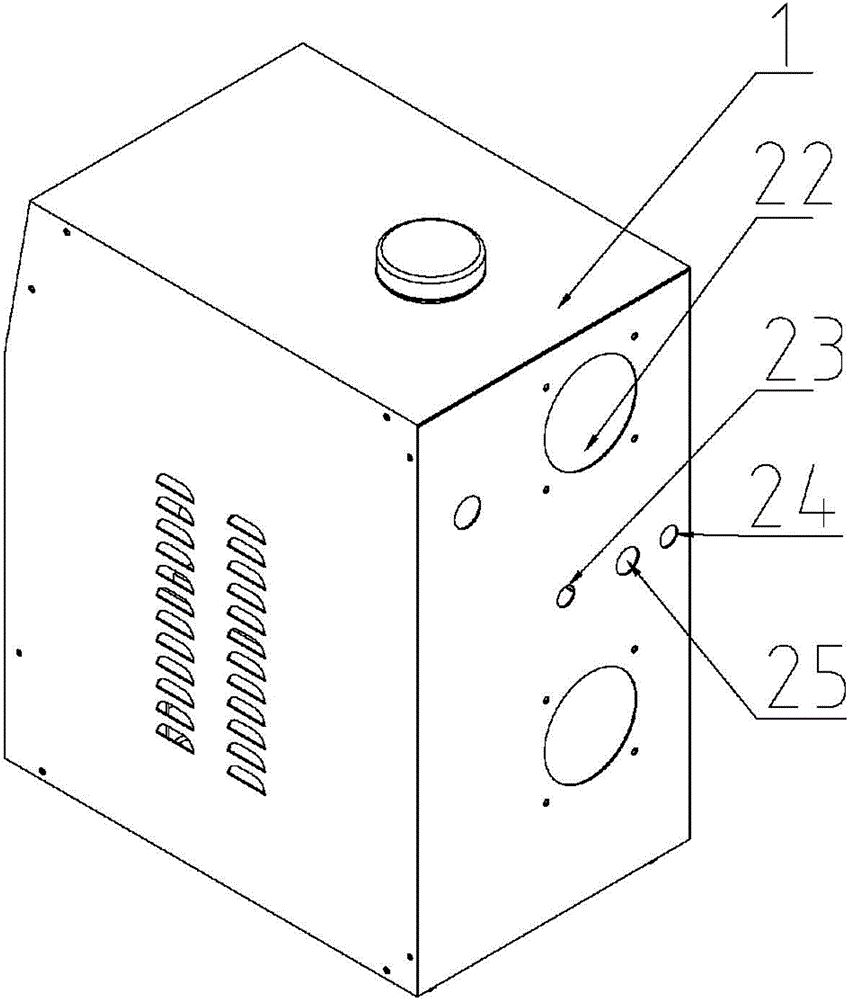

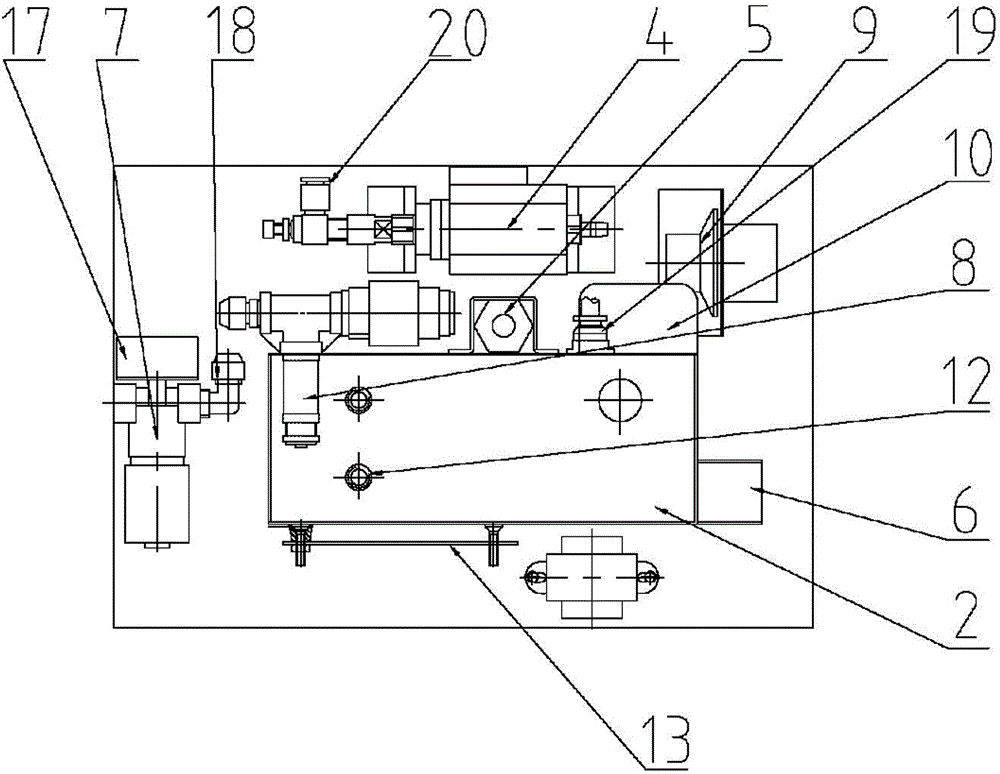

[0019] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is an automatic water supply steam cleaning machine, which consists of a housing 1, a water storage tank 2 contained in the housing 1, an electric heating steam boiler 3, an electromagnetic pump 4, a one-way valve 5, and a water inlet electromagnetic valve 6. Steam solenoid valve 7, safety valve 8, temperature controller 9, pressure controller 10, high temperature electronic water level gauge 11, room temperature electronic water level gauge 12, microcomputer controller 13, steam nozzle 14 and operation panel 15 are assembled and formed .

[0020] Wherein, the water inlet electromagnetic valve 6, the water storage tank 2, the electromagnetic pump 4, the one-way valve 5, the electric heating steam boiler 3, the steam electromagnetic valve 7, and the steam nozzle 14 are connected in sequence. A set of heating tubes 16 are arranged in the electric heating steam boiler 3 . The steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com