Secondary air supply system for internal combustion engine

一种二次空气、供应系统的技术,应用在内燃活塞发动机、燃烧发动机、机械设备等方向,能够解决二次空气流量误差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

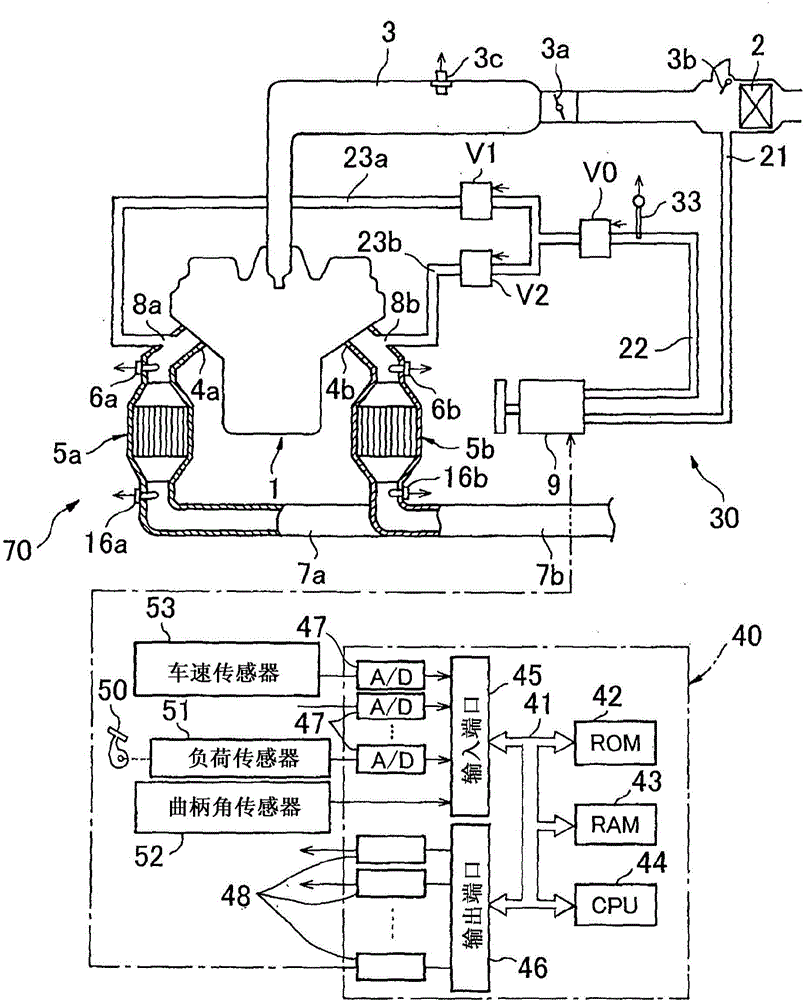

[0036] (first embodiment) will refer to Figure 1 to Figure 9 A secondary air supply system for an internal combustion engine according to a first embodiment is described. In the present exemplary embodiment the internal combustion engine is arranged in a vehicle.

[0037] figure 1 is a schematic view of the internal combustion engine according to the present embodiment. In this embodiment the internal combustion engine is a multi-cylinder V-type gasoline engine. The internal combustion engine in this embodiment includes an engine body 1 , an exhaust gas control system 70 for purifying exhaust gas, and a secondary air supply system 30 . The left and right cylinders of the engine block 1 are respectively coupled to exhaust pipes 7a and 7b via mutually independent exhaust manifolds 4a and 4b. The exhaust gas control system 70 in this embodiment includes catalytic converters 5a and 5b, each of which supports a catalyst having an oxidation function. Catalytic converters 5a an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com