Preparation method of little yellow croaker enzymatic hydrolysis liquid

A technology of small yellow croaker and enzymatic hydrolyzate, which is applied in the field of food additives, can solve the problems of low flavor intensity, high proportion of macromolecular substances, and insufficient natural feeling of fish meat enzymatic hydrolyzate, and achieve mellow taste, high flavor intensity, and overcome the overall flavor lower effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of small yellow croaker enzymatic hydrolyzate, comprising the steps of:

[0016] Put 500g of crushed frozen small yellow croaker, a mixture of 0.4g of compound protease and 0.25g of trypsin in the reactor, stir for 5 minutes, then heat up, the reaction temperature is 55°C for 1 hour, and after the end of the enzymolysis, raise the temperature to 80°C to kill the enzyme After 20 minutes, the temperature was lowered to 40°C after the enzyme inactivation was completed, and it was left to stand at room temperature for 20 minutes, filtered through a 40-mesh sieve to remove the residue, and the filtrate was collected to obtain the small yellow croaker enzymatic hydrolyzate.

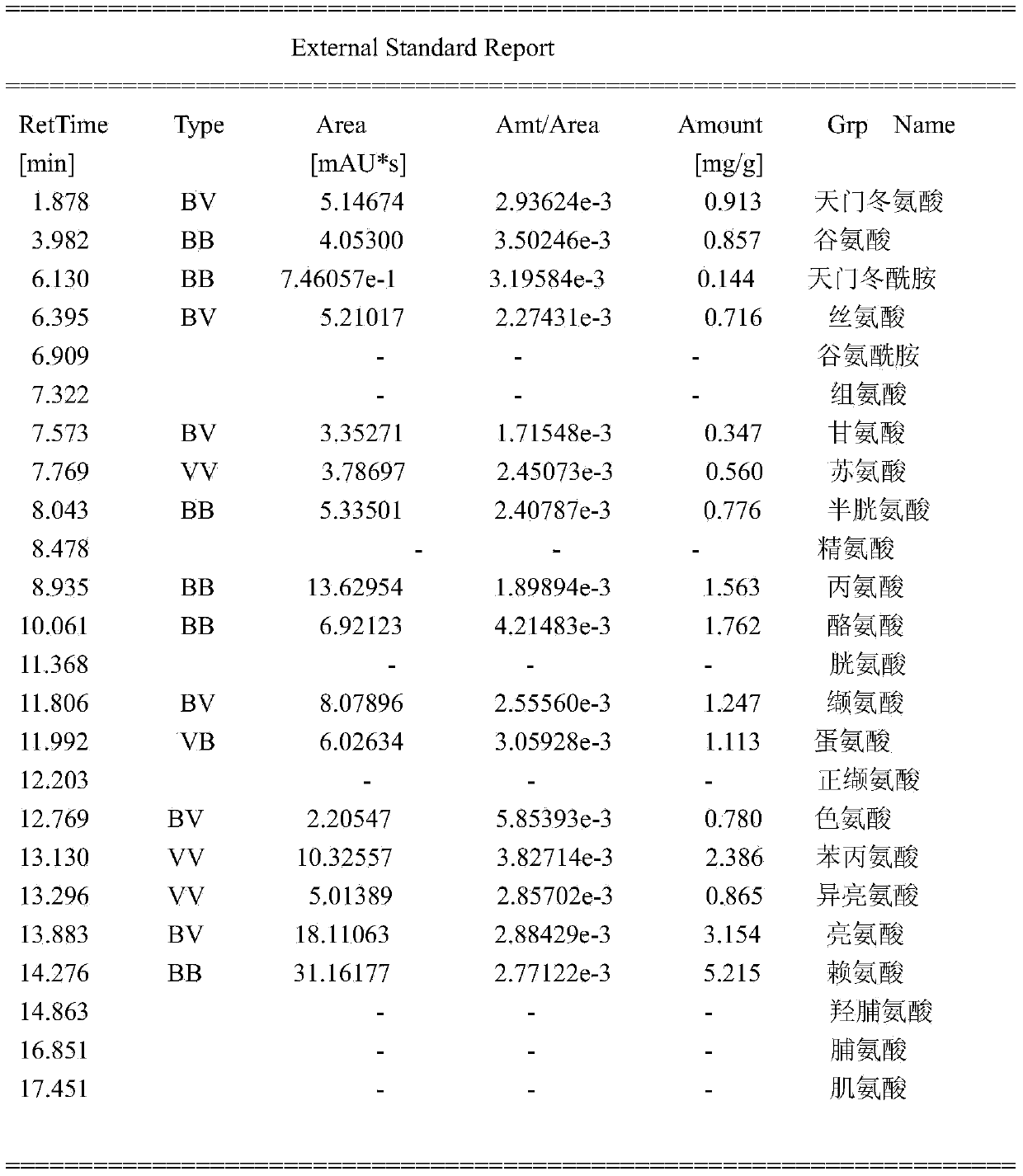

[0017] Amino acid distribution analysis results of enzymatic hydrolysis of small yellow croaker:

[0018]

Embodiment 2

[0020] A preparation method of small yellow croaker enzymatic hydrolyzate, comprising the steps of:

[0021] Put 500g of crushed frozen small yellow croaker, a mixture of 0.5g of compound protease and 0.3g of trypsin in the reactor, stir for 5 minutes, then heat up, the reaction temperature is 60°C for 2 hours, and after the end of the enzymolysis, raise the temperature to 80°C to kill the enzyme After 20 minutes, the temperature was lowered to 40°C after the enzyme inactivation was completed, and it was left to stand at room temperature for 20 minutes, filtered through a 40-mesh sieve to remove the residue, and the filtrate was collected to obtain the small yellow croaker enzymatic hydrolyzate.

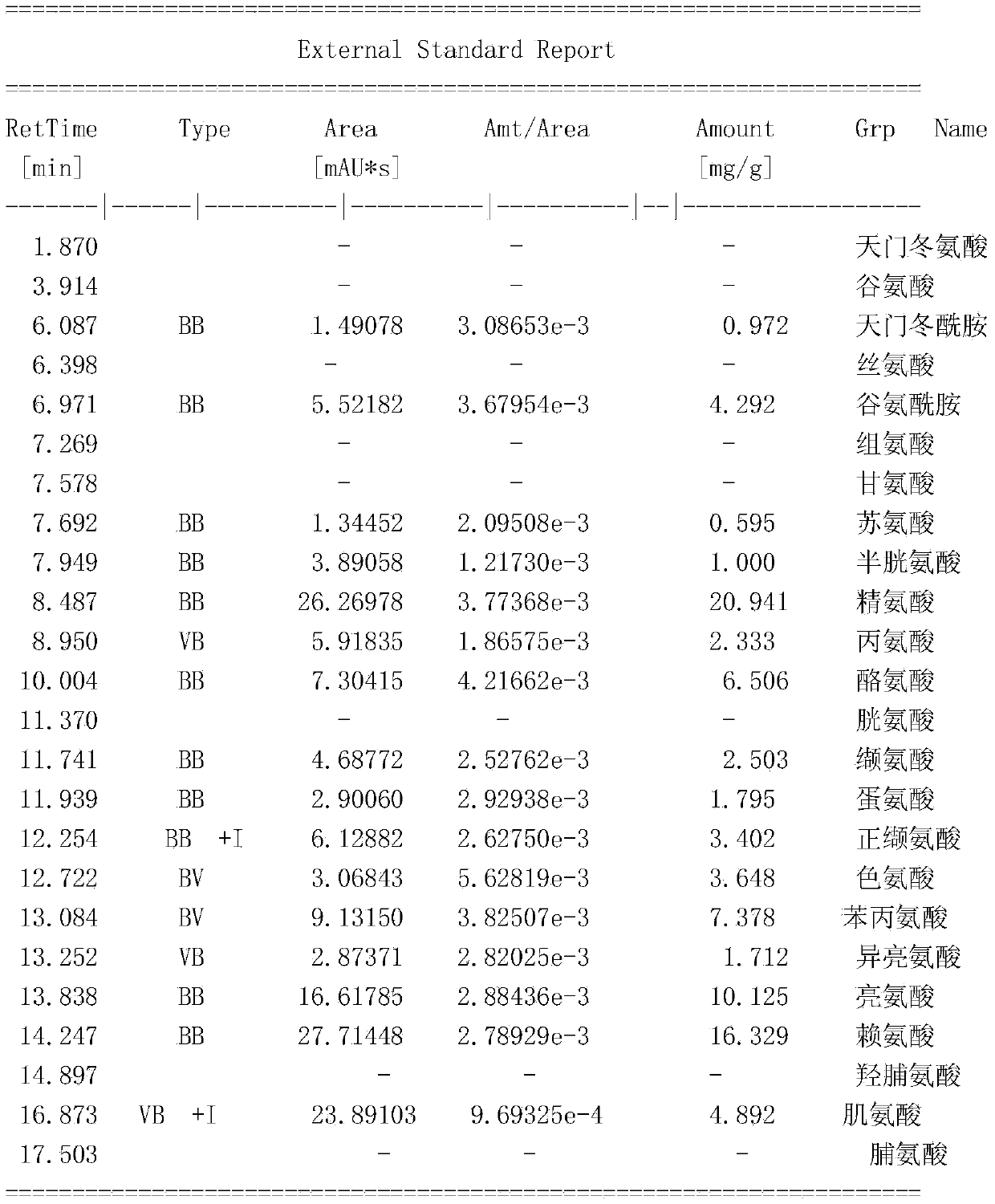

[0022] Amino acid distribution analysis results of enzymatic hydrolysis of small yellow croaker:

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com