Patents

Literature

36results about How to "Increase Flavor Intensity" patented technology

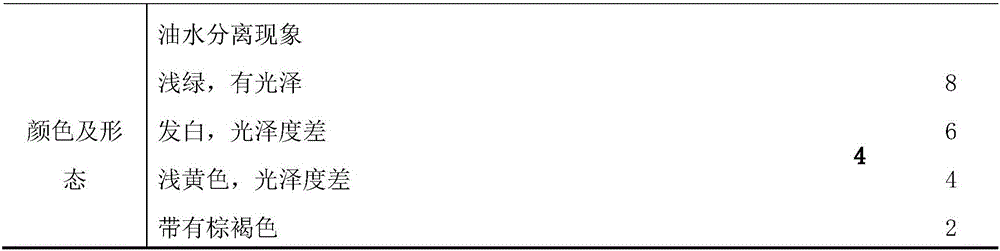

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of flower fragrance type kung fu black tea

InactiveCN106070796AHigh organic contentShort organic contentPre-extraction tea treatmentClimate change adaptationShootBlack tea

The invention discloses a processing method of flower fragrance type kung fu black tea. The method comprises the steps of fresh leaf picking, sun drying, fine manipulation of green tea leaves, quick-freezing withering, unfreezing, rolling, fermentation, first firing, full firing, fragrance increasing, vacuum packaging and the like. The technology is improved for solving the problems that when Lingyun white tea variety black tea is processed, taste is light in freshness and sweetness, fragrance is light and style and variety are monotonous. The processing method comprises the specific steps that tea shoots with two leaves and a bud or with three leaves and a bud of Lingyun white tea trees are picked as raw materials, and technological parameters of sunlight withering, fine manipulation of green tea leaves, freezing withering, rolling, fermentation, full-fire drying, drying and fragrance increasing are enhanced so as to improve a traditional processing method, so that the product has the quality style characteristics that strips are compact and uniform, color and luster are black and smooth, the soup color is orange red and bright, the fragrance is rich and lasting, the taste is mellow and refreshing and leave bottoms are red, bright and uniform, and the black tea has obvious nectar fragrance besides sweet fragrance, and meets requirements of different consumers.

Owner:广西隆林三冲茶业有限公司

Chicken umami peptide and preparation method and application thereof

ActiveCN105707405AHigh flavor intensityIncreased umami intensityFood ingredient as taste affecting agentFood extractionPeptideChemistry

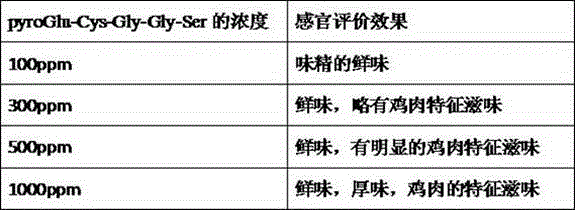

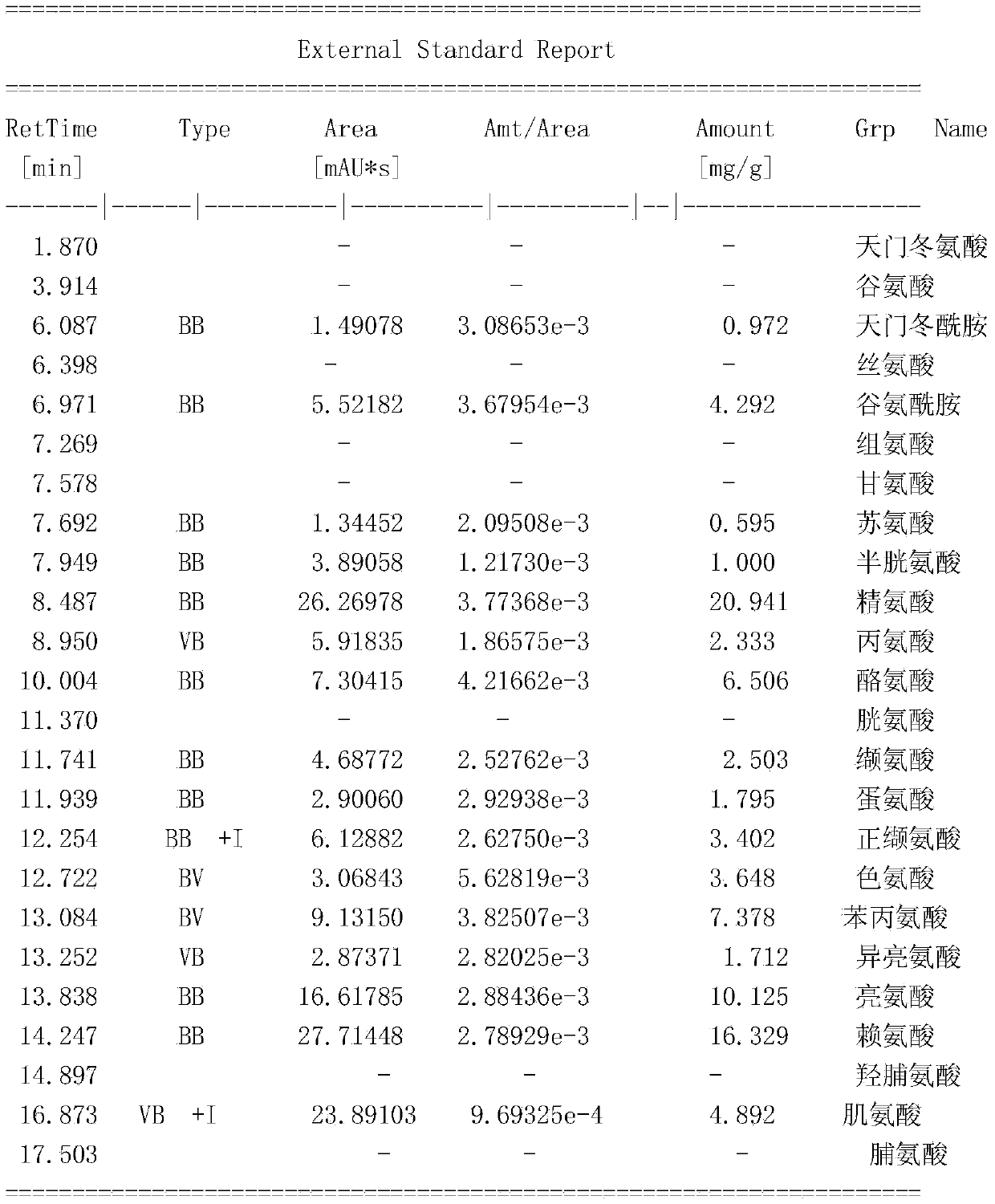

The invention discloses a chicken umami peptide and a preparation method and application thereof. The preparation method comprises the steps that chicken chest meat is taken as a raw material to be subjected to multi-enzymatic hydrolysis to obtain chicken protein enzymatic hydrolysate; the chicken protein enzymatic hydrolysate is separated and purified to obtain the novel flavor peptide, and the amino acid sequence of the peptide is pyroGlu-Cys-Gly-Gly-Ser. The chicken umami peptide has the better flavor intensity, can significantly improve the thick taste and umami of food under the concentration of 300 ppm and can be widely applied to the fields of food, seasonings and the like.

Owner:GUANGDONG CHUBANG FOOD

Preparation method of enzyme-hydrolyzed butter with high flavor intensity and use thereof in essence with milk flavor

InactiveCN102178199ASignificant flavor enhancementEnzyme hydrolysis time is shortAnimal feeding stuffAccessory food factorsAlcoholFlavoring essences

The invention discloses a preparation method of enzyme-hydrolyzed butter with a high flavor intensity and use thereof in essence with a milk flavor. In the method, a neutral system prepared by mixing butter and water is used as a screening module, and one or a mixture of several of a group of screened lipases is subjected to enzymolysis reaction to form a group of corresponding enzyme-hydrolyzed butter products; the group of products are treated by an acid value and gas value combined analysis method under the same process conditions to determine the flavor materials of the enzyme-hydrolyzed butter; and the final preparation method is determined when final products of the same acid value and flavor components under the same process. In the invention, the flavor intensity of the enzyme-hydrolyzed butter is improved by screening and evaluating lipase and controlling an enzymolysis process. The final products can be used as raw materials for preparing the milk-flavor essence with improved mellow taste and long-lasting fragrance and can be applied to baked products.

Owner:TIANNING FLAVOR JIANGSU

Chicken flavor essence and its preparation method

The invention relates to a chicken flavor essence and its preparation method. the essence is prepared from the following raw materials of: by weight, 10-50 parts of a Tenebrio molitor larva enzymatic hydrolysate, 2-6 parts of amino acid, 4-10 parts of reducing sugar, 40-70 parts of a chicken enzymatic hydrolysate, 0-8 parts of refined chicken oil, 0-2 parts of a yeast extract, 0-2 parts of HVP, 0-1 part of VB1, 0-1 part of I+G, 0-2 parts of onion puree and 0-2 parts of ginger puree, wherein the Tenebrio molitor larva enzymatic hydrolysate is prepared by enzymatic hydrolysis of Tenebrio molitor larva by the use of protease; and the chicken enzymatic hydrolysate is prepared by enzymatic hydrolysis of chicken by the use of protease. As the Tenebrio molitor larva enzymatic hydrolysate is adpoted in the invention and Tenebrio molitor larva has higher protein content than chicken at source, the enzymatic hydrolysate thereof contains high contents of amino acid and peptide and the cost is low as well. The enzymatic hydrolysate is applied in thermal response so as to generate more flavor compounds, thus raising flavor intensity of the meat flavor essence.

Owner:天津味沁百家科技发展有限公司

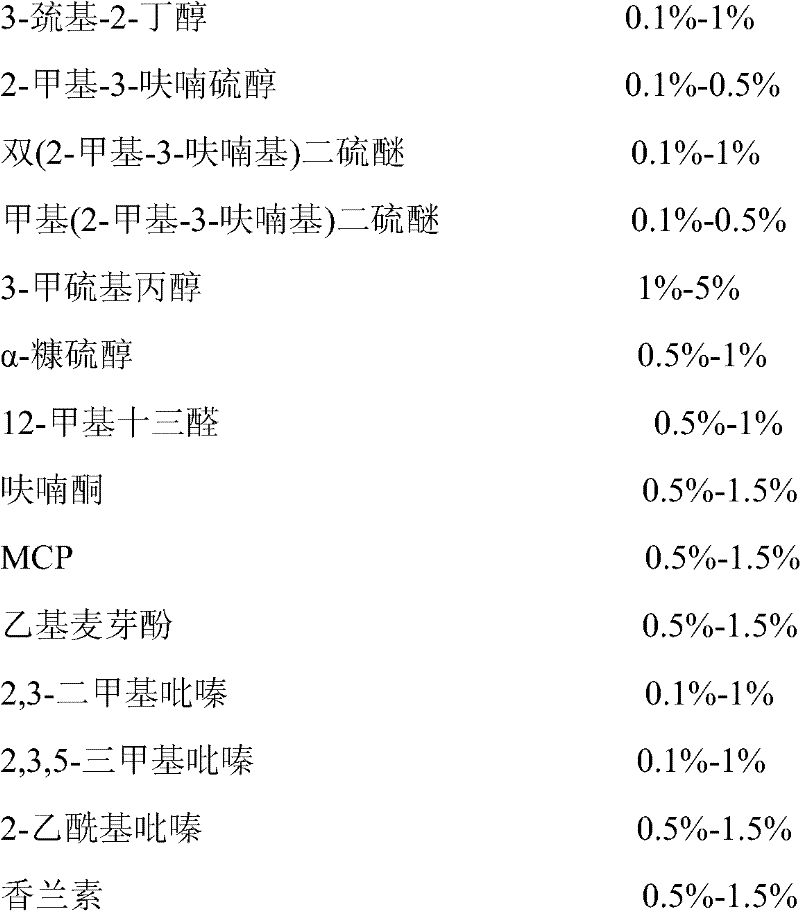

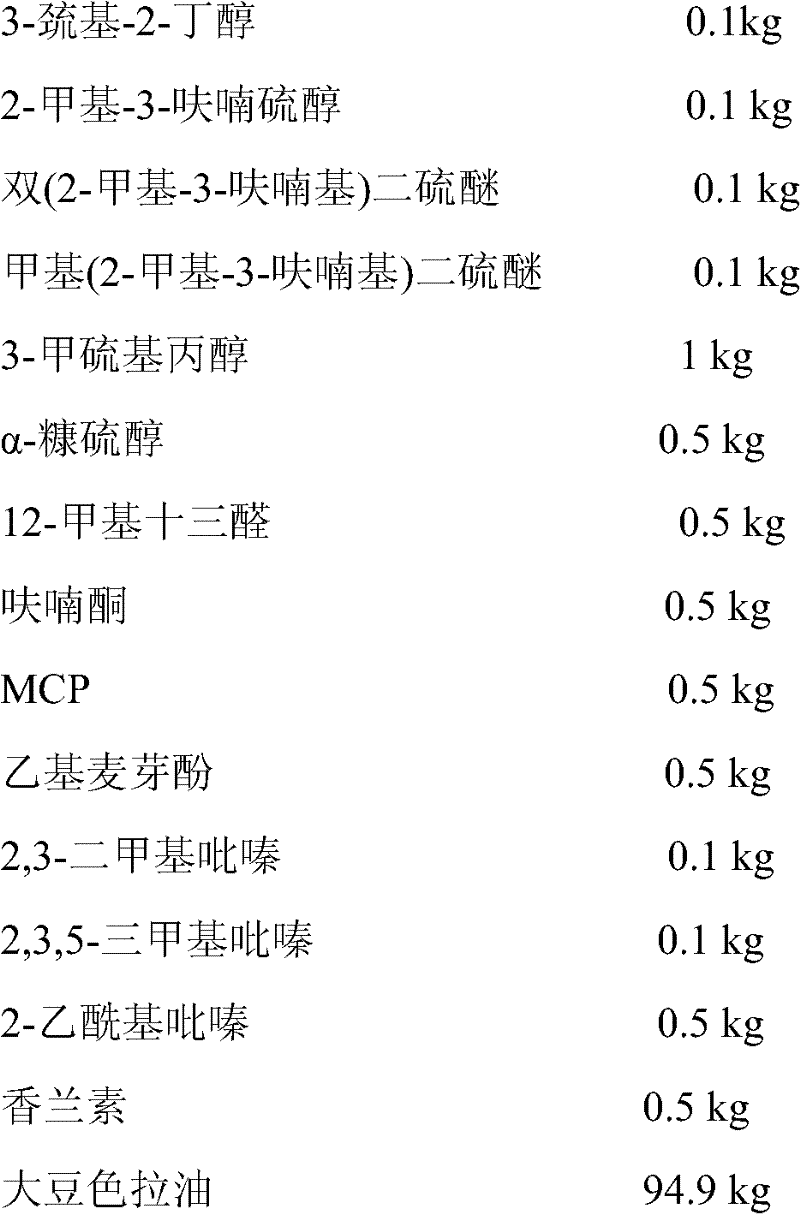

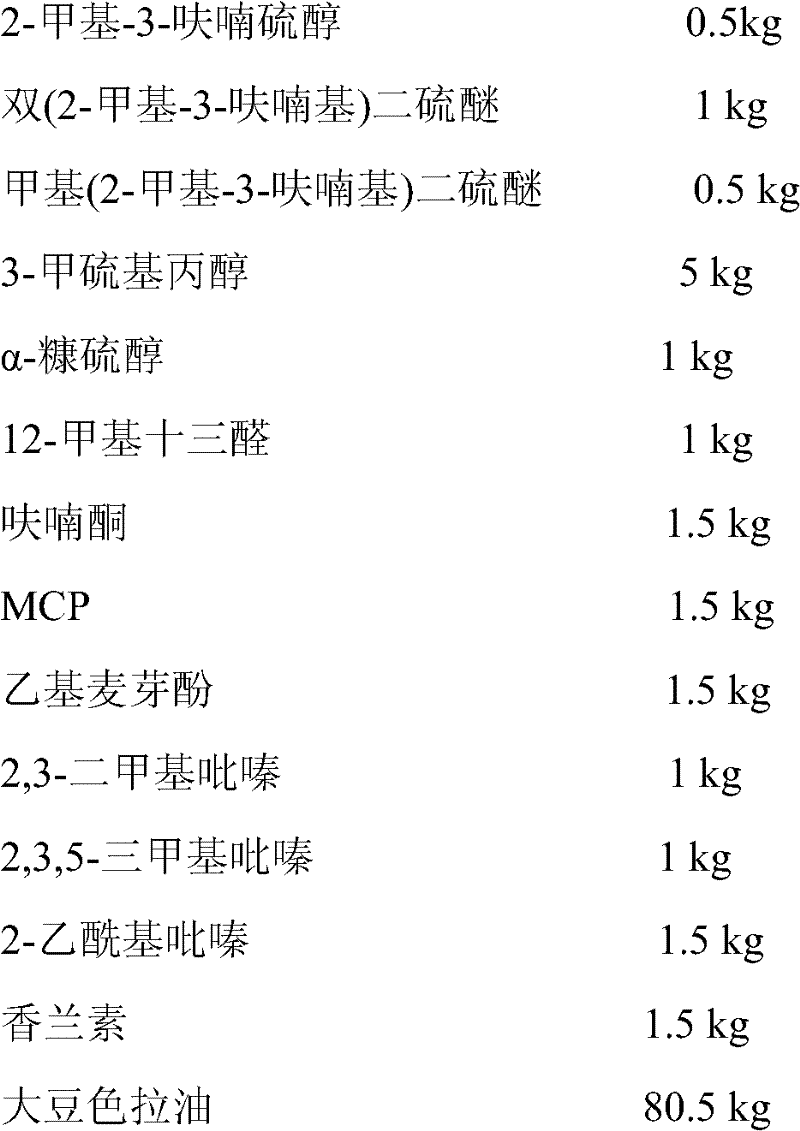

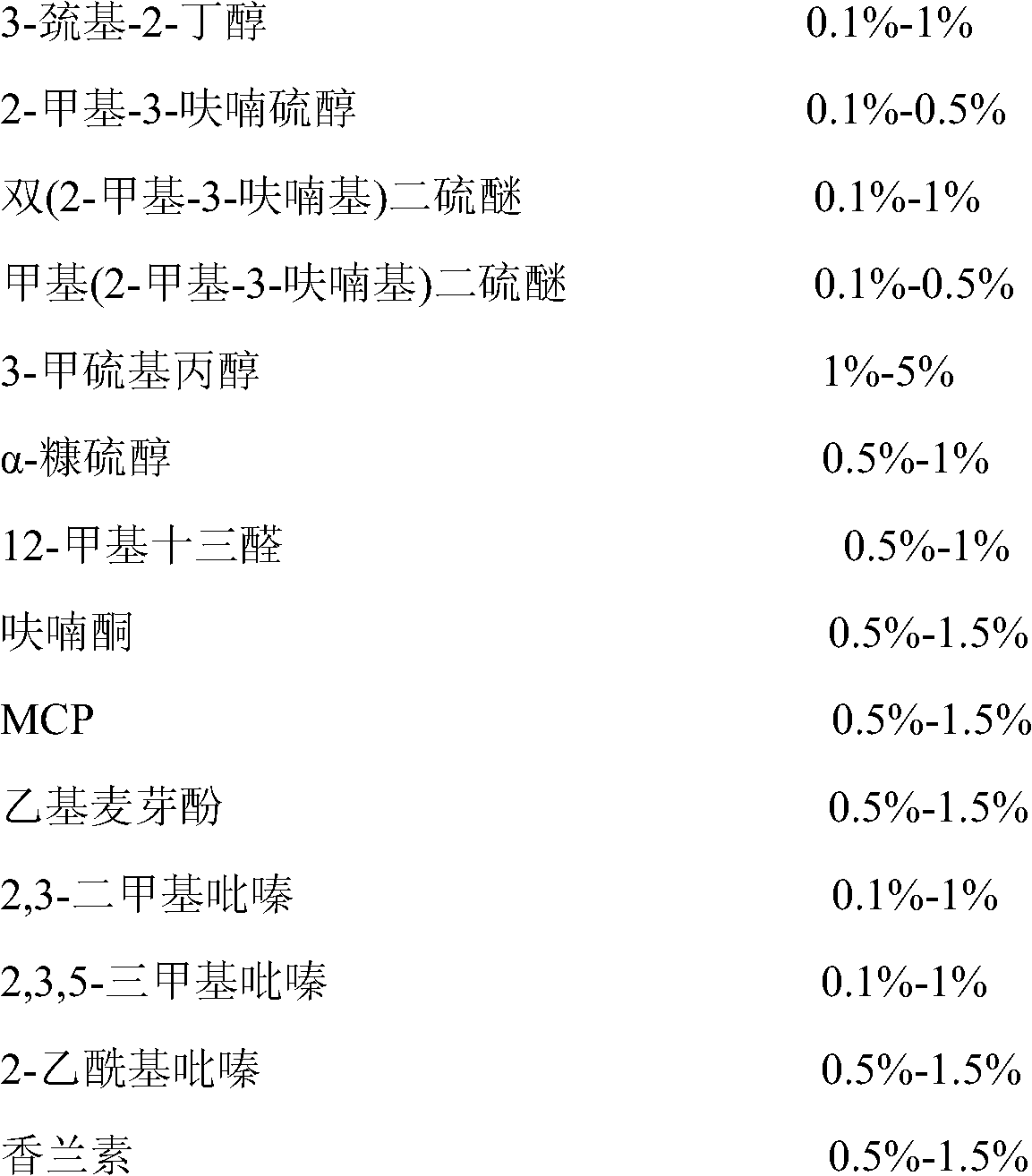

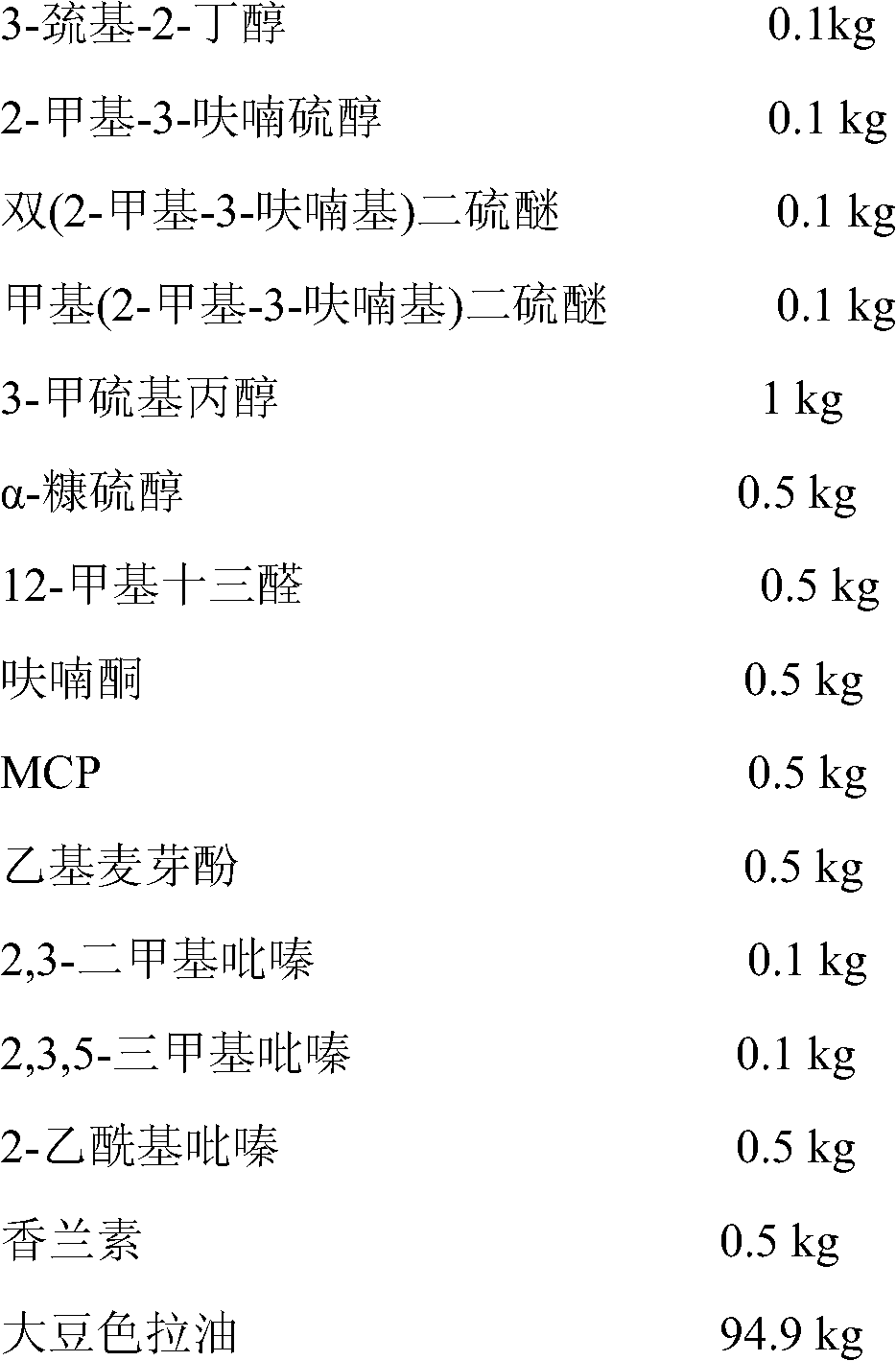

Beef oily essence and preparation method thereof

The invention relates to beef oily essence and a preparation method thereof. The essence is prepared from the following raw materials: 3-sulfydryl-2-butanol, 2-methyl-3-furanthiol, bis(2-methyl-3-furyl) disulfide, methyl(2-methyl-3-furyl) disulfide, 3-methylmercapto-propyl alcohol, alpha-furfurylmercaptan, 12-methyl tridecylic aldehyde, furanone, methylcyclopentadienyl pregnenolone (MCP), ethyl maltol, 2,3-dimethylpyrazine, 2,3,5-trimethylpyrazine, 2-acetyl pyrazine, vanillin and soybean salad oil. The invention also provides a preparation method for the essence. In an essence product prepared by the method, flavor volatile substances contained in roast beef are adopted, and a formula is formulated in a reasonable ratio, so the beef oil essence has the flavor of natural roast beef, vivid and natural fragrance, long fragrance retention and high heat stability. The beef oily essence has an irreplaceable effect in fields of seasonings and instant noodles.

Owner:TIANJIN CHUNFA BIO TECH GRP

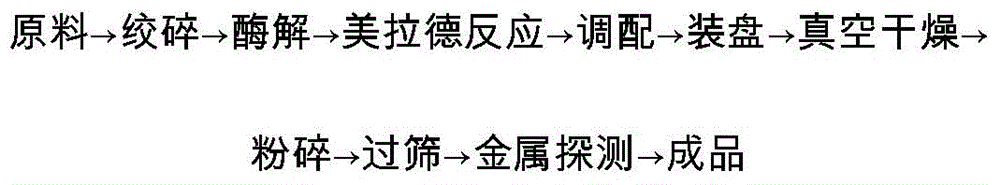

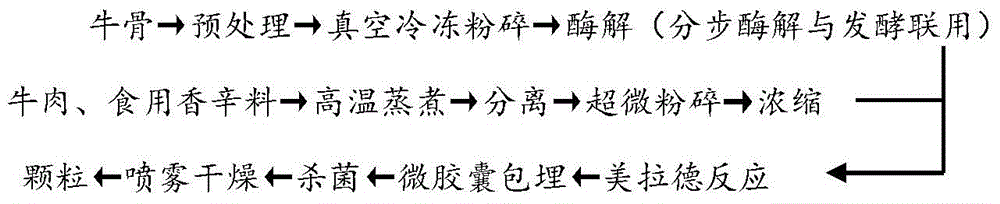

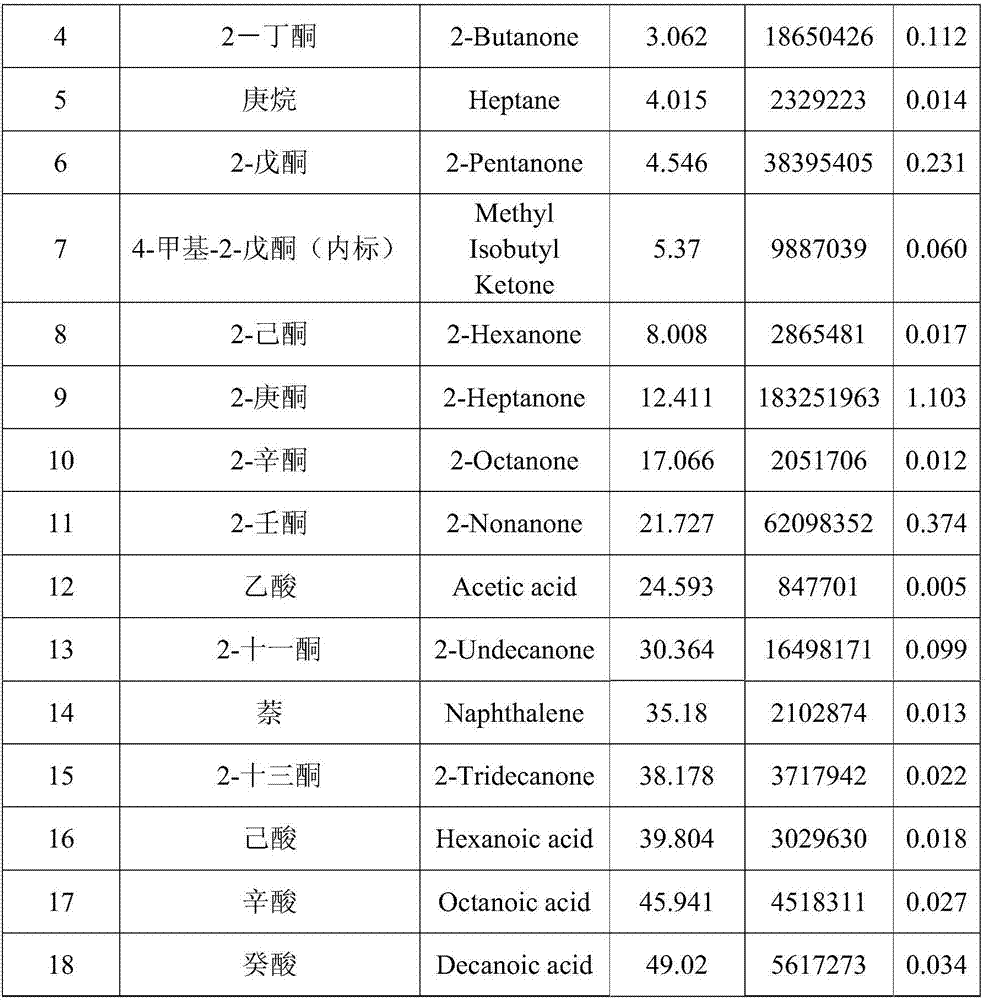

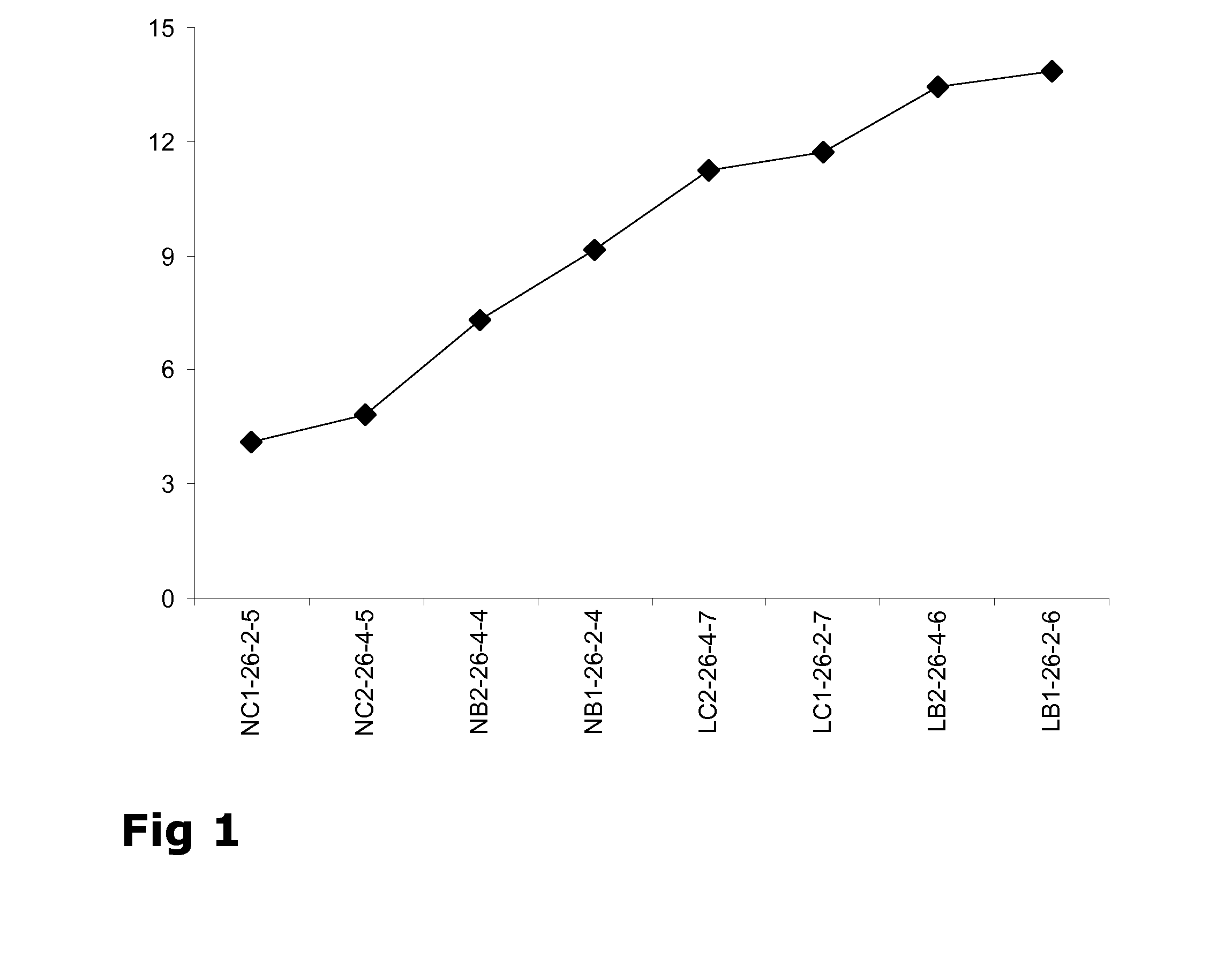

Ultraviolet flavouring method in air curing maturation of pickled and salted poultry product

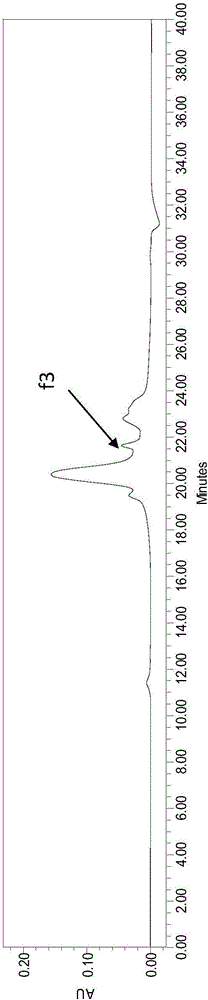

ActiveCN101433341AHigh speedIncrease Flavor IntensityFood preparationMeat/fish preservation by irradiation/electric treatmentPeak areaChemistry

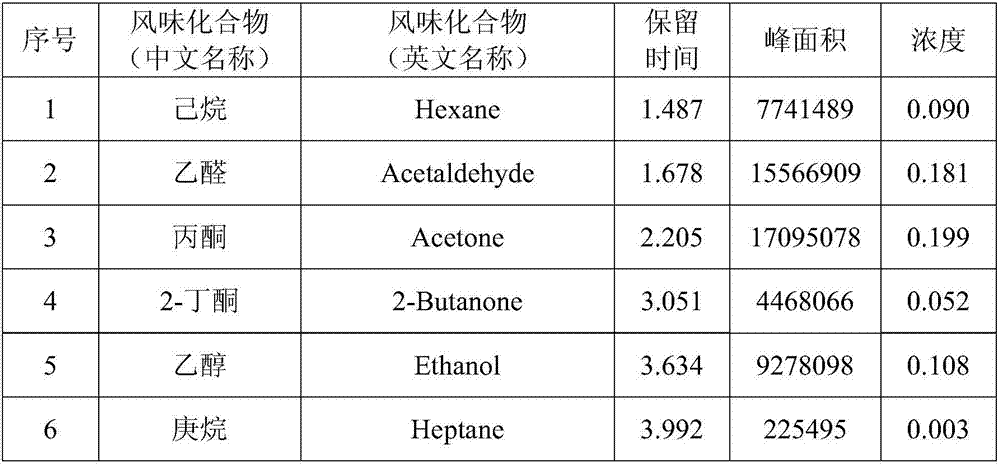

The invention relates to an ultraviolet flavoring method during air drying and cooking of salted and preserved poultry meat products, which belongs to the field of food processing. The method comprises the following steps of killing and treatment of poultry meat, preserving, ultraviolet flavoring (the power of an ultraviolet lighting tube is 30 watts, the wavelength of the ultraviolet lighting tube is 253.7 nanometers, the radiation intensity of the ultraviolet lighting tube is between 90 and 110 mu W / cm<2>, the distance between the poultry meat and the lighting tube is between 1.5 and 1.8 meters, the ambient humidity is between 10 and 13 DEG C, and the irradiation time is between 2 and 3 hours), and cooking after temperature control, humidity control, wind speed control and air drying. By applying GC / MS to analyze the flavor and the compositions of the product, compared with the prior common technical product, the total peak area of flavoring substances after ultraviolet flavoring is increased by more than 20 percent; and the evaluating result of sensory organs also shows that the product after being subjected to ultraviolet flavoring has greatly improved preserved smell and superior flavor. The technology for producing the salted and preserved poultry meat products provided by the method has low production cost, good flavor of the products and simplified technique, and is suitable for industrial production.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

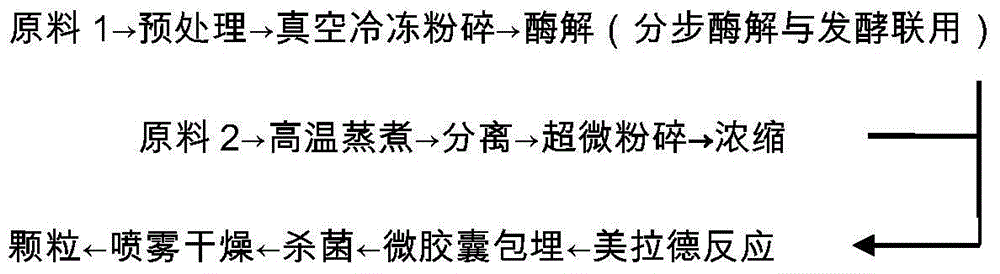

Preparation method of composite beef seasoning

InactiveCN104824612AIncreased soluble calcium contentImprove bioavailabilityFood preparationMaillard reactionCyclodextrin

The invention discloses a preparation method of a composite beef seasoning, which comprises the steps of: (1) treatment of raw materials: cleaning, blanching and soaking fresh cattle bone and beef, removing the dirt on the surface and draining the treated cattle bone and beef, and dicing the cattle bone and beef for later use; (2) performing enzymolysis and fermentation to the cattle bone to obtain a fermentation liquid; (3) preparing beef concentrate; (4) thermal-reaction and granulation: uniformly mixing the fermentation liquid, the beef concentrate and beef ultra-micro powder with addition of cysteine and xylose, and performing a Maillard reaction at 50-60 DEG C for 40-45 min; (5) adding [beta]-cyclodextrin after the reaction finished for flavoring the reaction product and embedding nutrients in the reaction product to enable the ratio of a wall material to a core material to be 1:1-1.5:1; and (6) spray-drying the product to obtain the composite beef seasoning. By means of the method, the content of soluble calcium in the composite beef seasoning is increased and the bioavailability of the soluble calcium is improved. The nutrients in the composite beef seasoning are effectively maintained and the flavor of the seasoning is enhanced.

Owner:LANXI BAIXIANYUAN CONDIMENT CO LTD

Preparation method of microcapsule type fermented cream flavored powder

InactiveCN106954679ADelicate tasteStrong fragranceCream preparationMicroorganismLactic acid bacterium

The invention discloses a preparation method of microcapsule type fermented cream flavored powder through combination of a microorganism fermentation technique and a food microcapsule technique. According to the fermented cream flavored powder, cream is used as a main raw material, different auxiliary substrates are added, fermentation is performed through lactic acid bacterium mixed strains, fermented cream reaching to a fermented end point is embedded with embedding materials and is emulsified, then spray drying is performed, and microencapsulation is performed, so that the microcapsule type fermented cream flavored powder is prepared. The microcapsule type fermented cream flavored powder prepared by the preparation method is rich in fragrance and fine and smooth in mouth feel, has favorable fragrance retention and favorable flavor stability, is suitable for development of foods including beverages, dairy products, ice creams, candies and the like, is wide in application range, and has broad market prospects and high economic values.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Preparation method of strong-flavor peptide in consomme soy sauce and application of flavor thickening peptide

InactiveCN105132496AIncrease Flavor IntensityImprove savoryFermentationFood preparationUltrafiltrationPeptide

The invention discloses a preparation method of flavor thickening peptide in consomme soy sauce and application of the strong-flavor peptide. The preparation method includes: using wheat flour as a raw material; obtaining consomme soy sauce through the steps of starter making, fermentation, adding of glutaminase, fermentation, treatment and the like; enabling the consomme soy sauce to pass an ultrafiltration membrane of 5000 Da in molecule weight; taking permeate; separating and purifying the permeate to obtain a novel flavor thickening peptide product. An amino acid sequence of the flavor thickening peptide is Glu-Gln-Gln-Pro-Glu. The flavor thickening peptide has high flavor development strength, and can remarkably thicken flavor of food when being applied to the food at concentration of 300ppm, thereby being widely suitable for the field of food and condiments.

Owner:JIANGSU SUMEI FOOD

Fish scale protein enzymolysis liquid and preparation method thereof

ActiveCN102613383AStrong aromaMellow tasteAnimal proteins working-upFood preparationHydrolysisOligopeptide

The invention relates to a fish scale protein enzymolysis liquid and a preparation method thereof. The fish scale protein enzymolysis liquid is prepared from the raw materials as follows: fish scales, protease and distilled water, wherein ratio by weight part of the fish scales to the distilled water is (70-90): (10-30); the additive amount of the protease is 0.05-0.2% of the total weight of the fish scales and the distilled water. According to the invention, protease is adopted to hydrolyze the fish scales to obtain amino acids and oligopeptides at higher proportional contents, so that the disadvantages of low hydrolysis rate and low content of micromolecule substances when bright flesh is used as proteolysis are overcome. The fish scale protein enzymolysis liquid has aromatic flavor and mellow mouth feeling, improves flavor intensity of the fish scale protein enzymolysis liquid and lays a good raw material foundation for the protein enzymolysis liquid which is applied to essence in the later period.

Owner:TIANJIN CHUNYU FOOD INGREDIENTS

Preparation method for high rich flavor chicken powder, and application

ActiveCN111642728AIncrease Flavor IntensityIncrease umamiClimate change adaptationFood scienceFood additiveAspergillus oryzae

The invention discloses a preparation method for a high rich flavor chicken powder, and application, and belongs to the biotechnology field of food. The preparation method comprises the following steps of: (1) adding aspergillus oryzae and aspergillus niger spores into chicken to carry out fermentation, and carrying out inactivation after the hydrolysis degree of chicken protein is 30-50% to obtain chicken fermentation liquor; (2) preparing the chicken fermentation liquor obtained in (1) to prepare chicken protein peptide powders; (3) mixing the chicken protein peptide powders obtained in (2)with lactic acid, and heating to obtain a reactant; and (4) regulating the pH value of the reactant obtained in (3) to obtain the high rich flavor chicken powder. According to the preparation method,the high rich flavor chicken powder can be prepared without adding various food additives, meanwhile, the product has strong rich flavors and is high in flavor representation strength, and a delicateflavor and a rich flavor can be obviously improved if the high rich flavor chicken powder is applied to food.

Owner:广东百味佳味业科技股份有限公司

Meaty reaction essence prepared by using enzymatic hydrolysate for larvae of barley pests

ActiveCN102697019AHigh in proteinRaise the ratio contentFood preparationVegetable ProteinsYeast extract

The invention relates to a meaty reaction essence prepared by using an enzymatic hydrolysate for larvae of barley pests. The essence is prepared from the following raw materials in part by weight: 10-50 parts of enzymatic hydrolysate for larvae of barley pests, 2-6 parts of amino acid, 4-10 parts of reducing sugar, 40-70 parts of enzymatic hydrolysate for meat, 0-8 parts of fat, 0-2 parts of yeast extract, 0-2 parts of HVP (Hydrolyzed Vegetable Protein), 0-1 part of VB1, 0-1 part of I plus G, and 0-5 parts of spice. The enzymatic hydrolysate for larvae of barley pests is prepared from larvae of barley pests, proteolytic enzyme and distilled water, wherein the weight part ratio of the larvae of barley pests to the distilled water is (70-90):(10-30), and the added content of the proteolytic enzyme accounts for 0.05-0.2% of the total weight of the larvae of barley pests and distilled water. The formula of the essence, provided by the invention, uses the enzymatic hydrolysate for larvae of barley pests for promoting thermal reaction, so that odor intensity of the essence is improved.

Owner:TIANJIN CHUNFA BIO TECH GRP

Ultraviolet flavouring method in air curing maturation of pickled and salted poultry product

ActiveCN101433341BHigh speedIncrease Flavor IntensityFood preparationMeat/fish preservation by irradiation/electric treatmentAdditive ingredientUltraviolet

The invention relates to an ultraviolet flavoring method during air drying and cooking of salted and preserved poultry meat products, which belongs to the field of food processing. The method comprises the following steps of killing and treatment of poultry meat, preserving, ultraviolet flavoring (the power of an ultraviolet lighting tube is 30 watts, the wavelength of the ultraviolet lighting tube is 253.7 nanometers, the radiation intensity of the ultraviolet lighting tube is between 90 and 110 mu W / cm<2>, the distance between the poultry meat and the lighting tube is between 1.5 and 1.8 meters, the ambient humidity is between 10 and 13 DEG C, and the irradiation time is between 2 and 3 hours), and cooking after temperature control, humidity control, wind speed control and air drying. By applying GC / MS to analyze the flavor and the compositions of the product, compared with the prior common technical product, the total peak area of flavoring substances after ultraviolet flavoring isincreased by more than 20 percent; and the evaluating result of sensory organs also shows that the product after being subjected to ultraviolet flavoring has greatly improved preserved smell and superior flavor. The technology for producing the salted and preserved poultry meat products provided by the method has low production cost, good flavor of the products and simplified technique, and is suitable for industrial production.

Owner:JIANGSU ACAD OF AGRI SCI

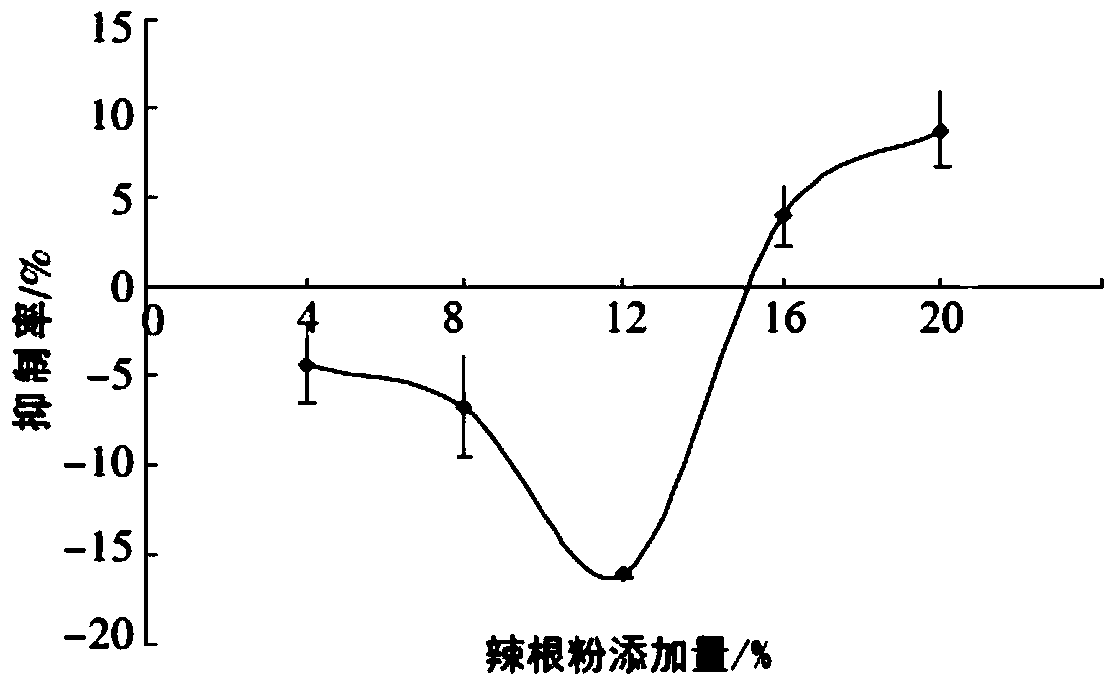

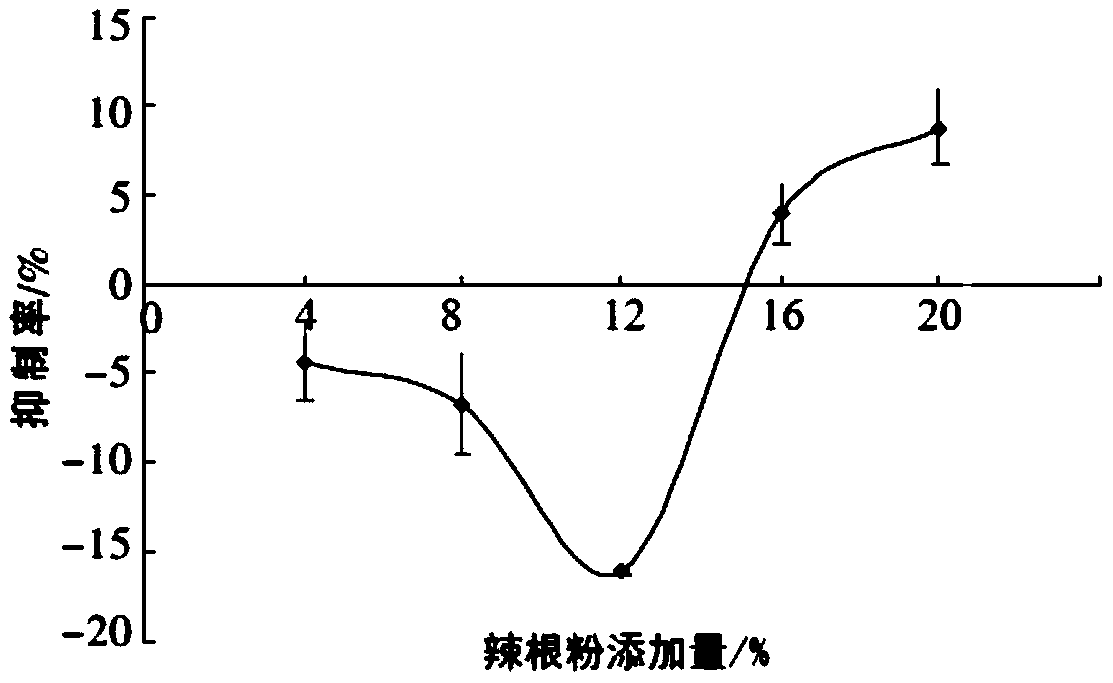

Method for regulating and controlling quality of horseradish sauce by fermentation

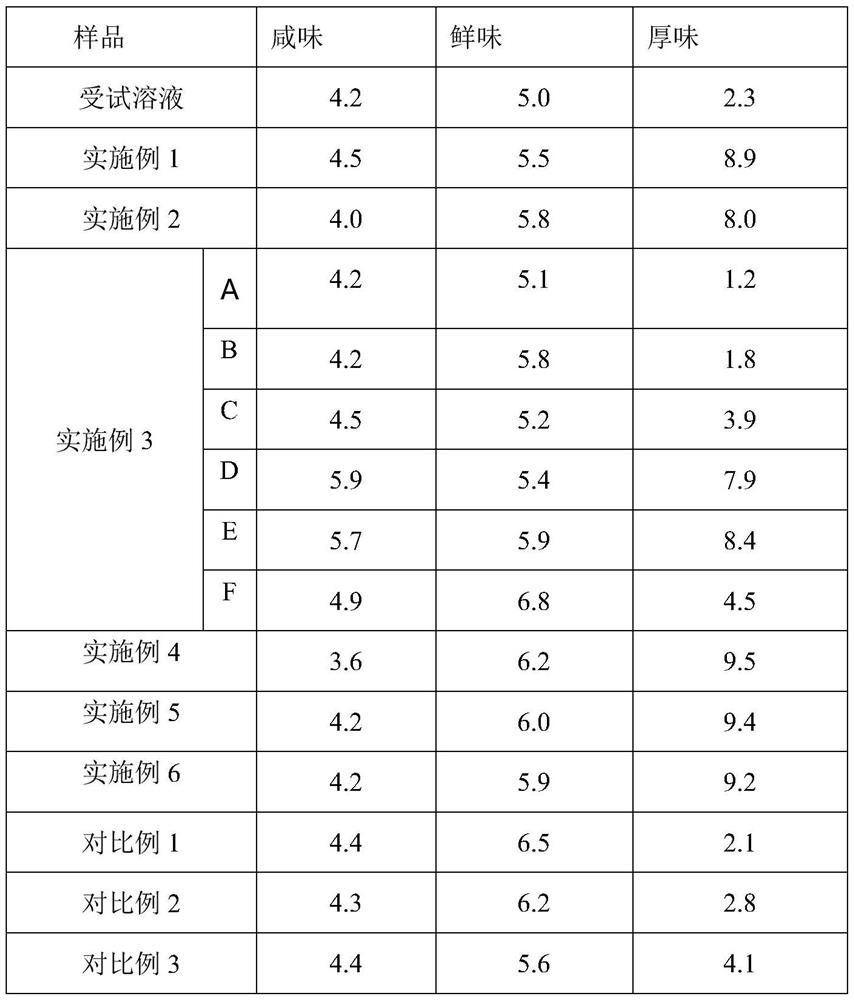

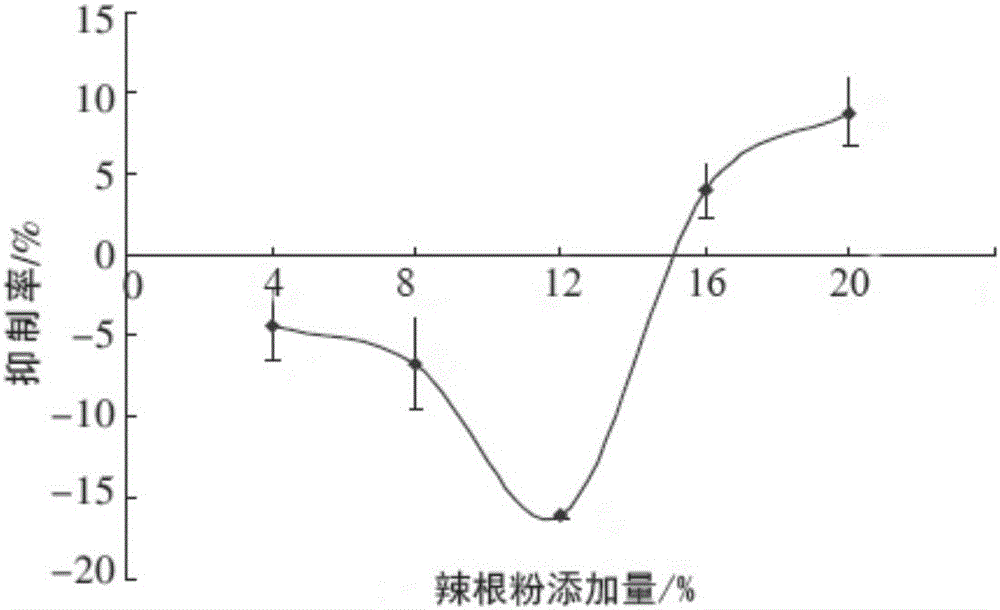

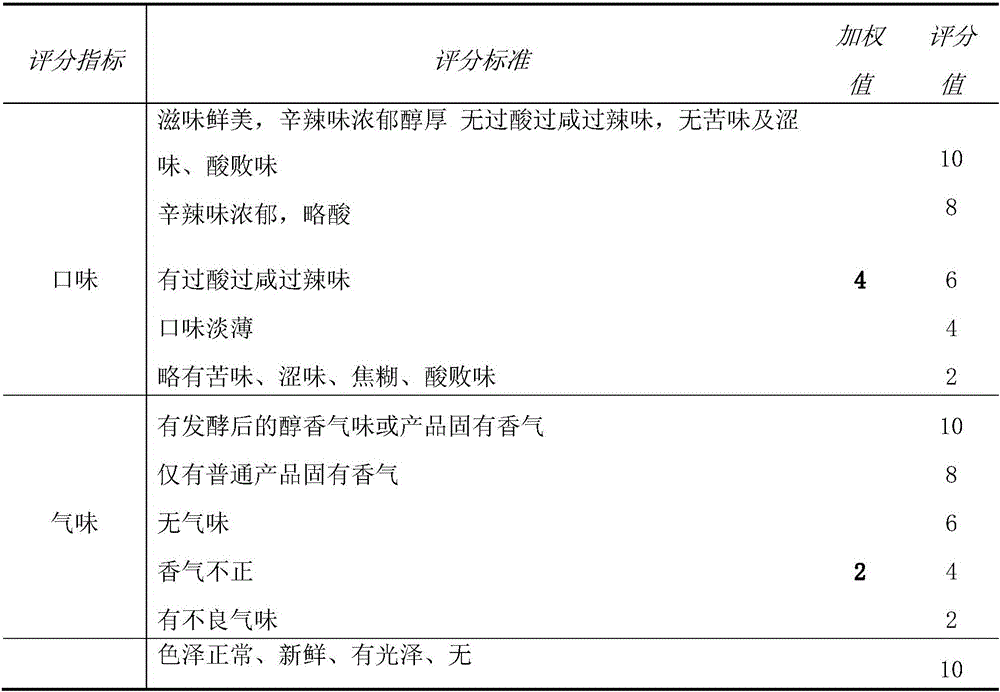

ActiveCN105995924AIncrease Flavor IntensityMeet needsFood preservationFood ingredient as flavour affecting agentOil phaseMyrosinase

The invention discloses a method for regulating and controlling the quality of horseradish sauce by fermentation. The method comprises the following steps: dissolving 20-22 percent of horseradish powder, 0.3-0.5 percent of xanthan gum and 3-5 percent of cane sugar, in mass percentage, in water to form an aqueous phase; and uniformly mixing ingredients of an oil phase including 5-6 percent of edible oil and 0.2-0.3 percent of stearin; uniformly mixing the aqueous phase and the oil phase, inoculating lactobacillus, and fermenting for 20-24 hours in a closed environment at a constant temperature; sterilizing the product and stopping fermentation treatment after the fermentation reaches the terminal; and cooling and filling to obtain a product. According to the method, reproduction of lactobacillus and activity of myrosinase of the lactobacillus are influenced by inoculating lactobacillus and regulating fermenting temperature, time and other conditions, so that the flavor, taste and nutritional quality of horseradish sauce can be regulated and controlled.

Owner:无锡食赫兹未来食品科技有限公司

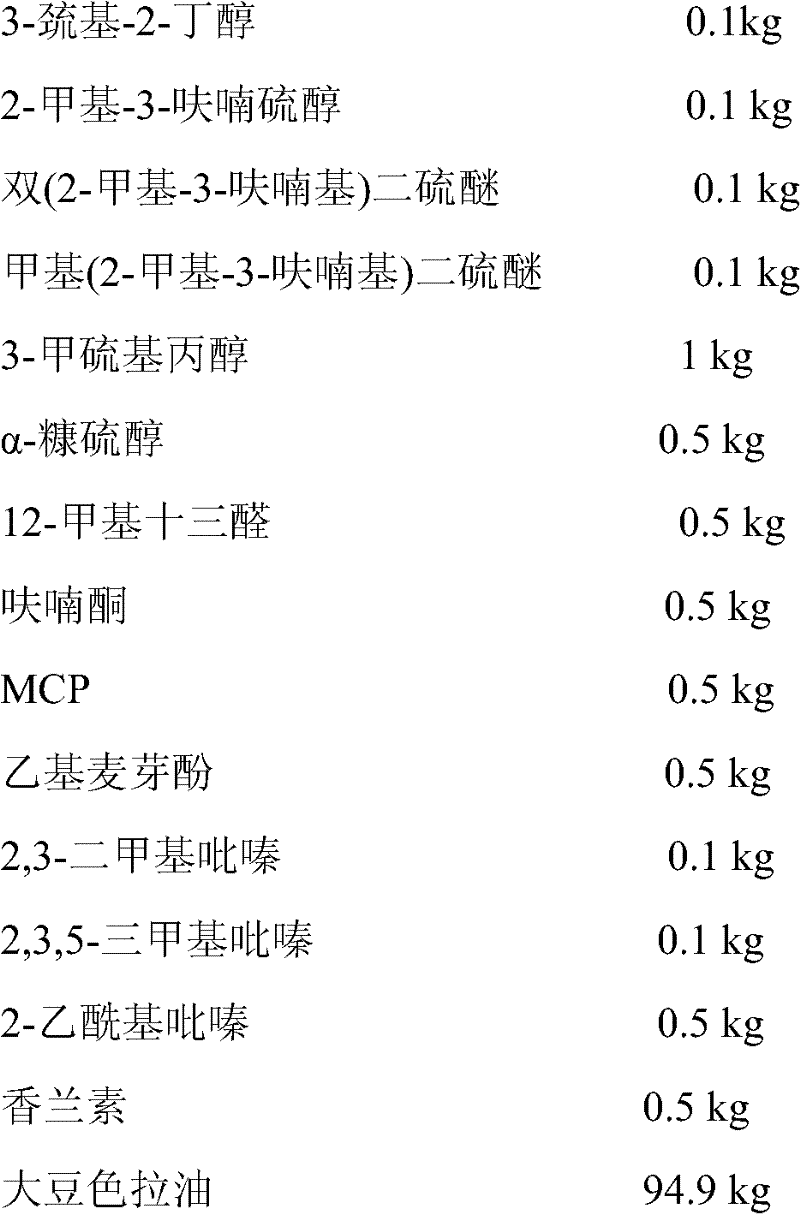

Preparation method of beef oily essence

The invention relates to a preparation method of a beef oily essence. The method comprises the following steps of: heating soybean salad oil to 80 DEG C; adding furanone, MCP (Monocalcium Phosphate), ethyl maltol, 2-acetylpyrazine and vanilline; stirring till the added materials are fully dissolved; adding 3-mercapto-2-butanol, 2-methy-3-furanthiol, bi(2-methy-3-furyl)disulfide, methyl(2-methyl-3-furyl)disulfide, 3-methylthio-propanol, alpha-furfurylmercaptan, 12-methyl tridecyl aldehyde, 2,3-dimethyl pyrazine and 2,3,5-trimethylpyrazine; and stirring uniformly and filling. In the essence product prepared with the method, flavor volatile substances contained in roast beef are adopted, and a formula is designed according to a reasonable proportion. The essence has the advantages of flavor of natural roast beef, vivid smell, natural fragrance, long lasting time and high thermal stability. The product is applied to seasonings, and has an irreplaceable function in the field of instant noodles.

Owner:TIANJIN CHUNFA BIO TECH GRP

Method for making cheese

InactiveUS20140348978A1Boost level of glutamateIncrease sensory qualityMilk preparationBacteriaPeptideChemistry

The present invention relates to a method for producing cheese with good flavour, especially low-salt cheese by using a lactic acid bacteria (LAB) starter culture which is glutamate decarboxylation (GAD) negative. The method may additionally involve inoculating the milk substrate with a GAD-negative Lb. helveticus strain having a high lytic and peptidolytic activity, which further releases glutamate into the milk Additional application of camel chymosin reduces bitterness.

Owner:CHR HANSEN HLDG AS +1

Potato derived flavour enhancing composition and method for the manufacture thereof

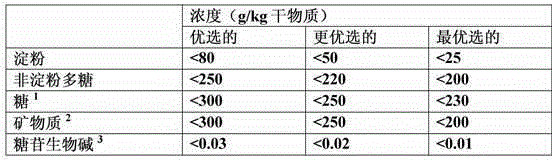

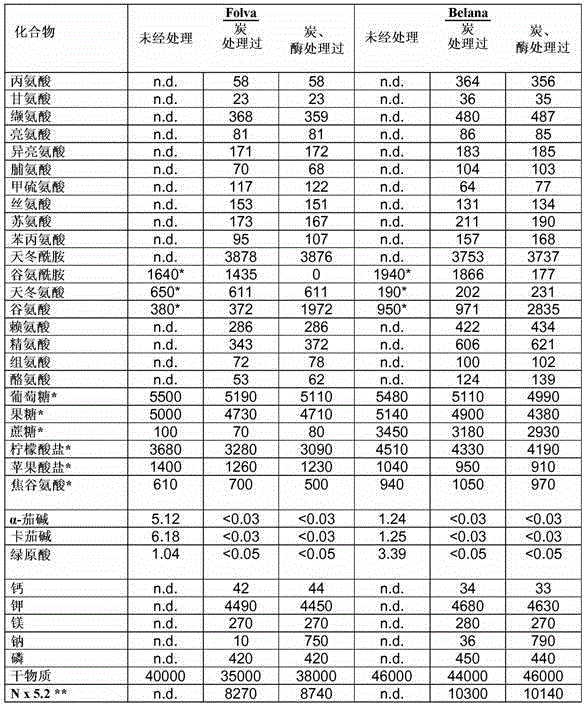

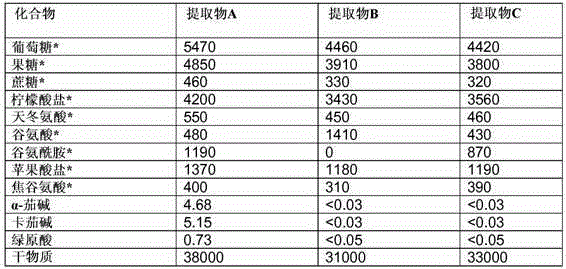

The present invention relates to a potato derived flavour enhancing composition having a dry matter content of at least 3 wt.% and containing per kg of dry matter: 150-900g of proteinaceous matter; 0-100g of starch; 0-5mg of chlorogenic acid; 0-30mg of glycoalkaloid selected from alpha-solanine, alpha-chaconine and combinations thereof; wherein free amino acids represent at least 80 wt.% of the proteinaceous matter, said free amino acids comprising: a first group of free amino acids selected from asparagine (Asn), aspartate (Asp), glutamate (Glu), glutamine (Gln), pyroglutamate (pGlu) and combinations thereof, said first group of free amino acids representing 45-95 wt.% of the free amino acids; a second group of free amino acids selected from glycine (Gly), leucine (Leu), lysine (Lys), serine (Ser), isoleucine (Ile) and combinations thereof, said second group of free amino acids representing 1 -20 wt.% of the free amino acids; at least 3.5 wt.% Glu; wherein the first group of free amino acids and the second group of free amino acids are present in a weight ratio of at least 4:1. The flavour enhancing composition according to the present invention is obtained by removing most of the starch and protein naturally present in potato, by additionally removing the bulk of glycoalkaloids (alpha-solanine, alpha-chaconine) that are endogenous to potato, and by retaining flavour enhancing components, including glutamate.

Owner:UNILEVER IP HLDG BV

Fish scale protein enzymolysis liquid and preparation method thereof

ActiveCN102613383BStrong aromaMellow tasteAnimal proteins working-upFood preparationHydrolysisOligopeptide

Owner:TIANJIN CHUNYU FOOD INGREDIENTS

Preparation method and application of strong-flavor peptide in soy sauce

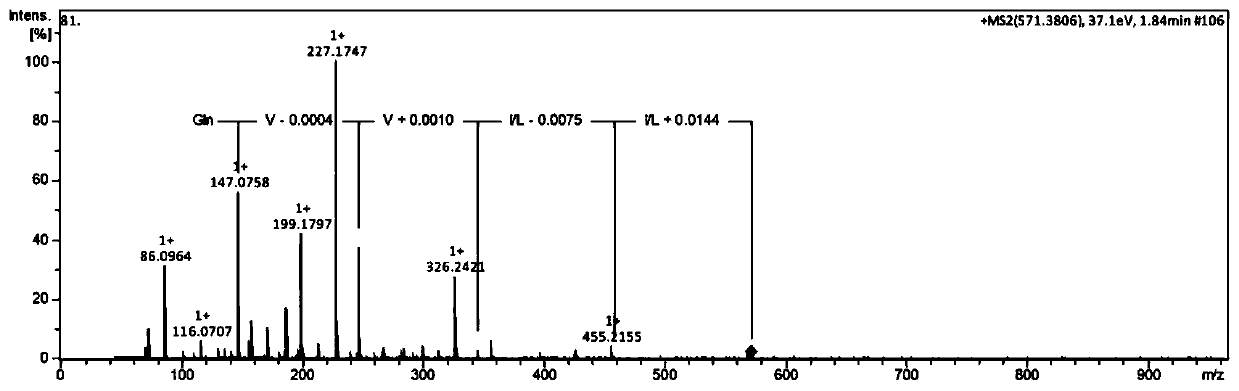

InactiveCN110477354AIncrease Flavor IntensityImprove savoryPeptide preparation methodsFermentationUltrafiltrationSolid phase extraction

The invention relates to a preparation method and application of a strong-flavor peptide in soy sauce. Soybean meal and wheat flour are used as raw materials, and original soy sauce is obtained through koji making and fermentation; the original soy sauce passes through an ultrafiltration membrane with the molecular weight of 5000 Da, and a permeate is taken. The strong-flavor peptide in a soy sauce sample is enriched from permeate by an Oasis MAX mixed anion solid phase extraction column. The amino acid sequence is identified to be Leu-Leu-Val-Val-Gln by UPLC-MS / MS. The strong-flavor peptide has good flavoring intensity, and can significantly improve the thick flavor of food at the concentration of 500 ppm, so the strong-flavor peptide can be widely applied in the fields of food and condiments.

Owner:珠海佳霖食品有限公司

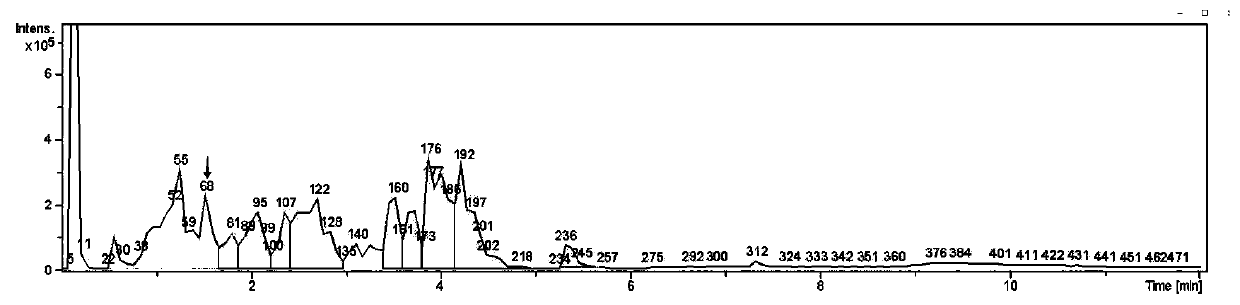

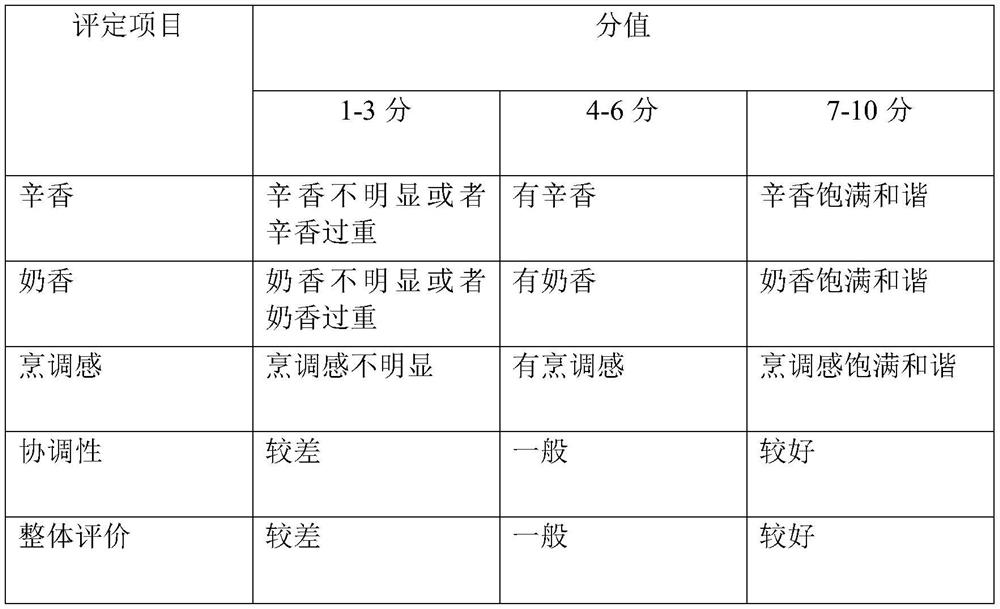

Tom-yum-kung essence and preparation method thereof

ActiveCN113647598AMake up for lost flavorIncrease Flavor IntensityClimate change adaptationFood ingredient as flavour affecting agentBiotechnologyAroma aroma

The preparation method of the Tom-yum-kung essence comprises the following steps: weighing the following substances in percentage by mass: 60.87% of citionella oil, 2.08% of sage oil, 4.48% of basil oil, 6.04% of citral, 13.3% of coconut aldehyde, 11.04% of geranium oil, 0.31% of garlic oil and 1.88% of celery seed oil, and uniformly mixing to obtain a spicy base; weighing the following substances in percentage by mass: 7.5% of spicy base, 0.6% of capsanthin E-150 and 91.9% of soybean oil, and uniformly mixing to obtain the Tom-yum-kung essence. The Tom-yum-kung essence has perineum-function characteristic flavor, is moderate in spicy flavor and milk flavor, relatively strong in cooking feeling, good in aroma coordination and more vivid.

Owner:TIANJIN CHUNFA BIO TECH GRP

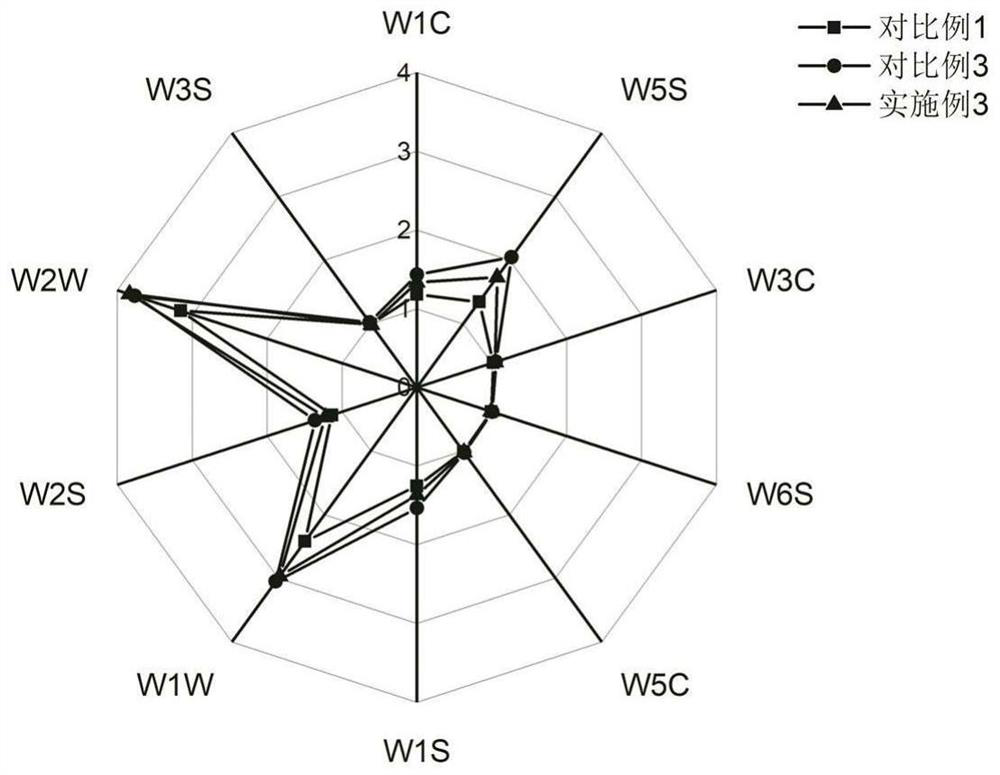

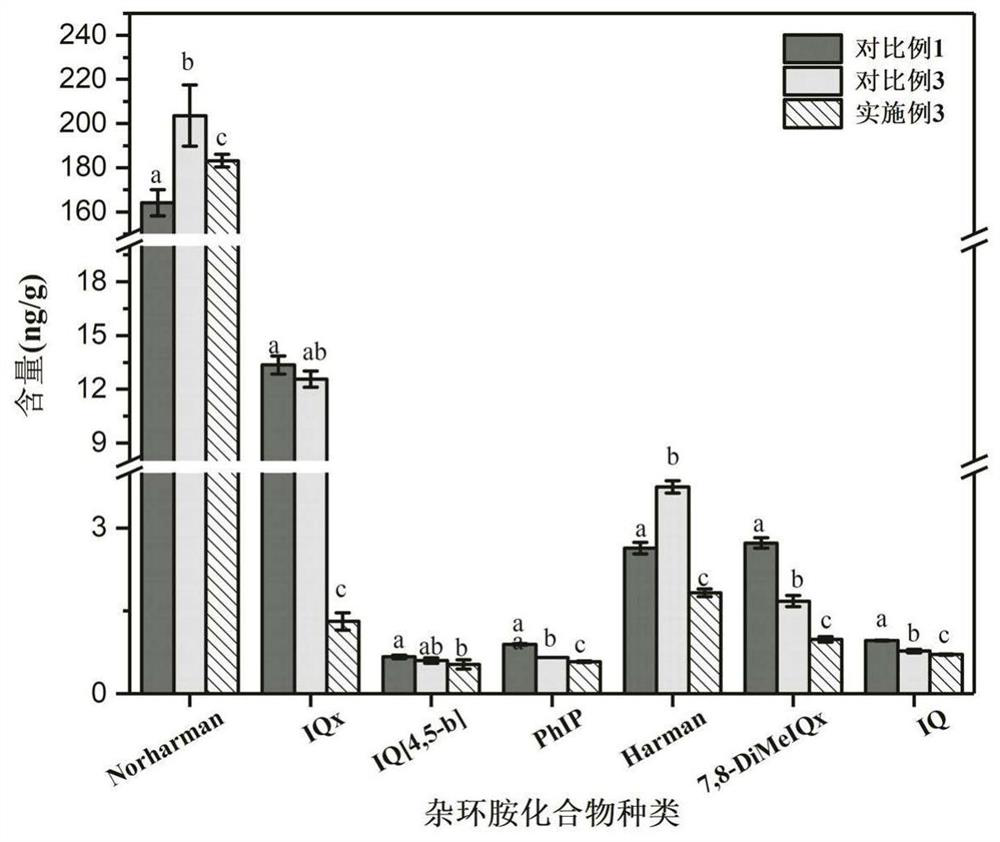

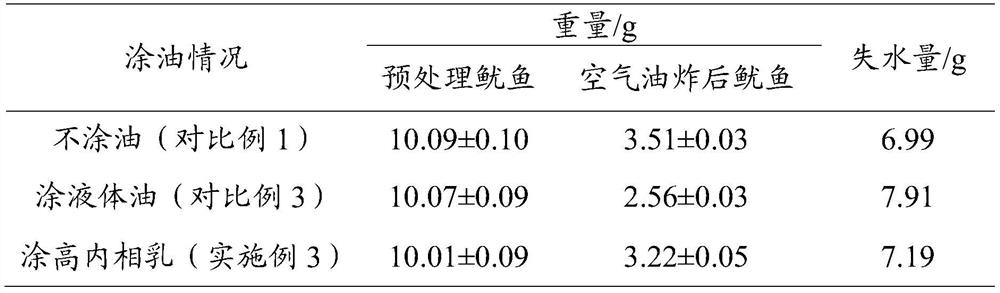

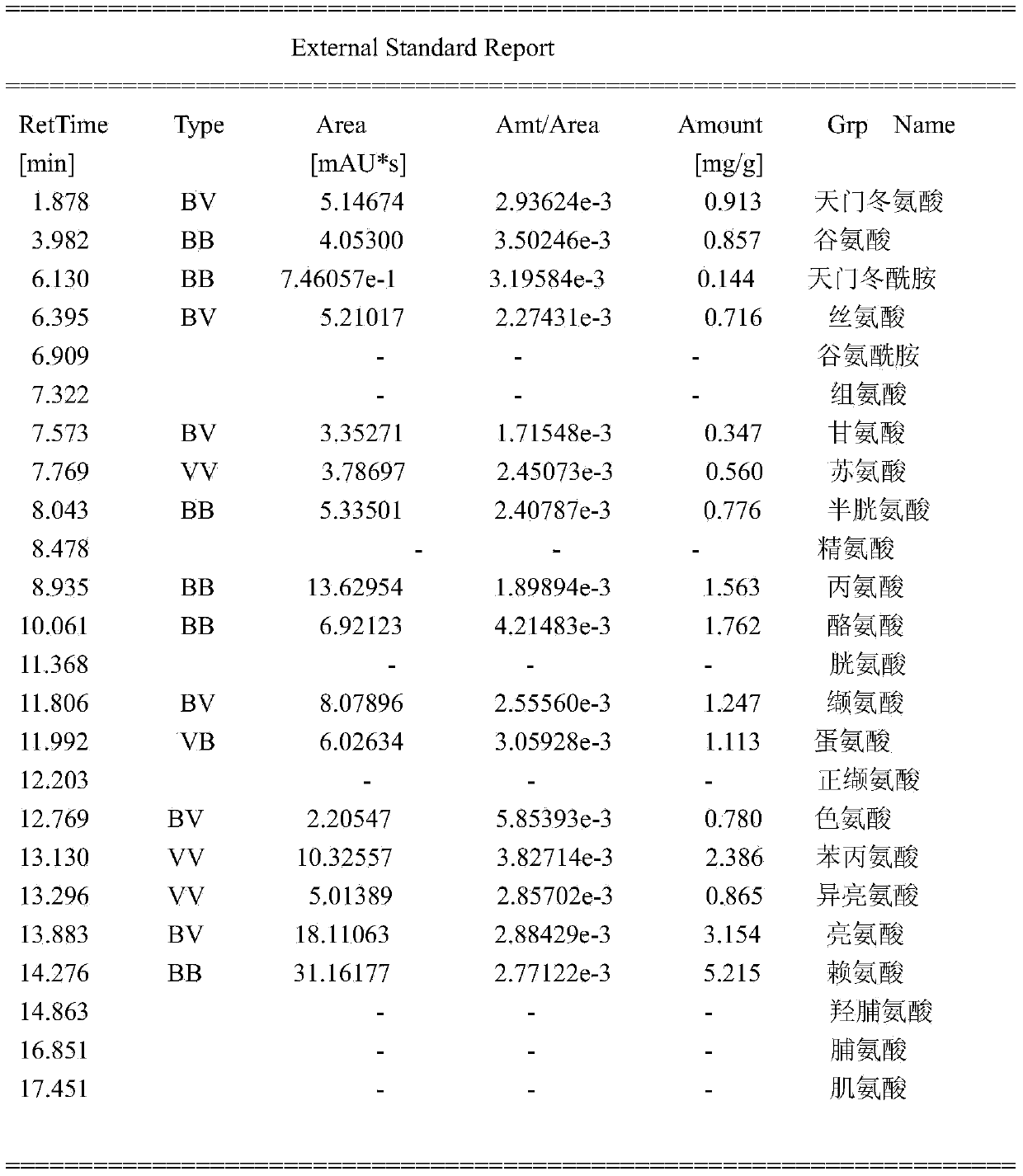

Method for air-frying seafood based on immobilized grease

The invention discloses a method for air-frying seafood based on immobilized grease. The method comprises the following steps: smearing casein-stabilized high internal phase emulsion on the surface ofthe seafood for air-frying to obtain the air-fried seafood. By utilizing the immobilization effect of the high internal phase emulsion on the grease, the flowability of the grease is changed, and thegrease coating uniformity is ensured; and the appearance and the texture of the air-fried low-fat-content seafood are improved. The obtained product is uniform in surface color, crispy in surface andrich in elasticity inside. Meanwhile, the production of heterocyclic amine can be effectively reduced; the high-internal-phase emulsion shows physical properties such as spreadability and plasticityin application, and can be widely applied to food baking and deep-frying to replace hydrogenated oil and ester exchange grease.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Preparation method of little yellow croaker enzymatic hydrolysis liquid

InactiveCN104041785AStrong meat textureIncrease Flavor IntensityFood preparationFlavorEnzymatic hydrolysis

The invention relates to a preparation method of little yellow croaker enzymatic hydrolysis liquid. The preparation method comprises the following steps: stirring frozen little yellow croakers, trypsin and compound protease in a reactor for 3-5 minutes, heating, enzymatically hydrolyzing at reaction temperature of 55-70 DEG C for 0.5-2 hours, after the enzymatic hydrolysis is finished, heating to 80-100 DEG C, performing enzyme deactivation for 10-20 minutes, after the enzyme deactivation is finished, cooling to 30-40 DEG C, standing at room temperature for 15-30 minutes, filtering by a 40-mesh sieve to remove residues, and collecting filter liquor, namely the little yellow croaker enzymatic hydrolysis liquid, wherein the additive amounts of the trypsin and the compound protease are respectively 0.05%-0.2% of the weight of the frozen little yellow croakers. The little yellow croaker enzymatic hydrolysis liquid is prepared by different enzymatic hydrolysis proteases; compared with enzymatic hydrolysis liquid prepared from single enzymatic hydrolysis protease, the obtained little yellow croaker enzymatic hydrolysis liquid has the advantages that meat is good in texture, high in flavor intensity and mellow in mouth feel, and the shortcoming of relatively poor overall flavor after enzymatic hydrolysis is carried out by the single protease is overcome.

Owner:TIANJIN CHUNFA BIO TECH GRP

Flavored oil and preparation method thereof

PendingCN114075476AIncrease Flavor IntensityPure flavorFatty-oils/fats refiningEssential-oils/perfumesReducing sugarFlavor

The invention provides flavor oil and a preparation method thereof. Specifically, the invention provides a method for preparing flavor oil or a method for reducing the irritant flavor of enzymatic flavor oil and / or improving the stir-frying flavor, burnt flavor and / or salty flavor of the enzymatic flavor oil. The method comprises the following steps: (1) performing enzymolysis on oil in an oil phase environment to obtain zymolyte; and (2) carrying out heat treatment on the zymolyte obtained in the step (1), and then separating to obtain the flavor oil. The method disclosed by the invention does not need to add amino acid and reducing sugar, is simple in process, free of a drying step, low in water content and easy in material separation. Compared with a water phase enzymolysis-Maillard system, the method has the advantages that an oil phase system is adopted for reaction, and the obtained enzymolysis flavor oil is higher in flavor strength and pure in flavor.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

A method for regulating the quality of horseradish sauce by fermentation

ActiveCN105995924BIncrease Flavor IntensityMeet needsFood preservationFood ingredient as flavour affecting agentBiotechnologySucrose

Owner:无锡食赫兹未来食品科技有限公司

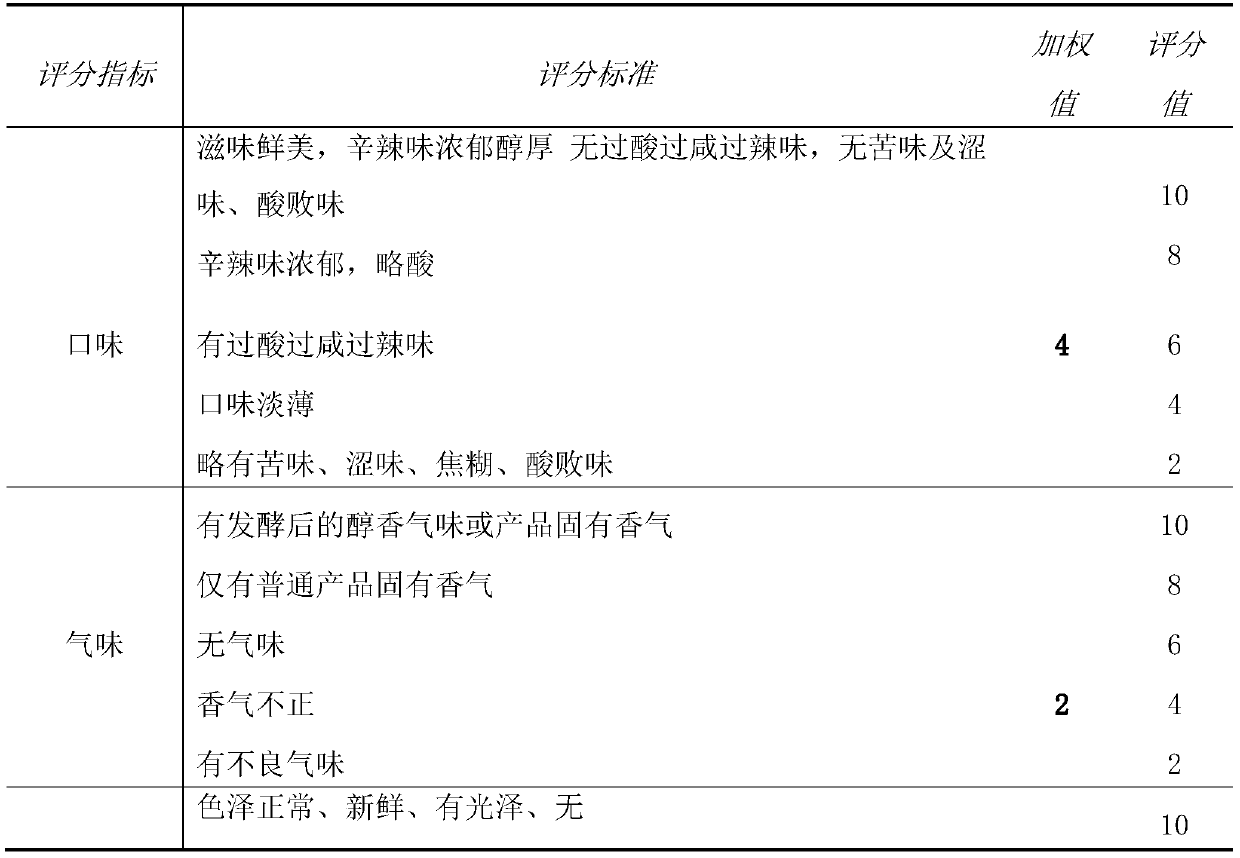

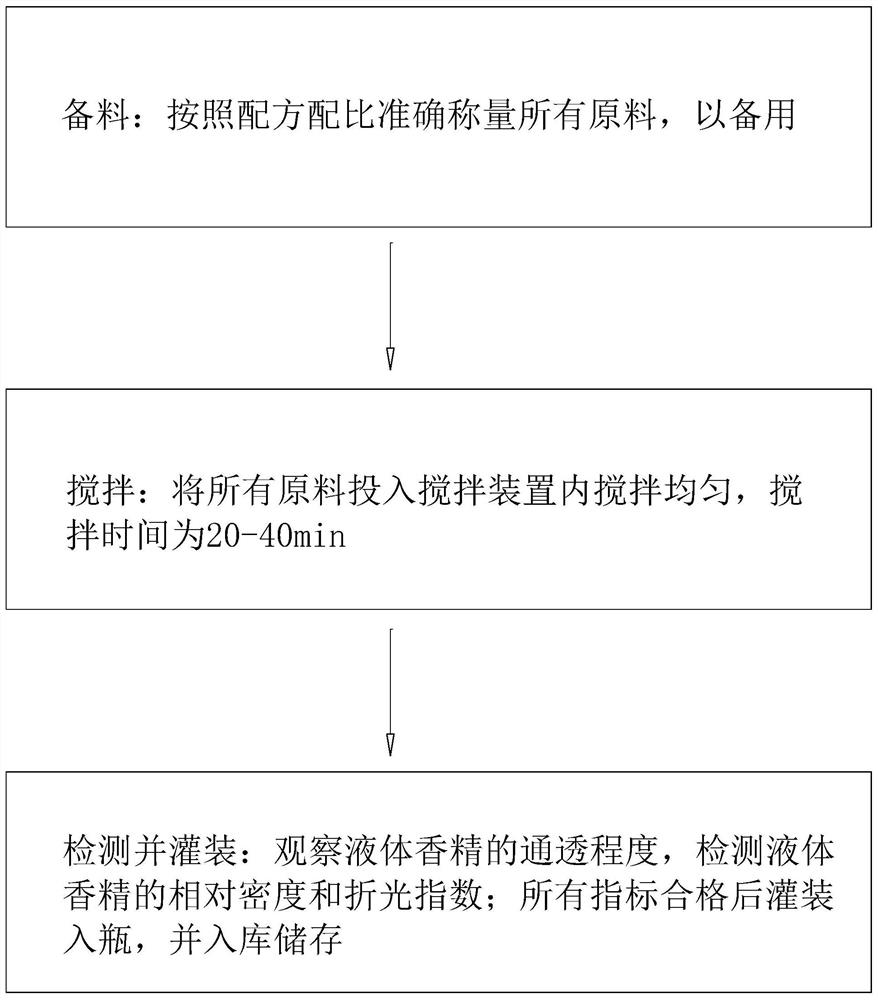

Plum liquid essence for cigarettes and production process thereof

PendingCN111944611AIncrease flavor intensityImprove fragranceTobacco preparationEssential-oils/perfumesCocoa PowdersSmoked Plum

The invention relates to plum liquid essence for cigarettes and a production process thereof. The liquid essence is prepared from the following raw materials in parts by weight: 50-70 parts of ethanol, 5-12 parts of smoked plum extract, 1-5 parts of wild jujube powder, 2-6 parts of plum juice, 1-3 parts of cocoa powder, 1-5 parts of red date powder, 2-8 parts of propylene glycol, 3-9 parts of deionized water, 2-8 parts of 2-methylvaleric acid and 2-6 parts of butylated hydroxyanisole. The preparation method of the liquid essence comprises the following steps: preparing materials, stirring, detecting and filling. The liquid essence has the effect of improved flavor richness.

Owner:NANTONG YUANYA PRECISION MACHINERY

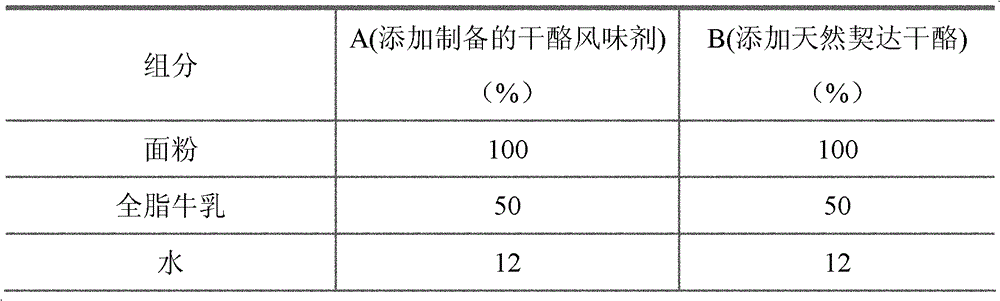

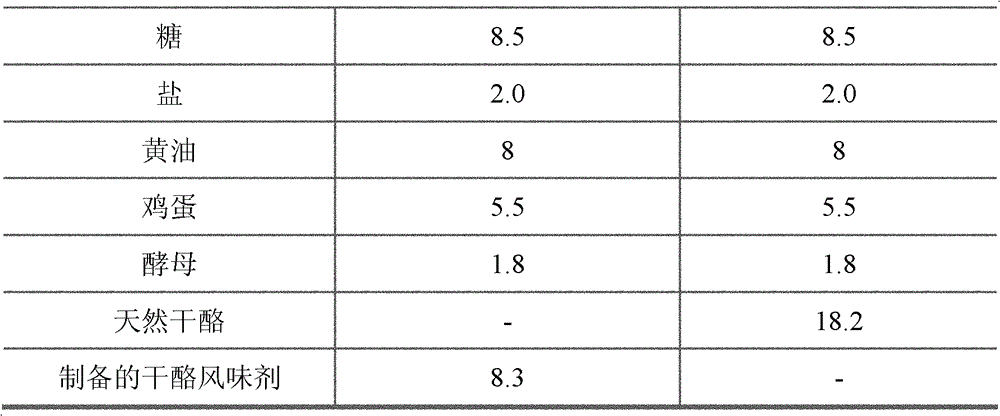

Method for preparing salmon pink cheese flavoring agent

The invention relates to a method for preparing a salmon pink cheese flavoring agent. The method comprises the following steps of: performing processes such as crushing, enzymolysis, surface bacteria spraying, spray drying and the like on fresh cheese curds to prepare a salmon pink food flavor substance, namely the cheese flavoring agent. Surface curing bacteria related in the method can decompose cysteine and methionine in the cheese to form a key flavor component of the cheese, namely a volatile aromatic sulfur compound with the flavor intensity 5 to 30 times that of natural cheese; only a small amount of the volatile aromatic sulfur compound can provide intense cheese flavor, and the cost is greatly reduced than that of the natural cheese. Besides, the flavor intensity of a finished product is high, so the required cheese flavor intensity can be achieved by using only a small amount of the finished product; therefore, the processed food has less fat and lactose, and low-fat cheese flavor food can be produced.

Owner:山东百慧乳业股份有限公司

Production method for step-by-step fermentation of peanut meal by bacillus velezensis and pediococcus acidilactici and application thereof

ActiveCN114631601AImprove functional propertiesImprove featuresBacteriaFood processingBiotechnologyArginine

The invention relates to a production method for step-by-step fermentation of peanut meal by bacillus velezensis and pediococcus acidilactici, belongs to the technical field of biology, and mainly aims to provide a fermentation process for improving functional characteristics and nutritional level of peanut meal. The invention also discloses the fermented peanut meal prepared by the process and application of the fermented peanut meal in reducing the abdominal fat percentage of broilers and improving the meat quality. The fermentation method of the peanut meal comprises the steps of raw material pretreatment, first-stage fermentation, adjusting and discharging, second-stage fermentation, adjusting and discharging and the like. According to the fermented peanut meal prepared through the fermentation technology, the total flavone content, the oxidation resistance, the crude protein content, the acid-soluble protein content, the total acid content, the total unsaturated fatty acid content and the partial essential amino acid content are remarkably increased, the arginine / lysine proportion is closer to the ideal amino acid proportion, and AFB1 and phytic acid are remarkably degraded. By adding the fermented peanut meal into the broiler feed, the abdominal fat percentage of the broiler at the age of 42 days can be remarkably reduced, the flavor characteristic of chest muscles is improved, the contents of intramuscular proteins, total amino acids, flavor amino acids and monounsaturated fatty acids are remarkably increased, the pH reduction is slowed down, and the shelf life is prolonged.

Owner:TIANJIN BIOFEED TECH CO LTD +1

Beef oily essence and preparation method thereof

The invention relates to beef oily essence and a preparation method thereof. The essence is prepared from the following raw materials: 3-sulfydryl-2-butanol, 2-methyl-3-furanthiol, bis(2-methyl-3-furyl) disulfide, methyl(2-methyl-3-furyl) disulfide, 3-methylmercapto-propyl alcohol, alpha-furfurylmercaptan, 12-methyl tridecylic aldehyde, furanone, methylcyclopentadienyl pregnenolone (MCP), ethyl maltol, 2,3-dimethylpyrazine, 2,3,5-trimethylpyrazine, 2-acetyl pyrazine, vanillin and soybean salad oil. The invention also provides a preparation method for the essence. In an essence product prepared by the method, flavor volatile substances contained in roast beef are adopted, and a formula is formulated in a reasonable ratio, so the beef oil essence has the flavor of natural roast beef, vivid and natural fragrance, long fragrance retention and high heat stability. The beef oily essence has an irreplaceable effect in fields of seasonings and instant noodles.

Owner:TIANJIN CHUNFA BIO TECH GRP

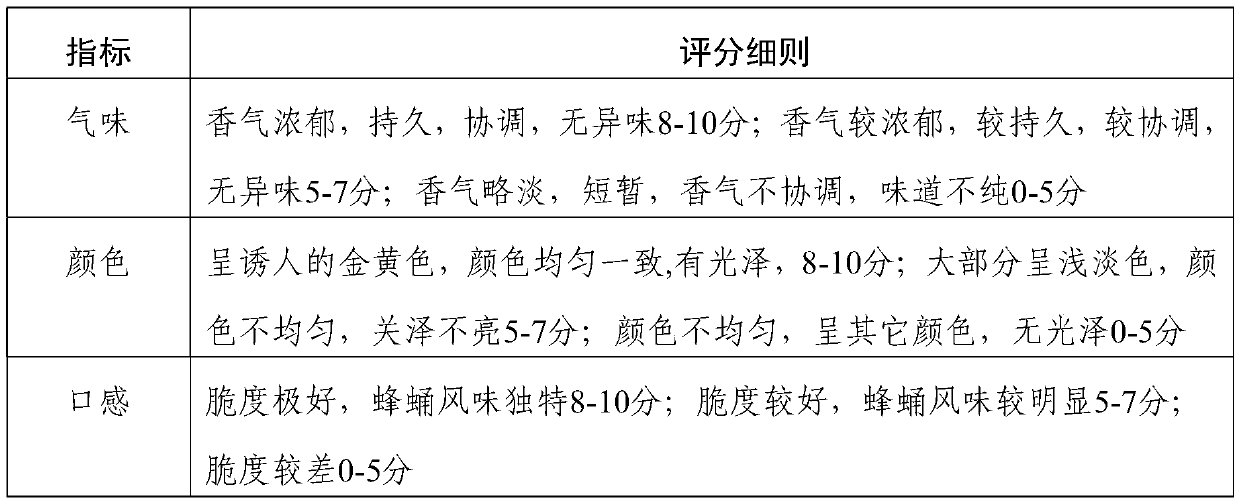

Honeybee pupae puffing food and preparation method thereof

The invention relates to honeybee pupae puffing food and a preparation method thereof. The preparation method comprises the following steps of (1) preparing honeybee pupae oil; (2) carrying out enzymolysis on honeybee pupae; (3) preparing a honeybee pupae composite agent; (4) preparing honeybee pupae particles; and (5) puffing. According to the honeybee pupae puffing food and the preparation method thereof provided by the invention, components such as unsaturated acid in the honeybee pupae oil are reserved, the loss of nutrition in the preparation process is avoided, the honeybee pupae use ratio is improved, and amino acid and polypeptide are produced through the enzymolysis of the honeybee pupae and carry out Maillard reaction with honey, so that the flavor intensity of a honeybee pupae product is improved, the safe and healthy leisure honeybee pupae food with delicious and pure flavor and crisp taste is obtained, the honeybee pupae product type is further enriched, and a honeybee pupae food development range is widened.

Owner:伊犁哈萨克自治州农业农村局

Meaty reaction essence prepared by using enzymatic hydrolysate for larvae of barley pests

Owner:TIANJIN CHUNFA BIO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com