Flavored oil and preparation method thereof

A flavored oil and flavor technology, applied in the direction of oil/fat refining, oil/fat production, fat production, etc., can solve the problems of long steaming and frying time, difficult to achieve stable realization, and difficult to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

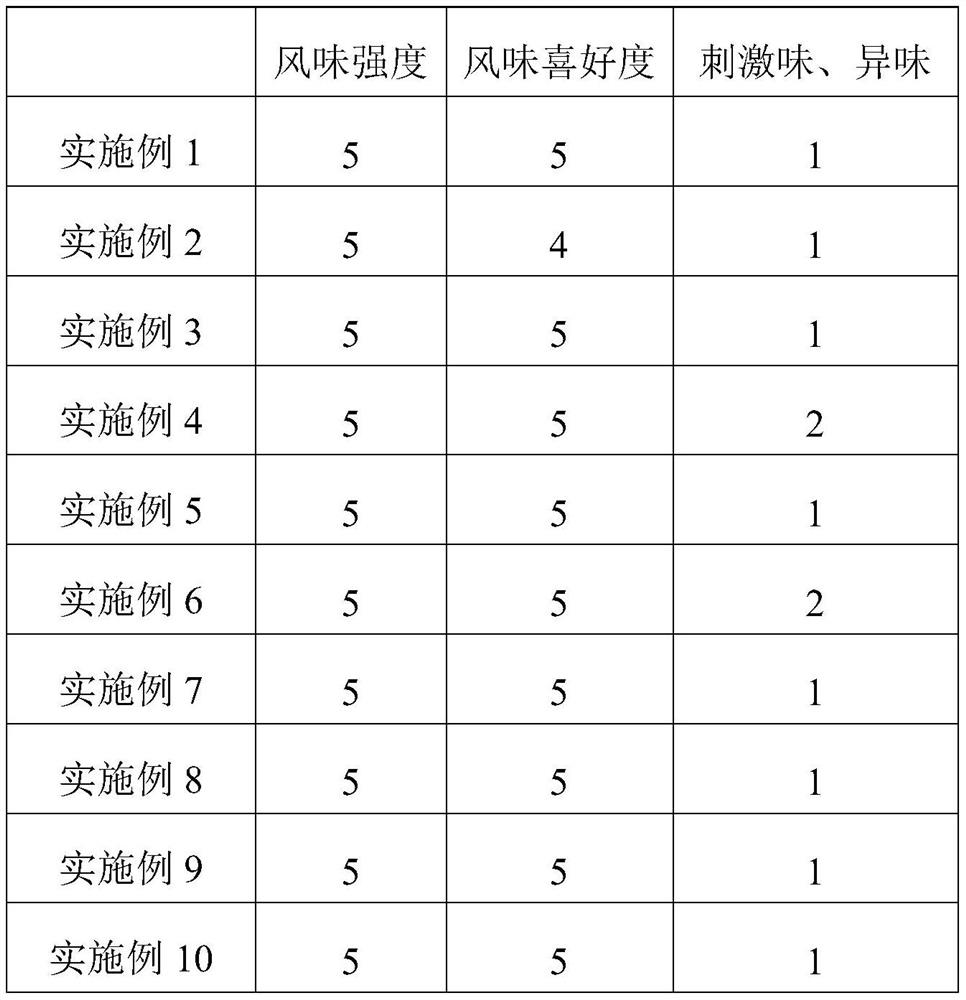

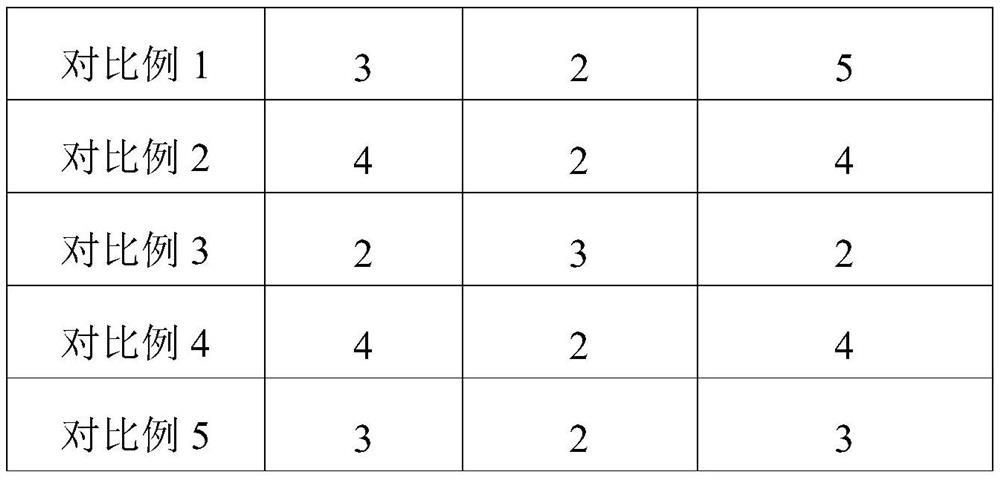

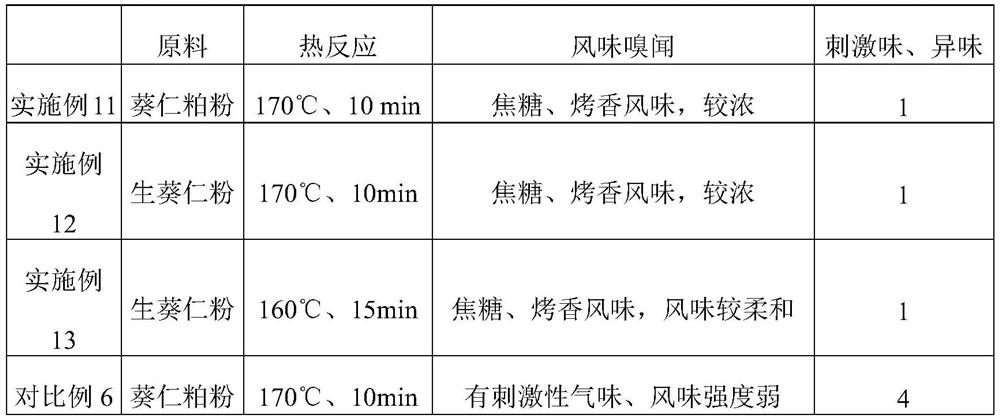

[0067] Compared with the prior art, the method for preparing flavor oil of the present invention has the following advantages:

[0068] (1) Compared with the water-phase enzymolysis-Maillard system, the present invention adopts the oil phase system to carry out the enzymolysis reaction, and the flavor oil obtained has higher flavor intensity, weaker pungent smell and pure flavor;

[0069] (2) The invention has simple process, no drying step, low water content and easy separation of materials.

[0070] The present invention finds that adding the enzymatic flavored oil of the present invention to the oil can improve the flavor intensity and flavor preference of the oil without bringing obvious irritating and peculiar smell, that is, the enzymatic flavored oil of the present invention can be used as A fragrant oil (also known as aroma oil) to improve the flavor of oils and fats.

[0071] Therefore, the present invention also includes an oil composition containing the enzymatic f...

Embodiment 1

[0080] Take 100g of rapeseed, crush it, add 300g of primary refined rapeseed oil, heat to 50°C with stirring, add 30mL of sodium dihydrogen phosphate-disodium hydrogen phosphate buffer solution with pH=8, and then add 1wt% by weight of rapeseed Alkaline protease, 3wt% flavor protease, 0.5wt% mid-temperature amylase, 1wt% complex glucoamylase and 1wt% pectinase were reacted at 50°C, and the mother liquor was obtained after 4 hours of reaction. The mother liquor is put into a high-temperature and high-pressure reactor, reacted at 170°C for 10 minutes, and the oil phase is separated to obtain the fragrant rapeseed oil.

Embodiment 2

[0082] Take 100g of rapeseed, crush it, add 300g of primary refined rapeseed oil, heat to 50°C under stirring, add 30mL of sodium dihydrogen phosphate-disodium hydrogen phosphate buffer solution with pH=7, and then add 0.5wt % alkaline protease, 1.5wt% flavor protease, 3wt% mesophilic amylase, 0.6wt% compound glucoamylase and 2wt% pectinase were reacted at 50°C for 4 hours to obtain mother liquor. The mother liquor is put into a high-temperature and high-pressure reactor, reacted at 170°C for 10 minutes, and the oil phase is separated to obtain the fragrant rapeseed oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com