Potato derived flavour enhancing composition and method for the manufacture thereof

A flavor enhancement and composition technology, which is applied in the field of edible products and potato-derived flavor enhancement compositions, can solve problems such as increased bitterness and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

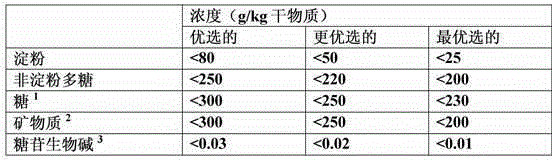

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

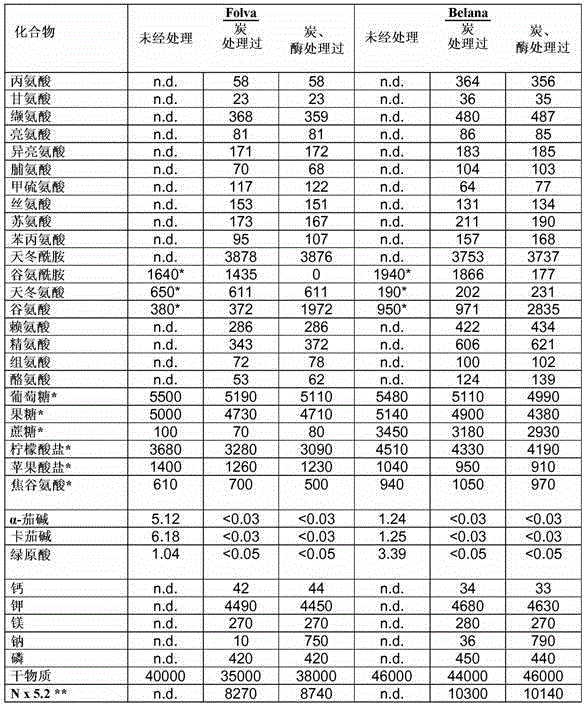

[0129] Two potato varieties (Folva, untreated potatoes, and Belana, peeled potatoes packed in a protective atmosphere) obtained from a local Dutch supermarket were used as raw materials.

[0130] 10 kg of potatoes were peeled (if necessary), grated with a kitchen food processor fitted with a grater disk, and then minced with a double-edged knife at high speed for at least one minute. The potato slurry was filtered under vacuum through a No. 2 sintered glass funnel, and the filtrate was boiled in a pot for at least 7 minutes. The precipitate formed during the heating was now removed by a second filtration under vacuum using a Büchner funnel fitted with Whatman No. 595 filter paper. The filter cake was discarded and the filtrate was cooled with ice water.

[0131] To 1.8 kg of the second filtrate was added 0.2% glutaminase (SD-C100S from Amano) and the mixture was incubated in a thermostatic double-walled glass vessel at 55°C for 30 minutes. Subsequently, the temperature of this...

Embodiment 2

[0142] The Folva potatoes were peeled, grated with a kitchen food processor fitted with a grater disc, and then minced with a double edged knife at high speed for at least one minute. The potato slurry was filtered under vacuum through a No. 2 sintered glass funnel, and the filtrate was boiled in a pot for at least 7 minutes. The precipitate formed during the heating was now removed by a second filtration under vacuum using a Büchner funnel fitted with Whatman No. 595 filter paper. The filter cake was discarded and the filtrate was cooled with ice water.

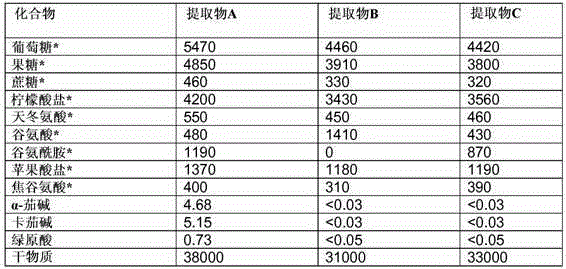

[0143] 200 mL of the second filtrate (Extract A) was concentrated four-fold by rotary evaporation at 40 °C. The resulting 50 mL concentrate was applied to a 32x2.6 cm column packed with Amberlite FPX66 (Dow Chemical) and eluted with water at 10 mL / min using a ?ktaExplorer FPLC (PharmaBiotech, GE Healthcare Life Sciences). 200 mL of eluate was collected and divided into two sub-fractions.

[0144] To one subfraction (extra...

Embodiment 3

[0152] In a further quantitative evaluation, a trained panel of ten subjects was employed, who ranked the five samples in order of increasing umami intensity in the first step, and ranked them on a 15-point scale in the second step Score the samples above. The panel has been trained to rank and score using different concentrations of monosodium glutamate in water.

[0153] Fractions derived from Folva potatoes and described and characterized in Example 1 (Table 1) were diluted to the required glutamic acid levels. Potassium citrate was added to samples (including MSG reference) to bring it up to 0.19%, as needed. When needed, fructose and glucose were added to standard levels of 0.18% and 0.28%, respectively, and the pH was corrected to 6.2 with 1M KOH.

[0154] The samples tested by the panel and the results obtained therefrom are shown in Table 3. These results show that fractions scored higher on "umami" than expected based on their glutamic acid concentrations.

[0155...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com