Chicken umami peptide and preparation method and application thereof

A technology of umami peptide and chicken, which is applied in the direction of application, protein components of meat, and food ingredients as taste improvers, etc., can solve the problems of weak taste intensity and poor solubility of chicken powder, etc. The effect of high flavor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Use chicken breast meat as raw material, pass it through a meat grinder, add 0.05% papain and 0.05% flavor protease (produced by fermentation of Aspergillus oryzae) to 1kg of chicken breast weight, and enzymolyze it at 50°C and pH 6.0 For 24 hours, the degree of hydrolysis of chicken protein reached 46.7%, and the enzyme was kept at 95°C for 10 minutes to obtain chicken enzymatic solution;

[0031] (2) passing the chicken enzymatic hydrolyzate through an ultrafiltration membrane with a molecular weight cut-off of 10kDa, and getting the permeate;

[0032] (3) Add ethanol to the permeate until the ethanol concentration is 90% (v / v) to precipitate macromolecular proteins and polypeptides, and take the supernatant;

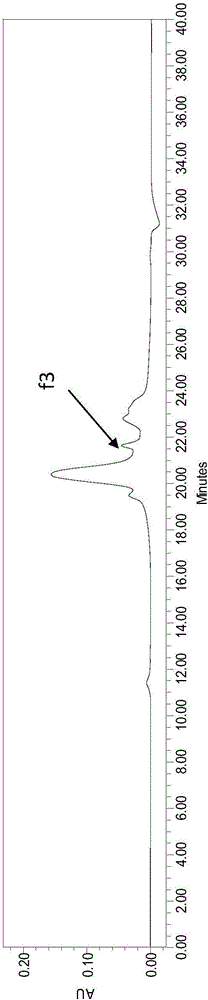

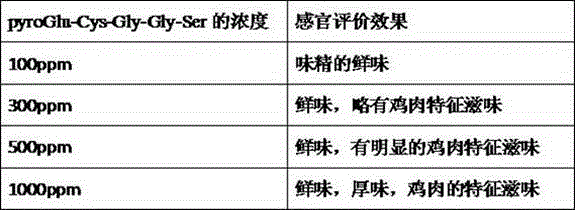

[0033] (4) The supernatant is passed through the gel chromatographic column SuperdexPeptide10 / 300GL, and the 3rd peak is collected (see figure 1 ), which is the umami peptide. The structural identification of the umami peptide was carried out by liquid-ma...

Embodiment 2

[0038] (1) Take 5kg chicken breast meat as raw material, pass it through a meat grinder, add 0.1% alkaline protease (from Bacillus subtilis) and 0.2% flavor protease (produced by fermentation of Aspergillus oryzae) of the weight of chicken breast meat at 60°C, pH value Under the condition of 8.0 for 18 hours, the degree of hydrolysis of chicken protein reached 41.9%, and kept at 90°C for 15 minutes to inactivate the enzyme, and the chicken enzymatic solution was obtained;

[0039] (2) passing the chicken enzymatic hydrolyzate through an ultrafiltration membrane with a molecular weight cut-off of 10kDa, and getting the permeate;

[0040] (3) Add ethanol to the permeate until the ethanol concentration is 80% (v / v) to precipitate macromolecular proteins and polypeptides, and take the supernatant;

[0041] (4) Pass the supernatant through the gel chromatography column SuperdexPeptide10 / 300GL, and collect the third peak, which is the umami peptide. The structural identification of...

Embodiment 3

[0043](1) Take 3kg chicken breast meat as raw material, pass it through a meat grinder, add 0.3% flavor protease and 0.2% bromelain by weight of chicken breast meat, and enzymolyze it for 12 hours at 55°C and a pH value of 7.0 to hydrolyze chicken protein When the temperature reaches 49.8%, keep at 92°C for 12 minutes to inactivate the enzyme, and obtain the chicken enzymatic hydrolyzate;

[0044] (2) passing the chicken enzymatic hydrolyzate through an ultrafiltration membrane with a molecular weight cut-off of 10kDa, and getting the permeate;

[0045] (3) Add ethanol to the permeate until the ethanol concentration is 85% (v / v) to precipitate macromolecular proteins and polypeptides, and take the supernatant;

[0046] (4) Pass the supernatant through the gel chromatography column SuperdexPeptide10 / 300GL, and collect the third peak, which is the umami peptide. The structural identification of the umami peptide by liquid-mass showed that its primary structure was pyroGlu-Cys-G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com