Preparation method of microcapsule type fermented cream flavored powder

A cream and microcapsule technology is applied in the field of preparation of microcapsule type fermented cream flavor powder, which can solve the problems of poor product dispersibility and stability, insufficient strength and fineness of taste, and single fragrance, and achieves high flavor strength, Good aroma retention and flavor stability, strong aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Fermentation: take by weighing 200g of sterilized cream (fat content 35%-40%, mass concentration).

[0023] 2. Add co-substrates: add desalted whey powder with a mass concentration of 15% cream and whole milk powder with a mass concentration of 15% cream as co-substrates, mix with cream evenly and sterilize at 85°C for 5 minutes Afterwards, cool down to inoculation temperature.

[0024] 3. Fermentation: Inoculate 0.2g of lactic acid bacteria starter powder under aseptic conditions (a mixed strain of Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremorfat, produced by Dutch DSM company), mix well and place in a constant temperature incubator Incubate at 25°C for 21h.

[0025] 4. Add wall material: Add 36g of β-cyclodextrin and 2.4g of sodium caseinate to the fermented cream that has reached the end of fermentation, then add 80mL of distilled water at 20°C to dissolve, and mix with a stirrer at 1000r / min for 2min.

[0026] 5. Spray drying: control th...

Embodiment 2

[0028] The formula of the preparation process of microencapsulated fermented cream flavor powder is: 100g of cream with 35%-40% fat content, 15g of desalted whey powder, 15g of whole milk powder, 0.1g of lactic acid bacteria starter bacteria powder (Lactococcus lactis Lactococcus lactis subsp. cremoris and the mixed strain of Lactococcus lactis subsp. cremoris, produced by Dutch DSM company), β-cyclodextrin 18g, sodium caseinate 1.2g, distilled water 40mL. The spray drying conditions are as follows: the inlet air temperature is 170°C, the outlet air temperature is 90°C, the feed rate is 55L / h for spray drying, and the tower bottom product is collected and sealed for storage.

[0029] The added 35%-40% cream can be prepared by separating antibiotic-free raw milk through a cream separator and sterilized for later use. Prepared by the method of the present invention, the mesophilic lactic acid bacteria starter acts on the cream, and after fermenting at a constant temperature of 3...

Embodiment 3

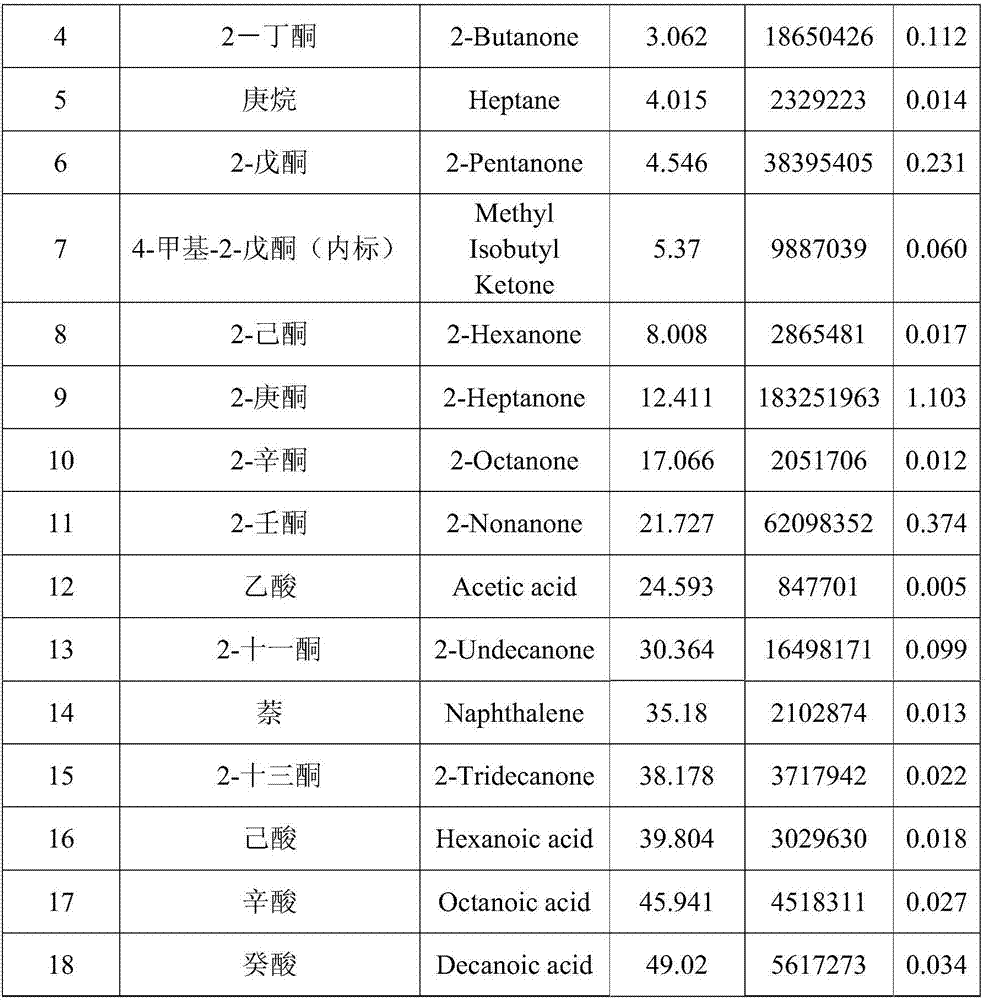

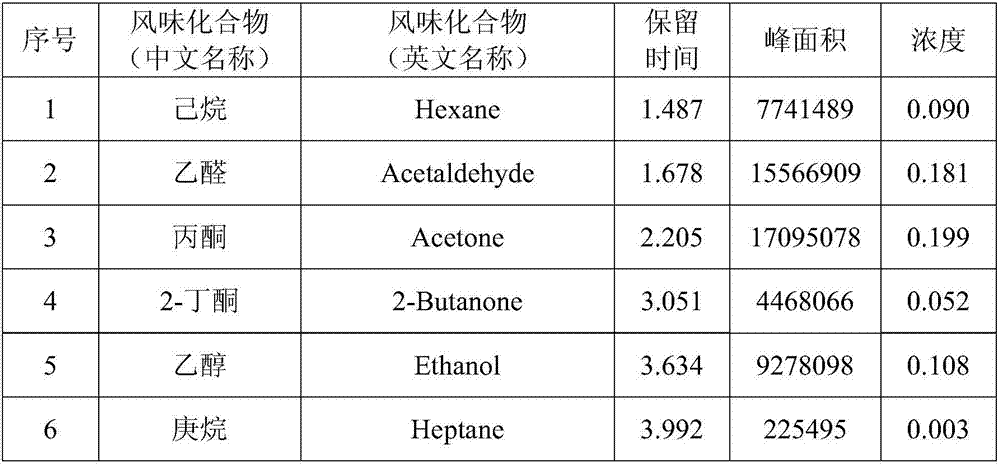

[0031] Using cream with a fat content of 35%-40% as raw material (100g), adopt mesophilic starter bacteria powder (a mixed strain of Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremorfat, produced by DSM in the Netherlands) For the fermentation experiment, the fermentation temperature was set at 30° C., and the fermentation time was set at 15 hours. Solid-phase microextraction-gas chromatography-mass spectrometry was used to determine the flavor components in unfermented cream and fermented cream, and the results found that hexane, dimethyl sulfide, acetone, 2-butanone, heptane, 2-pentanone, 2-hexanone, 2-heptanone, 2-octanone, 2-nonanone, acetic acid, 2-undecanone, naphthalene, 2-tridecanone, hexyl Acid, caprylic acid, capric acid and other flavor compounds. Among them, alkanes accounted for 11.52%, ketones accounted for 84.07%, acids accounted for 3.34%, and other flavor compounds accounted for 1.07%. In unfermented cream samples, the main flavor effecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com