Preparation method and application of strong-flavor peptide in soy sauce

A thick-flavored peptide and soy sauce technology, which is applied in the field of food biology to achieve the effect of high flavor intensity and thick flavor enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

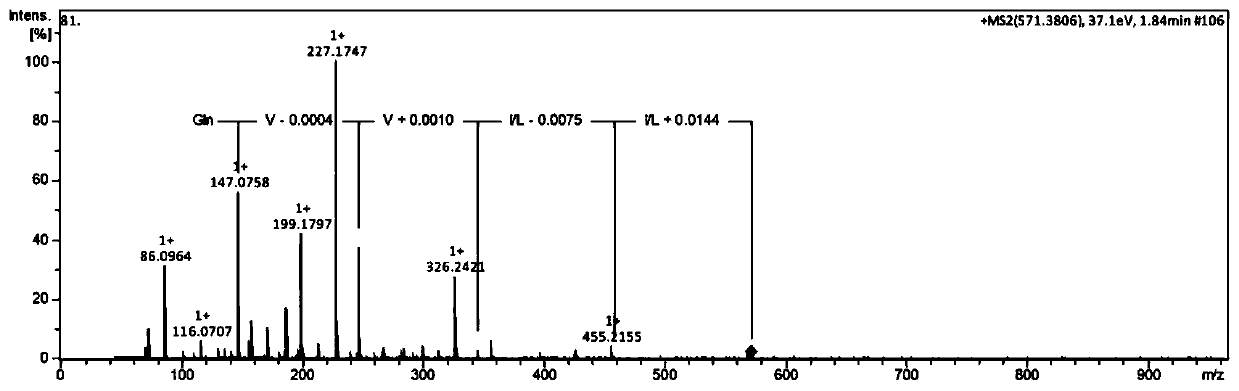

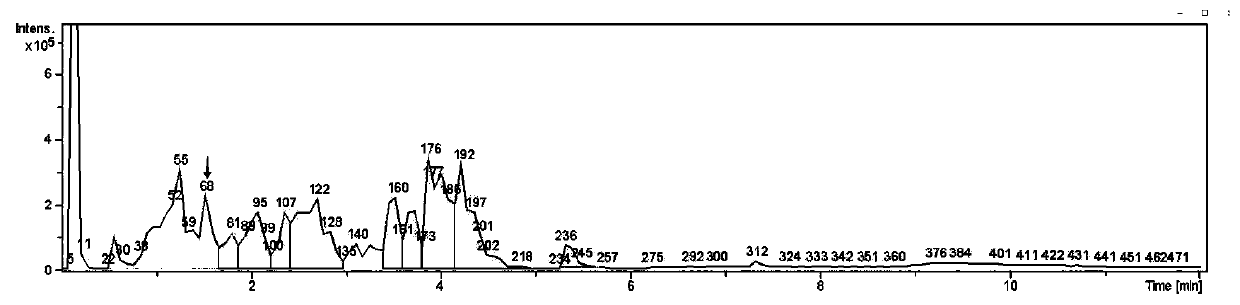

Image

Examples

Embodiment 1

[0031] (1) Soybean meal and wheat flour are mixed at a weight ratio of 1:1, extruded and expanded at 140°C, cooled and inoculated with 0.02% (w / w) of soybean meal and wheat flour aspergillus, and the culture temperature is 28°C , the humidity is 70%, the cultivation time is 42h to make koji, and the koji is obtained;

[0032] (2) Mix Daqu with twice the amount of brine, and ferment for 60 days using the high-salt dilute soy sauce brewing method (GB18186-2000), add 0.002% (g / mL) glutaminase, continue to ferment for 30 days, heat treatment, Squeeze and filter to obtain the soy sauce stock solution.

[0033] (3) passing the soy sauce stock solution through an ultrafiltration membrane with a molecular weight of 5000Da, and getting the permeate;

[0034] (4) Pass the permeate through the Oasis MAX mixed-type anion solid-phase extraction column, sequentially use deionized water and 5% (g / 100mL) acetic acid eluent, and take the acetic acid eluent to obtain a Leu-Leu-Val-rich - Ferm...

Embodiment 2

[0038] (1) Soybean meal and wheat flour are mixed at a weight ratio of 4:1, extruded and expanded at 150°C, cooled and inoculated with 0.2% (w / w) of soybean meal and wheat flour aspergillus, and the culture temperature is 30°C , the humidity is 90%, the culture time is 72h to make koji, and the koji is obtained;

[0039] (2) Mix Daqu with 3 times salt water, and ferment for 90 days using the high-salt dilute soy sauce brewing method (GB18186-2000), add 0.05% (g / mL) glutaminase, continue to ferment for 20 days, heat treatment, Squeeze and filter to obtain the soy sauce stock solution.

[0040] (3) passing the soy sauce stock solution through an ultrafiltration membrane with a molecular weight of 5000Da, and getting the permeate;

[0041] (4) Pass the permeate through the Oasis MAX mixed-type anion solid-phase extraction column, sequentially use deionized water and 8% (g / 100mL) acetic acid eluent, and take the acetic acid eluent to obtain a Leu-Leu-Val-rich - Fermentation prod...

Embodiment 3

[0043] (1) Soybean meal and wheat flour are mixed at a weight ratio of 2:1, extruded and extruded at 160°C, cooled and then inoculated with 0.02% (w / w) of soybean meal and wheat flour aspergillus, and the culture temperature is 32°C , the humidity is 80%, the cultivation time is 42h to make koji, and the koji is obtained;

[0044] (2) Mix Daqu with 2.5 times of salt water, and ferment for 80 days using the high-salt dilute soy sauce brewing method (GB18186-2000), add 0.01% (g / mL) glutaminase, continue to ferment for 10 days, heat treatment, Squeeze and filter to obtain the soy sauce stock solution.

[0045] (3) passing the soy sauce stock solution through an ultrafiltration membrane with a molecular weight of 5000Da, and getting the permeate;

[0046] (4) Pass the permeate through the Oasis MAX mixed-type anion solid-phase extraction column, sequentially use deionized water and 10% (g / 100mL) acetic acid eluent, and take the acetic acid eluent to obtain a Leu-Leu-Val-rich - F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com