Plum liquid essence for cigarettes and production process thereof

A production process and liquid technology, applied in the directions of essential oils/spices, tobacco, application, etc., can solve the problems of easy oxidation of liquid flavors, reduced flavor intensity of liquid flavors, difficulty in achieving flavor and aroma of cigarettes, etc. The degree of fit and adequacy, the improvement of stability and odor intensity, the effect of improving odor intensity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

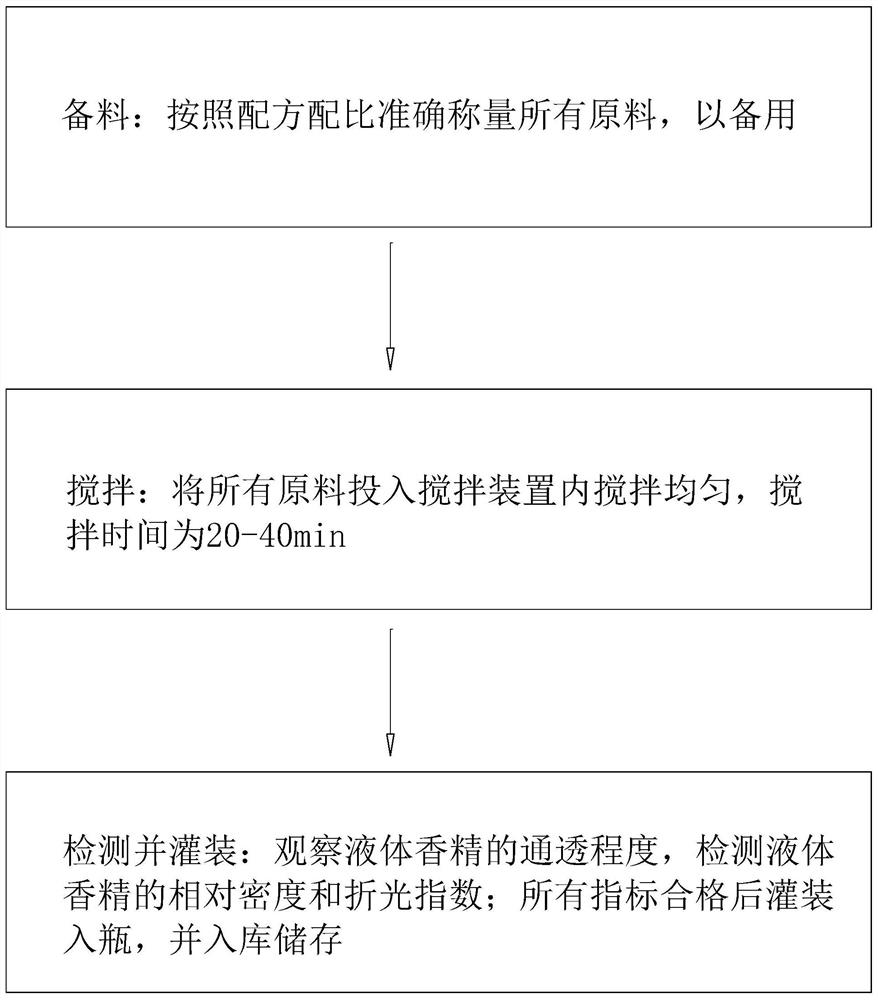

[0038] Reference figure 1

[0039] A production process of plum liquid flavor for tobacco includes the following steps:

[0040] Preparation: Accurately weigh 50kg of ethanol, 2kg of plum juice, 2kg of propylene glycol, 3kg of deionized water, 2kg of dihydrostragalic acid, 2kg of butylhydroxyanisole, 0.5kg of monoglyceride fatty acid ester and 2,4-hexadienoic acid according to the formula ratio 1kg for spare.

[0041] Use a food pulverizer to crush the sour plum extract into several pieces, screen out pieces of equal size, and accurately weigh 5 kg of sour plum extract. Filter the jujube powder, cocoa powder and red jujube powder with a sieve mesh of 80 mesh respectively, and accurately weigh 1kg of the jujube powder, 1kg cocoa powder and 1kg jujube powder after the sieving, for use.

[0042] Stirring: Pour all the raw materials into the stirred tank in turn, raise the temperature in the stirred tank to 50°C, set the stirring speed of the stirred tank to 1600r / min, turn on the stirr...

Embodiment 2

[0047] Reference figure 1

[0048] A production process of plum liquid flavor for tobacco includes the following steps:

[0049] Material preparation: Accurately weigh 70kg of ethanol, 6kg of plum juice, 8kg of propylene glycol, 9kg of deionized water, 8kg of dihydrostragalic acid, 6kg of butylhydroxyanisole, 1.5kg of monoglyceride fatty acid ester and 2,4-hexadienoic acid according to the formula ratio 5kg for spare.

[0050] Use a food pulverizer to break the sour plum extract into several pieces, screen out pieces of equal size, and accurately weigh 12 kg of sour plum extract. Filter the wild jujube powder, cocoa powder and red jujube powder respectively with a filter mesh of 120 mesh, and accurately weigh 5 kg of the wild jujube powder, 3 kg of cocoa powder and 5 kg of the red jujube powder after sieving, for use.

[0051] Stirring: Pour all the raw materials into the stirred tank in turn, raise the temperature in the stirred tank to 80°C, set the stirring speed of the stirred t...

Embodiment 3

[0056] Reference figure 1

[0057] A production process of plum liquid flavor for tobacco includes the following steps:

[0058] Preparation: Accurately weigh 60kg of ethanol, 4kg of plum juice, 5kg of propylene glycol, 6kg of deionized water, 5kg of dihydrostragalic acid, 4kg of butylated hydroxyanisole, 1kg of monoglyceride fatty acid ester and 3kg of 2,4-hexadienoic acid according to the formula ratio. To spare.

[0059] Use a food pulverizer to crush the plum extract into several pieces, screen out pieces of equal size, and accurately weigh 8 kg of plum extract. Filter the jujube powder, cocoa powder and red jujube powder with a filter mesh of 100 mesh, and accurately weigh 3kg of the jujube powder, 2kg of cocoa powder and 3kg of the jujube powder after sieving, for use.

[0060] Stirring: Pour all the raw materials into the stirred tank in turn, raise the temperature in the stirred tank to 65°C, set the stirring speed of the stirred tank to 2200r / min, turn on the stirred tank a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com