Preparation method for high rich flavor chicken powder, and application

A technology for chicken powder and chicken, which is applied in climate change adaptation, food science, etc., to achieve the effect of simple preparation method, improved umami and thick taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

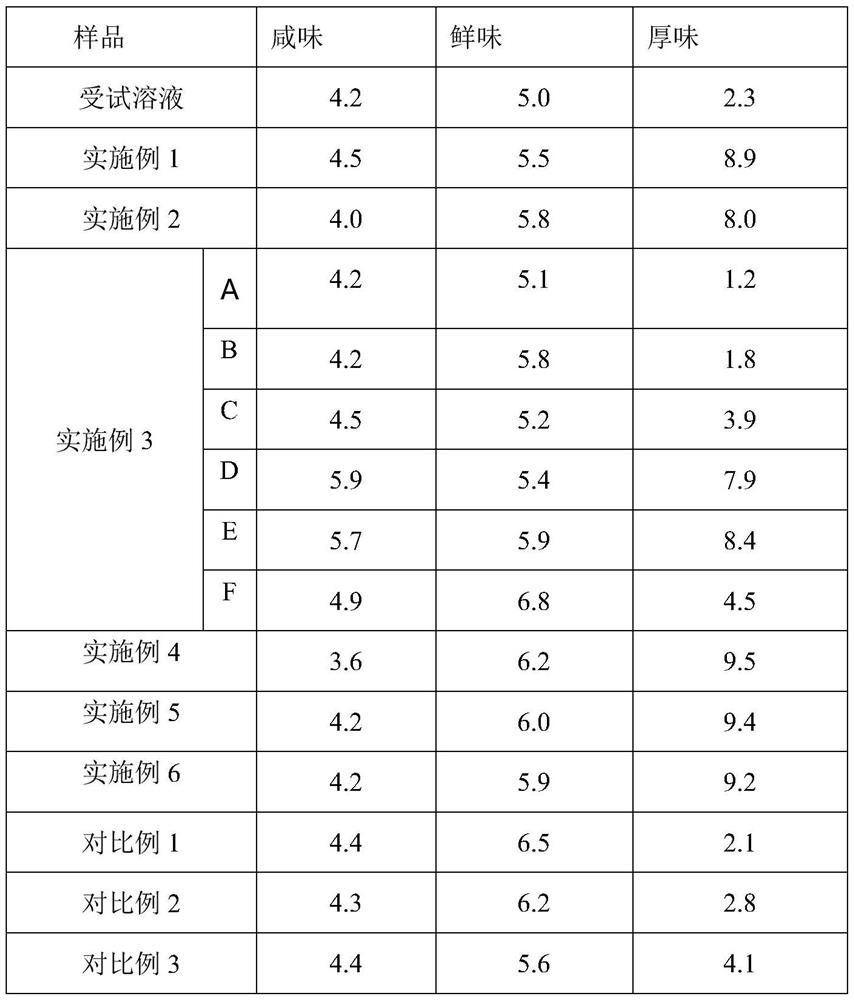

Examples

Embodiment 1

[0032] (1) Take 100g chicken breast meat as raw material, pass through a meat grinder, add 1kg deionized water, add 0.01g Aspergillus oryzae koji essence, add papain (Nanning Donghenghuadao Biotechnology Co., Ltd., Nanning Donghenghuadao Biotechnology Co., Ltd., The activity is 500,000 u / g) and 0.5% flavor protease (Novozymes China Co., Ltd., Flavorzyme 1000L, from Aspergillus oryzae) fermented for 20 hours at 30°C and a pH value of 6.0 to increase the degree of hydrolysis of chicken protein Reach 42.4%, keep 95 ℃ for 10min to sterilize and eliminate enzymes, obtain 1.1kg chicken fermented liquid.

[0033] (2) Centrifuge 1.1kg of chicken fermented liquid to remove the fat in the upper layer of the fermented liquid, collect the precipitate and supernatant obtained by fermentation, concentrate to about 35% solids with a rotary vacuum concentrator, and spray dry to obtain 40 g of chicken protein peptide. After determination, the moisture content of the obtained chicken protein pe...

Embodiment 2

[0036] (1) Take 10kg chicken breast meat as raw material, pass through a meat grinder, add 120kg deionized water, add 3g Aspergillus oryzae koji essence, add bromelain (Chongqing Jiaowang Natural Products Co., Ltd., vitality 100) of chicken breast meat 0.3% 10,000 u / g) and 0.3% compound protease (Novozymes China Co., Ltd., Protamex) at 35 ° C, the stirring speed is 60 rpm, and the pH value is 7.0 under the conditions of fermentation 26h, so that the degree of hydrolysis of chicken protein reaches 37.3%, Keep at 90° C. for 15 minutes to sterilize and kill enzymes to obtain 130 kg of chicken fermented liquid.

[0037] (2) 130kg of chicken fermented liquid was centrifuged to remove the fat in the upper layer of the fermented liquid, and the precipitate and supernatant obtained by fermentation were collected, concentrated to about 40% solids by a vacuum concentrator, and spray-dried to obtain 2.95 kg of chicken protein peptide powder. After determination, the moisture content of t...

Embodiment 3A

[0040](1) take 10kg chicken breast as raw material, cross meat grinder, add 120kg deionized water, add 2g Aspergillus oryzae koji essence, add 7089 (German AB enzyme preparation company) of chicken breast weight 0.2%, 0.4% trypsin ( Novozymes China Co., Ltd., PTN, with an activity of 500,000 u / g) and 0.3% Protease MSD (Japan Amano Enzyme Co., Ltd.) were fermented for different times at 37°C, with a stirring speed of 60rpm and a pH value of 6.5 Section, make the degree of hydrolysis of chicken protein reach 12.4%, keep at 90 DEG C for 15min to sterilize and eliminate enzymes, and obtain chicken fermented liquid.

[0041] (2) Remove the fat in the upper layer of the fermentation broth from the chicken fermentation broth, collect the fermented precipitate and supernatant, concentrate with a vacuum concentrator to about 40% solids, and spray dry to obtain chicken protein peptide powder. It is determined that the moisture content of the obtained chicken protein peptide powder is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com