Preparation method of composite beef seasoning

A production method and seasoning technology are applied in the production field of compound beef seasoning, which can solve the problems of dark color of finished products, inconspicuous product flavor and other problems, and achieve improved bioavailability, increased soluble calcium content, high nutrition and high bioavailability rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

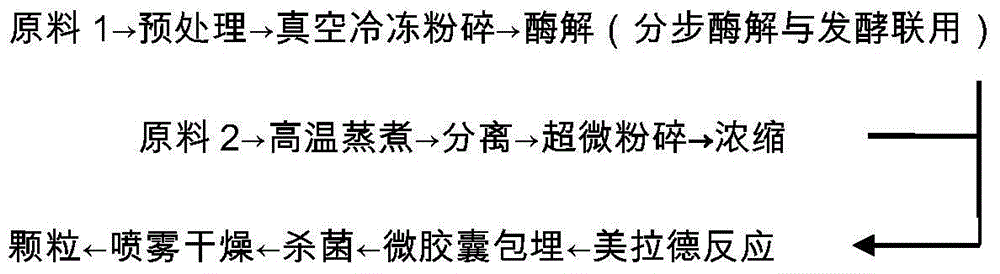

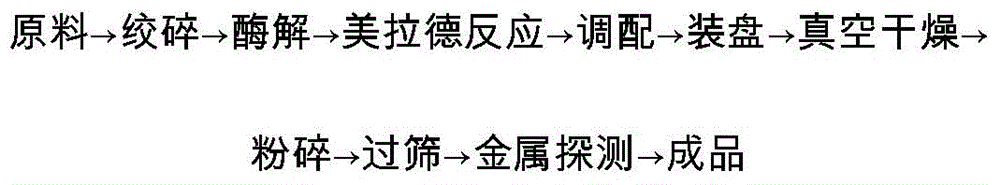

Method used

Image

Examples

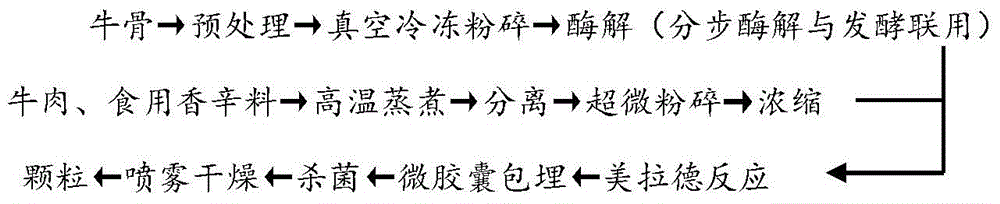

Embodiment 1

[0047] (1) Raw material handling

[0048] Take 1kg each of fresh beef bones and beef (purchased in the market), wash them in clean water, and then blanch them at 70°C for 3 minutes, take them out and soak them in cold water to remove surface dirt, cut the beef into pieces, coarsely chop the beef bones, and drain for later use.

[0049] The bovine bone was placed in a YB-FD-18 vacuum freeze dryer (Shanghai Yibei Industrial Co., Ltd.) for 24 hours, and then it was pulverized by an XDW-6BI laboratory-specific low-temperature ultrafine pulverizer (Jinan Dawei Machinery Co., Ltd.) to prepare an average grain size. 0.1-0.5mm in diameter bone meal, 0.9kg of bone meal was obtained.

[0050] Take 100g dried mint leaves, 100g dried onions, 50g dried green onions, 50g ginger, 80g tangerine peel, 30g edible salt, 20g monosodium glutamate, 40g dried peppers, 20g white sugar, 20g star anise, 20g cinnamon, 20g peppercorns, 20g fennel , cloves 20g, tea leaves 20g. It is made into powder by ...

Embodiment 2

[0069] (1) Raw material handling

[0070] Take 1kg of fresh beef bones and 1.5kg of beef (commercially purchased), wash them in clean water, and then blanch them at 70°C for 3 minutes, take them out and soak them in cold water to remove surface dirt, cut the beef into pieces, coarsely chop the beef bones, and drain for later use .

[0071] The bovine bone was placed in a YB-FD-18 vacuum freeze dryer (Shanghai Yibei Industrial Co., Ltd.) for 24 hours, and then it was pulverized by an XDW-6BI laboratory-specific low-temperature ultrafine pulverizer (Jinan Dawei Machinery Co., Ltd.) to prepare an average grain size. 0.1-0.5mm in diameter bone meal, 0.9kg of bone meal was obtained.

[0072] Take 150g dried mint leaves, 150g dried onions, 70g dried green onions, 70g ginger, 80g tangerine peel, 40g edible salt, 20g monosodium glutamate, 30g dried peppers, 20g white sugar, 20g star anise, 20g cinnamon, 20g peppercorns, 20g fennel , cloves 20g, tea leaves 20g. It is made into powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com