A method for regulating the quality of horseradish sauce by fermentation

A technology of horseradish sauce and quality, which is applied in the direction of the function of food ingredients, bacteria used in food preparation, food ingredients as antimicrobial preservation, etc., can solve the problems affecting the flavor intensity of horseradish sauce, and achieve shelf life growth and improvement Nutritional quality, flavor improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

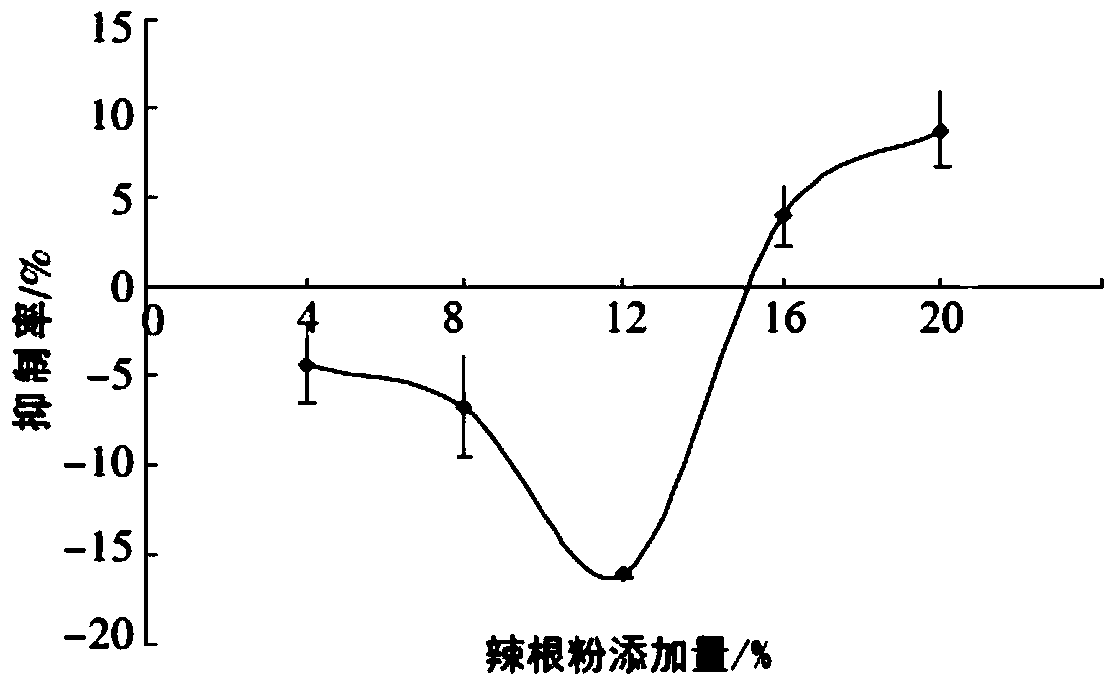

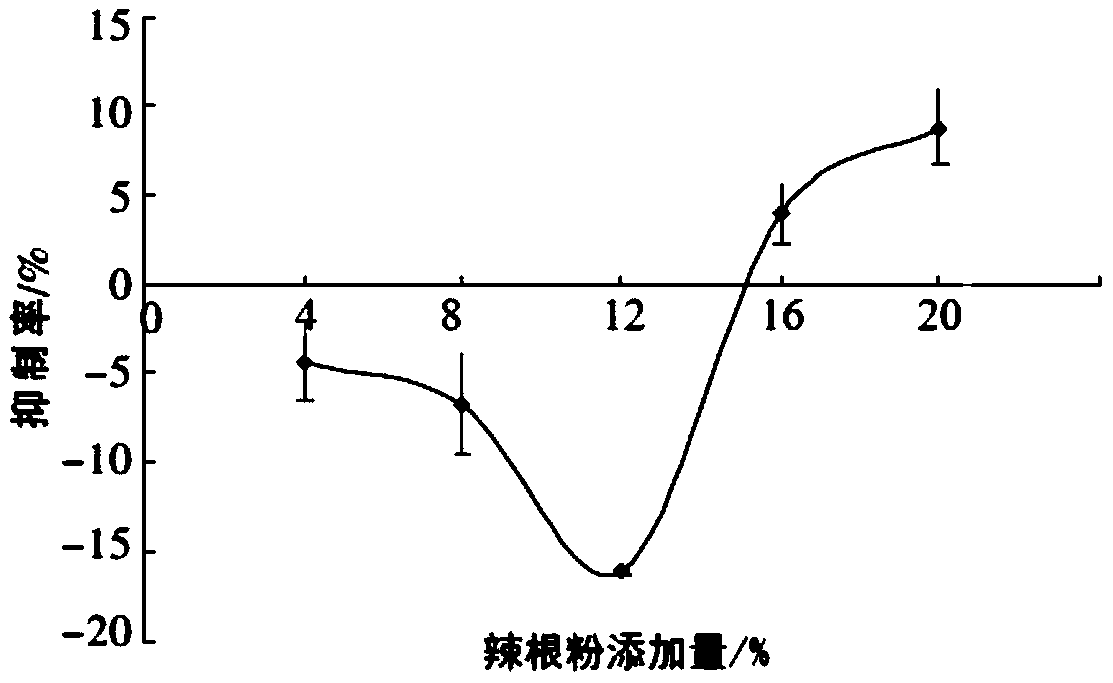

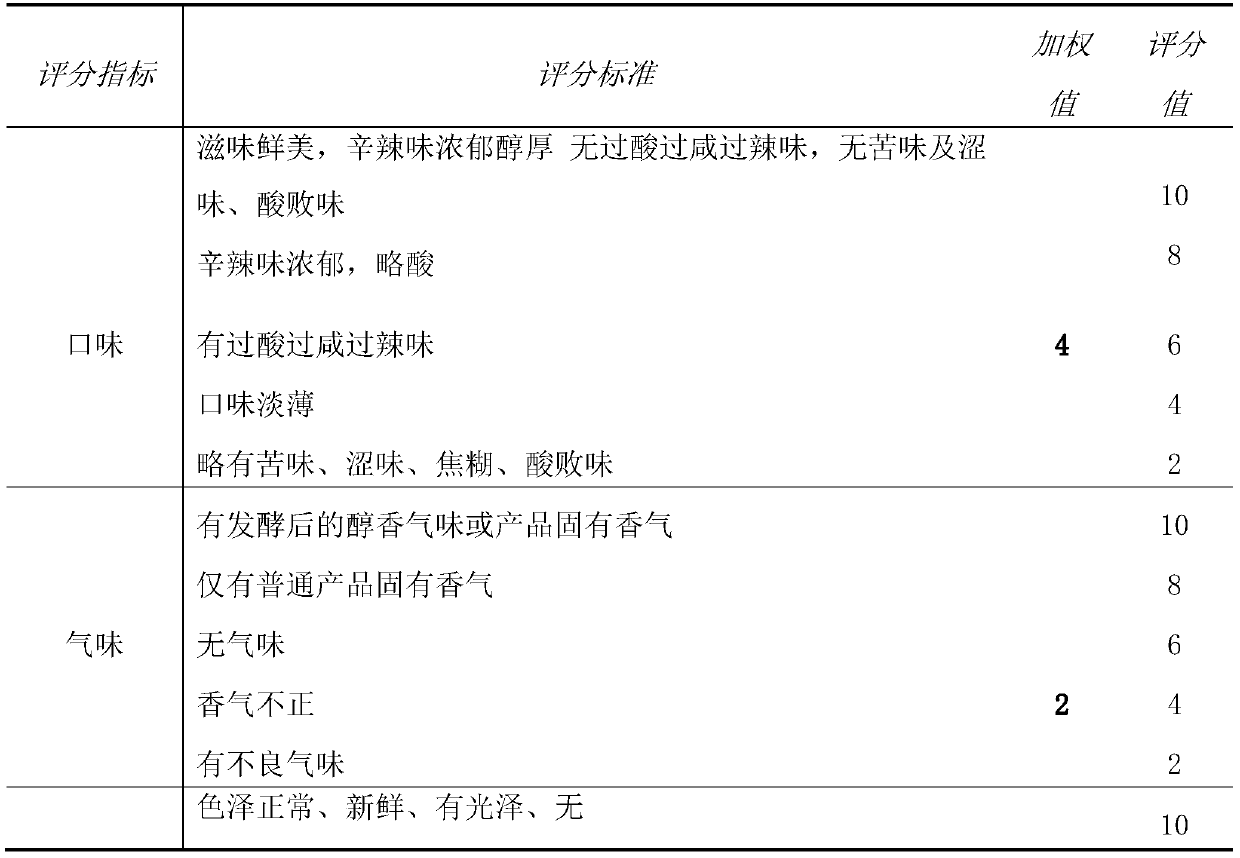

Embodiment 1

[0034]The total mass of raw materials is recorded as 100%. In a vacuum emulsifier, dissolve and mix an aqueous phase composed of 21% horseradish powder from Jiangsu, 0.5% xanthan gum, 5% sucrose, etc. at room temperature; The oil phase composed of soybean oil, 0.2% glyceryl stearate and the like is dissolved and mixed evenly under heating; then the dissolved water phase and oil phase substances are mixed and stirred evenly. In the ingredients mixed in the emulsifier, add 1.5% of Lactobacillus plantarum and Lactobacillus brevis activated sludge isolated from pickled mustard respectively, and the number of live bacteria of Lactobacillus plantarum and Lactobacillus brevis activated sludge is >10 9 cfu / g, fermented at 37°C for 20 hours. Weigh about 1.0g of sample into a 25mL small beaker, add 10mL of distilled water, stir well with a glass rod, let it stand for 10-15min, measure the pH value of the supernatant, and repeat 3 times to obtain the average value. When the pH of the sa...

Embodiment 2

[0044] The total mass of raw materials is recorded as 100%. In a vacuum emulsifier, the aqueous phase composed of 20% horseradish powder from Jiangsu, 0.5% xanthan gum, 4% sucrose, etc. is dissolved and mixed at room temperature; then 5.5% The oil phase composed of soybean oil, 0.25% glyceryl stearate and the like is dissolved and mixed evenly under heating; then the dissolved water phase and oil phase substances are mixed and stirred evenly. In the ingredients mixed in the emulsifier, add 1.3% of Lactobacillus plantarum and Lactobacillus brevis activated sludge isolated from pickled mustard respectively, and the number of live bacteria of Lactobacillus plantarum and Lactobacillus brevis activated sludge is >10 9 cfu / g, fermented at 30°C for 21 hours. Weigh about 1.0g of sample into a 25mL small beaker, add 10mL of distilled water, stir well with a glass rod, let it stand for 10-15min, measure the pH value of the supernatant, and repeat 3 times to obtain the average value. Wh...

Embodiment 3

[0053] The total mass of raw materials is recorded as 100%. In a vacuum emulsifier, dissolve and mix an aqueous phase composed of 22% horseradish powder from Jiangsu, 0.5% xanthan gum, 4% sucrose, etc. at room temperature; The oil phase composed of soybean oil, 0.2% glyceryl stearate and the like is dissolved and mixed evenly under heating; then the dissolved water phase and oil phase substances are mixed and stirred evenly. In the ingredients mixed in the emulsifier, add 1.5% of Lactobacillus plantarum and Lactobacillus brevis activated sludge isolated from pickled mustard respectively, and the number of live bacteria of Lactobacillus plantarum and Lactobacillus brevis activated sludge is >10 9 cfu / g, fermented at 37°C for 20 hours. Weigh about 1.0g of sample into a 25mL small beaker, add 10mL of distilled water, stir well with a glass rod, let it stand for 10-15min, measure the pH value of the supernatant, and repeat 3 times to obtain the average value. When the pH of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com