Electrical heat pan

A technology of electric heating pot and outer pot, which is applied in the direction of preventing overflow, can solve the problems of poor temperature sensing effect, and achieve the effect of easy assembly, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

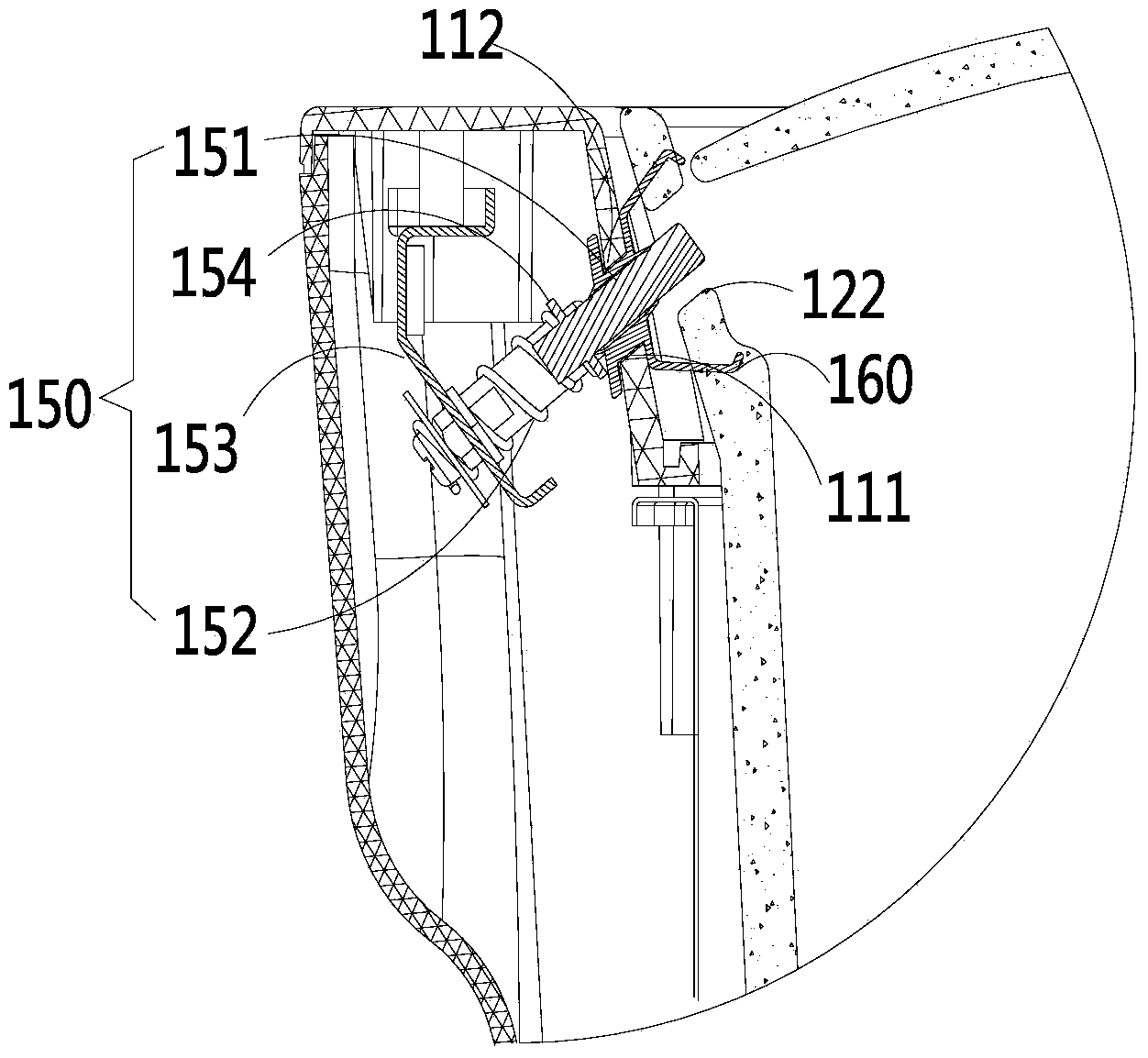

[0023] In order to make the purpose, technical solutions and advantages of the present invention clearer, below in conjunction with embodiment and accompanying drawing, further describe the present invention in detail:

[0024] In order to overcome the defects of complex structure, cumbersome assembly and high cost caused by installing the temperature-sensing component on the upper cover in the prior art, the present invention provides an electric heating pot, which can effectively solve the above-mentioned problems and has good temperature-sensing effect The advantages.

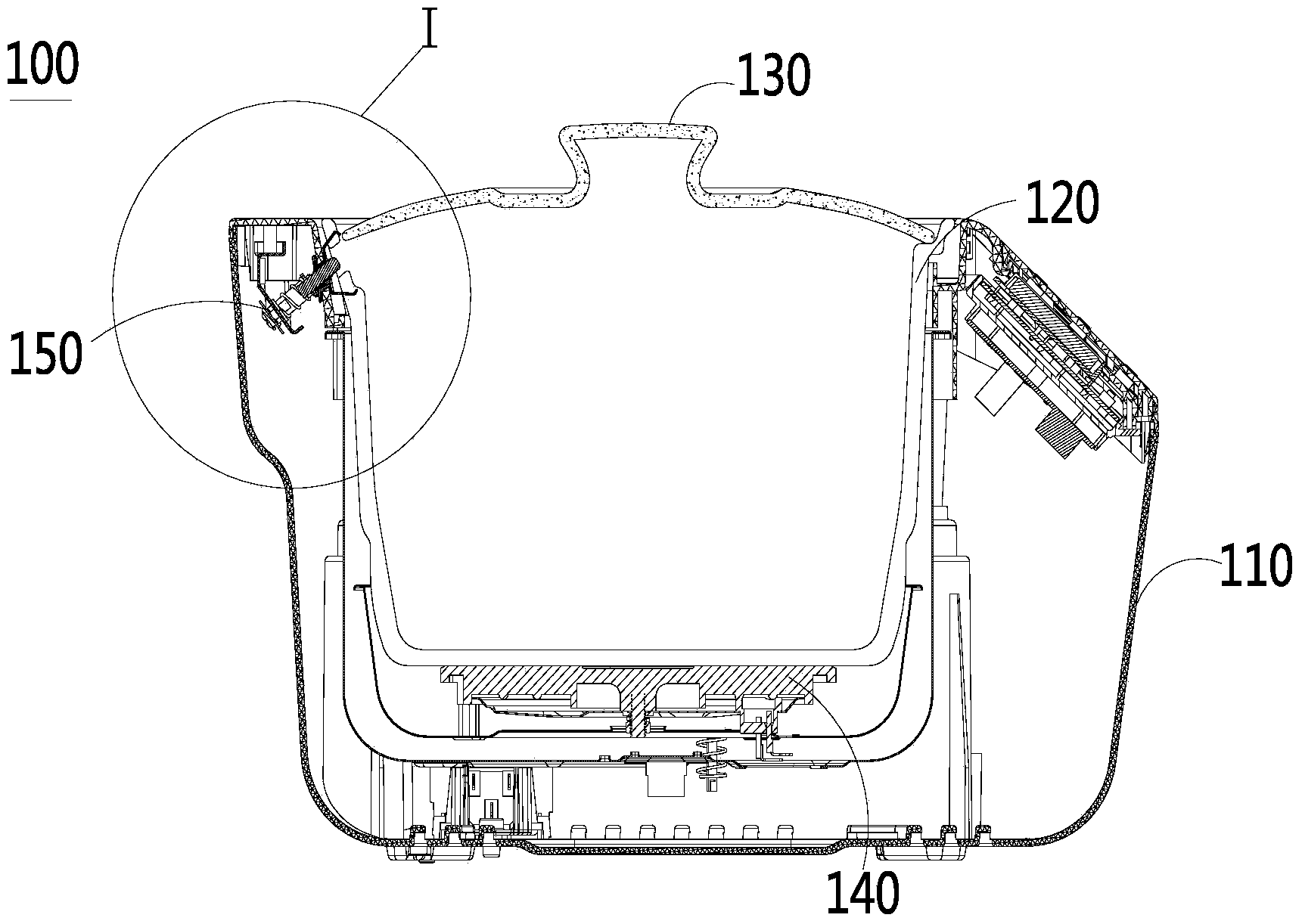

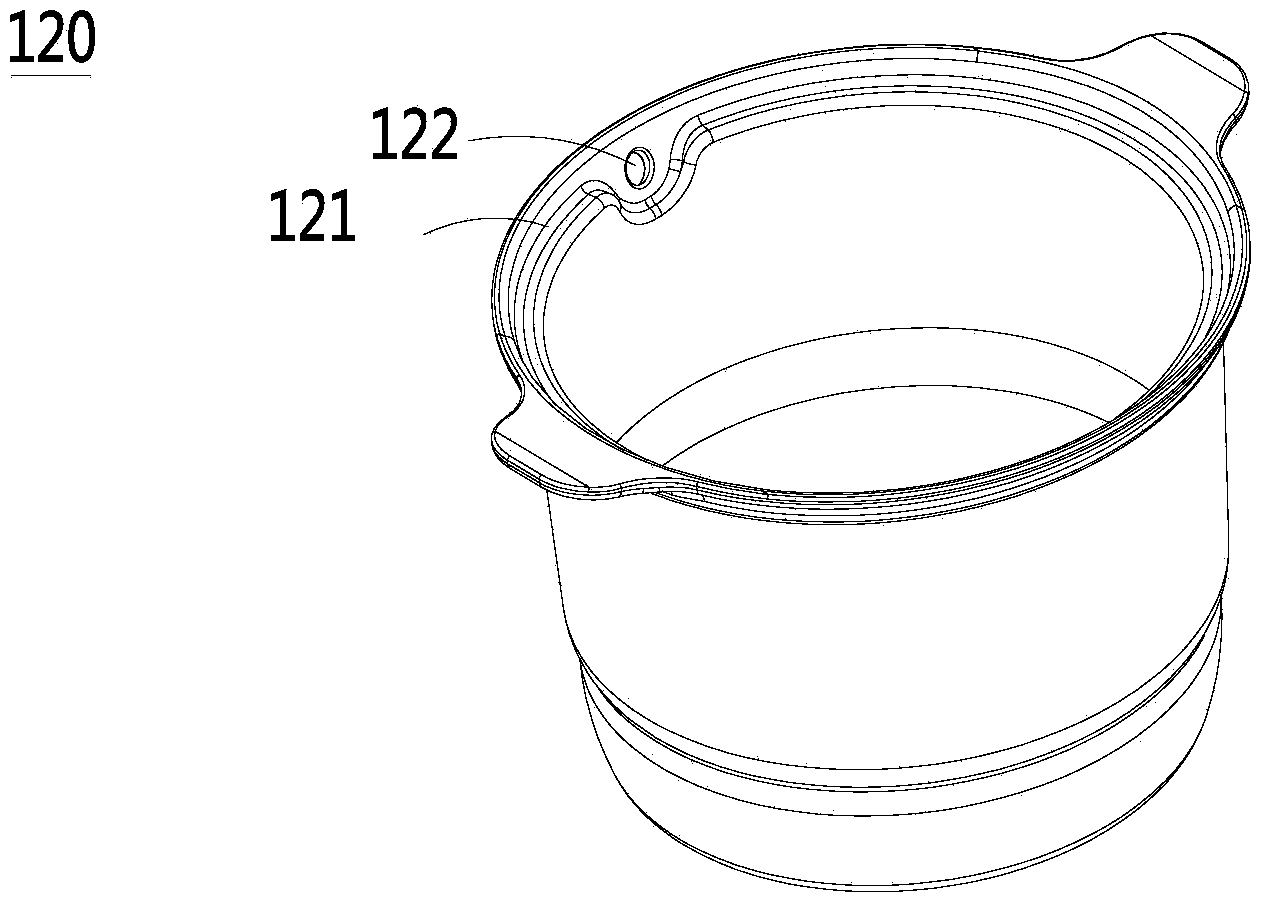

[0025] like Figure 1~Figure 2 As shown, the electric heating pot 100 of this embodiment includes an outer pot 110, an inner pot 120, an upper cover 130, and a heating device 140, wherein the inner pot 120 is placed inside the outer pot 120, and the upper cover 130 can at least cover the inner pot 120 , so that the inner pot 120 forms a relatively airtight space to speed up the cooking speed of food.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com