Flat plate type photocatalytic reaction device

A photocatalytic reaction and flat-plate technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., to achieve the effects of increasing residence time, improving satisfaction and happiness, and high economic and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the drawings and embodiments.

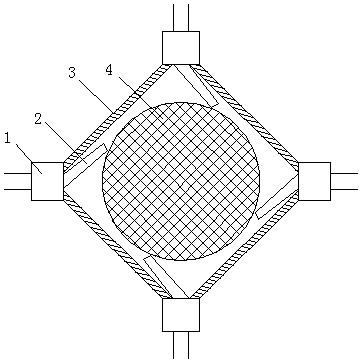

[0030] Such as figure 1 , As shown in 2, a flat-plate photocatalytic reaction device includes an airflow injection port 2, a reactor cavity 3, and a photocatalytic film 4.

[0031] The reactor cavity 3 is a quadrilateral cavity. The four corners of the quadrilateral cavity are provided with air inlets 1 respectively. The photocatalytic film 4 is installed in the middle of the reactor cavity 3, and the air inlet 1 and the photocatalytic film 4 are An airflow injection port 2 is arranged in between. One end of the airflow injection port 2 is connected with the air inlet 1 and the other end is tangentially connected with the outer circle of the photocatalytic film 4. The front and rear ends of the reactor cavity 3 are respectively provided with air outlets 5.

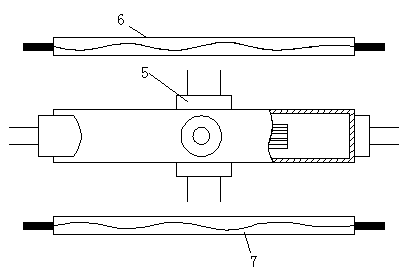

[0032] Such as figure 1 As shown, an ultraviolet lamp tube 6 and a fluorescent tube 7 are respectively arranged abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com