A detection and sorting device for steel balls

A sorting device, steel ball technology, applied in sorting, optical testing of defects/defects, etc., can solve the problems of large impact of camera shooting, uneven intensity, errors, etc., to achieve consistent light intensity, uniform light intensity, error The effect of low detection rate and missed detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

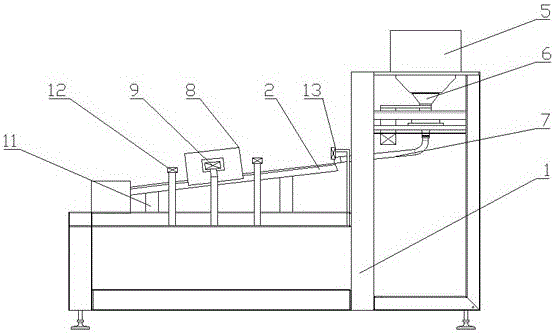

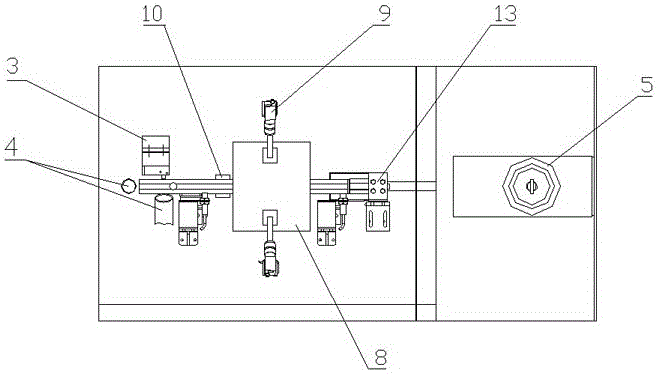

[0022] As shown in the figure: a detection and sorting device for steel balls, including a frame 1, a feeding mechanism, an unfolding mechanism 2, a blocking mechanism 13, a detection mechanism, a sorting mechanism 3 and a receiving mechanism. The feeding mechanism includes a material storage box 5, a lower hopper 6 and a lower material pipe 7, the material storage box 5 is fixedly arranged on the frame 1, and the upper and lower ends of the material storage box 5 are open. Material box 5 is made up of the cylinder of top and the funnel of bottom, and the cylinder of material storage box 5 is provided with fixed bar, and the upper end of material stirring bar is fixedly connected with fixed bar, and the lower end of material stirring bar is connected from the funnel of material storage box 5. The part extends into the lower hopper 6. The lower hopper 6 is arranged at the lower end of the storage box 5. The lower hopper 6 can be rotated through the gears on its periphery, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com