Cold heading die for engine bearing cover fastener

An engine and cold heading technology, which is applied to manufacturing tools, forging/pressing/hammering machinery, forging/pressing/hammer devices, etc. Bearing cap bolt head defects and other problems, to achieve the effect of improving production and processing efficiency, material content stability and saturation, and reducing improvement processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

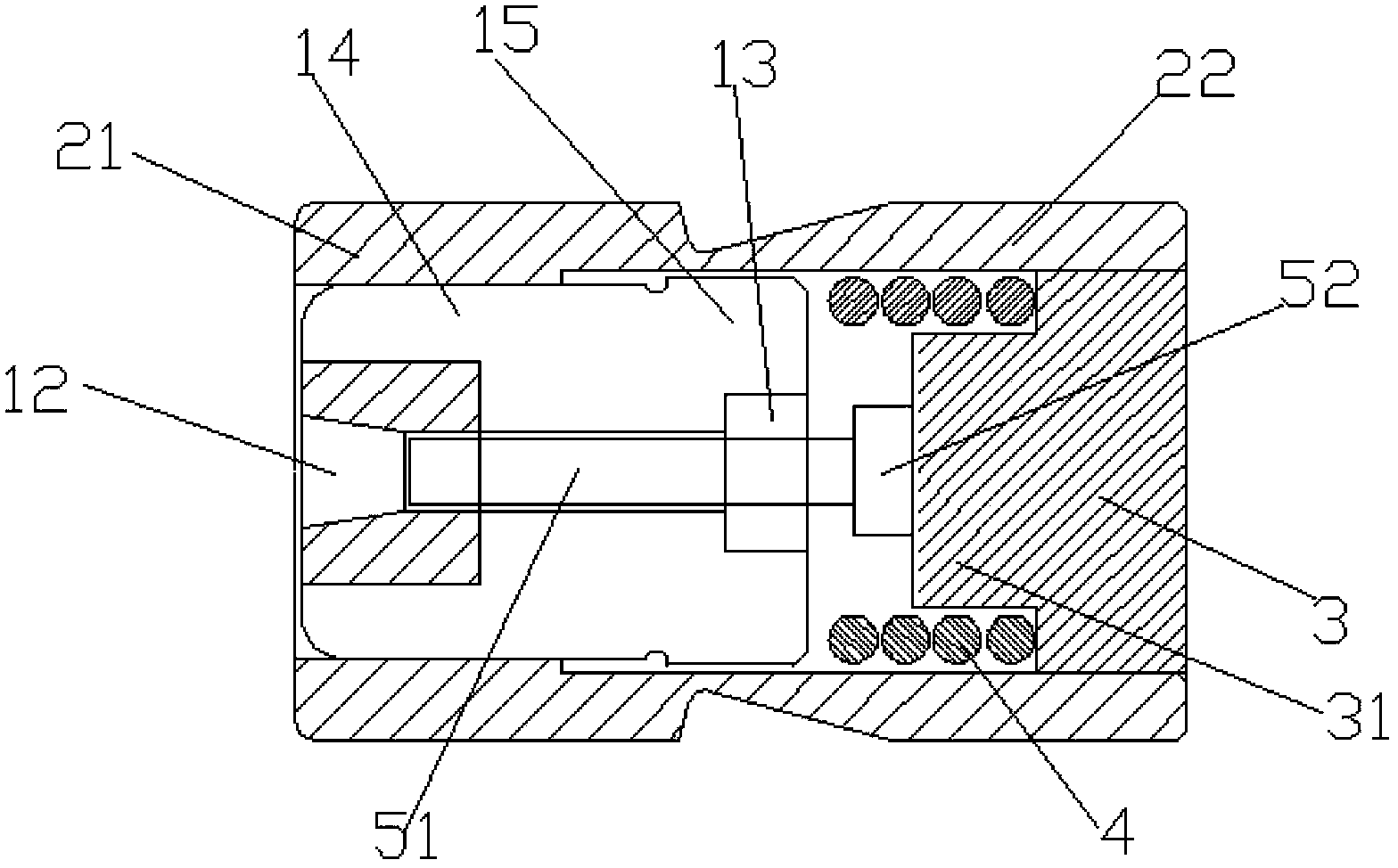

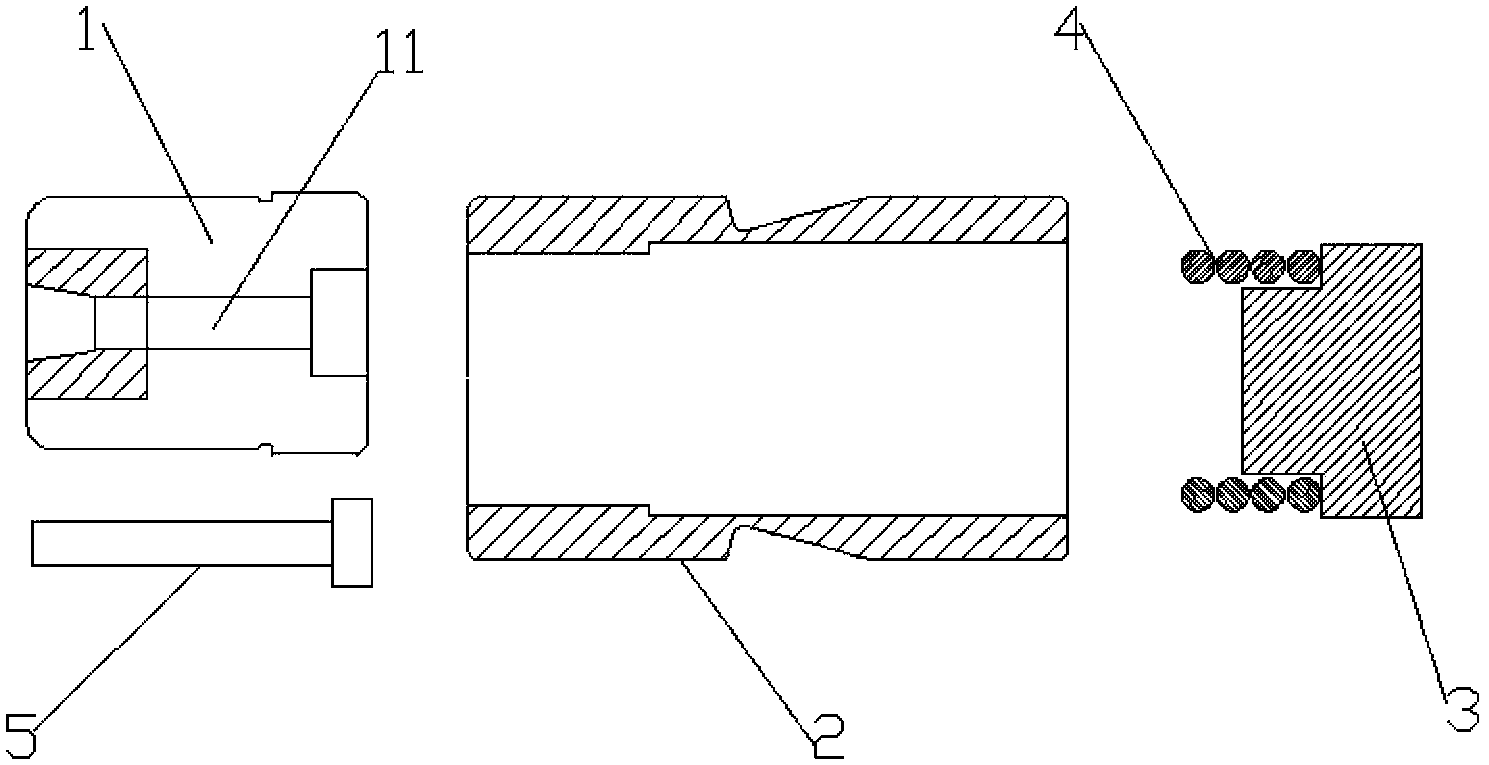

[0015] Such as figure 1 and figure 2 As shown, a cold heading die for fastening engine bearing caps is used for cold heading processing engine bearing cap bolt heads. The cold heading dies include a cylindrical floating die 1 and a hollow cylindrical casing 2; A through hole 11, one end of the through hole forms a cavity 12 for the head of the cold heading bolt, and the other end of the through hole forms a limiting groove 13. The limiting groove is used in conjunction with the thimble that ejects the product after cold heading, thereby limiting the distance that the thimble moves to the cavity end. The floating die is divided into a die forming part 14 and a die coupling part 15 along the axial outer side, and the die coupling part is located at the end facing away from the cavity; the axial inner side of the casing is divided into a casing coupling part 21 and a casing limiting part 22 , the casing coupling part is sleeved outside the die forming part, and the casing limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com