Regenerated corundum spinel unfired ladle brick

A corundum spinel and corundum technology, applied in the field of regenerated corundum spinel non-fired ladle bricks, can solve the problems of high production cost and poor performance, achieve low pollution of molten steel, improve performance and reduce waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better explain the present invention, the main content of the present invention will be further clarified below in conjunction with specific embodiments, but the content of the present invention is not limited to the following embodiments.

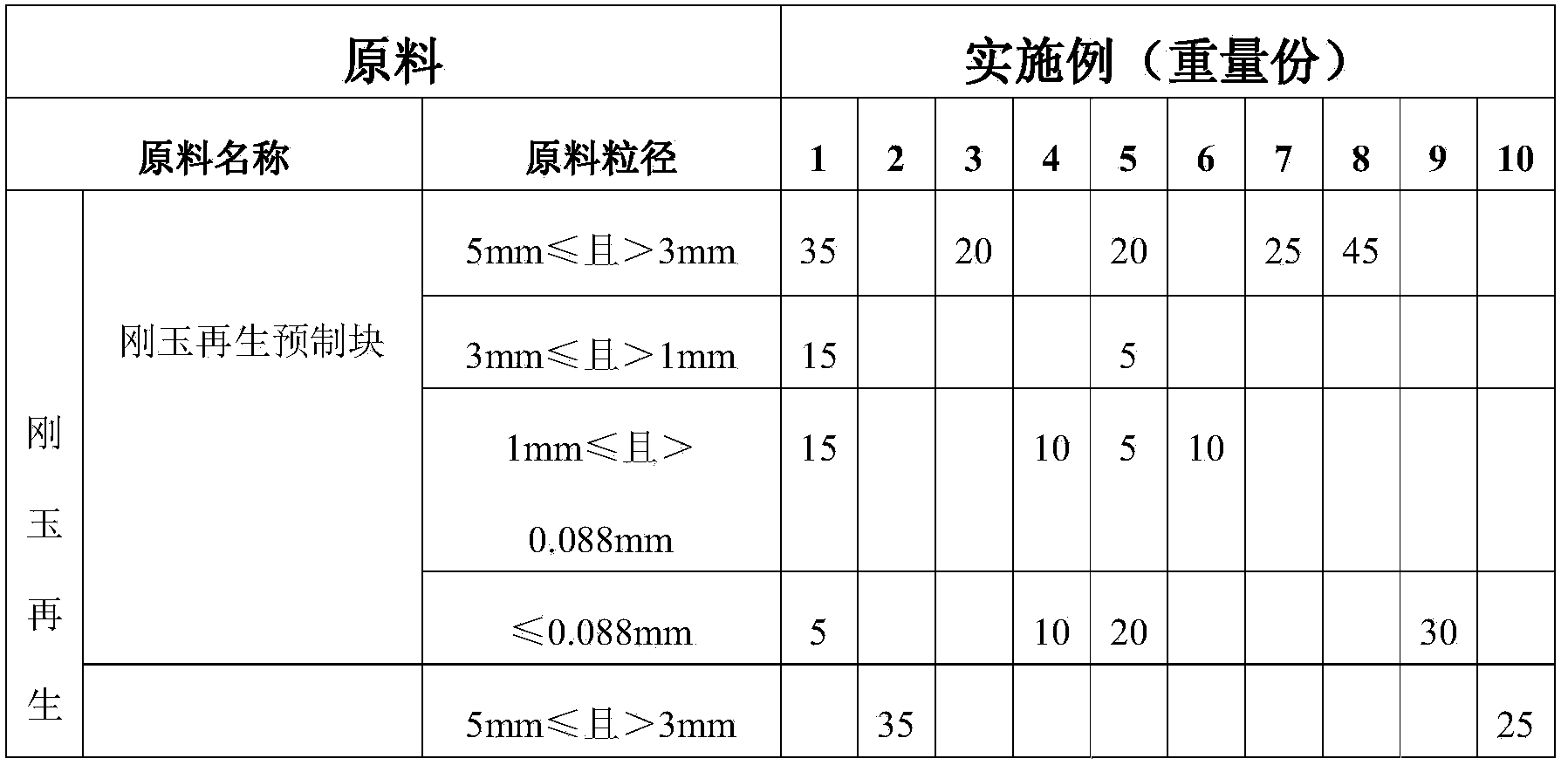

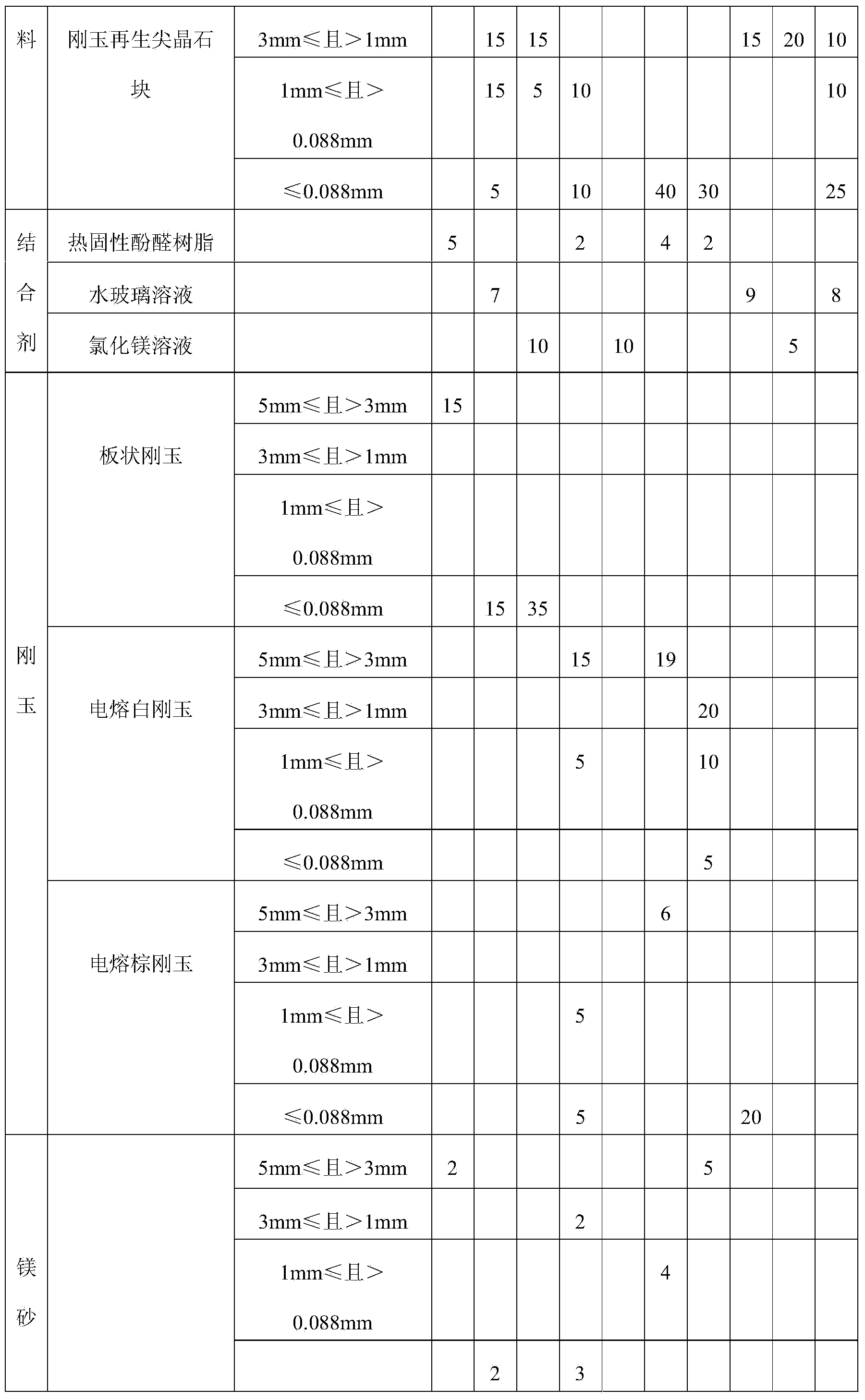

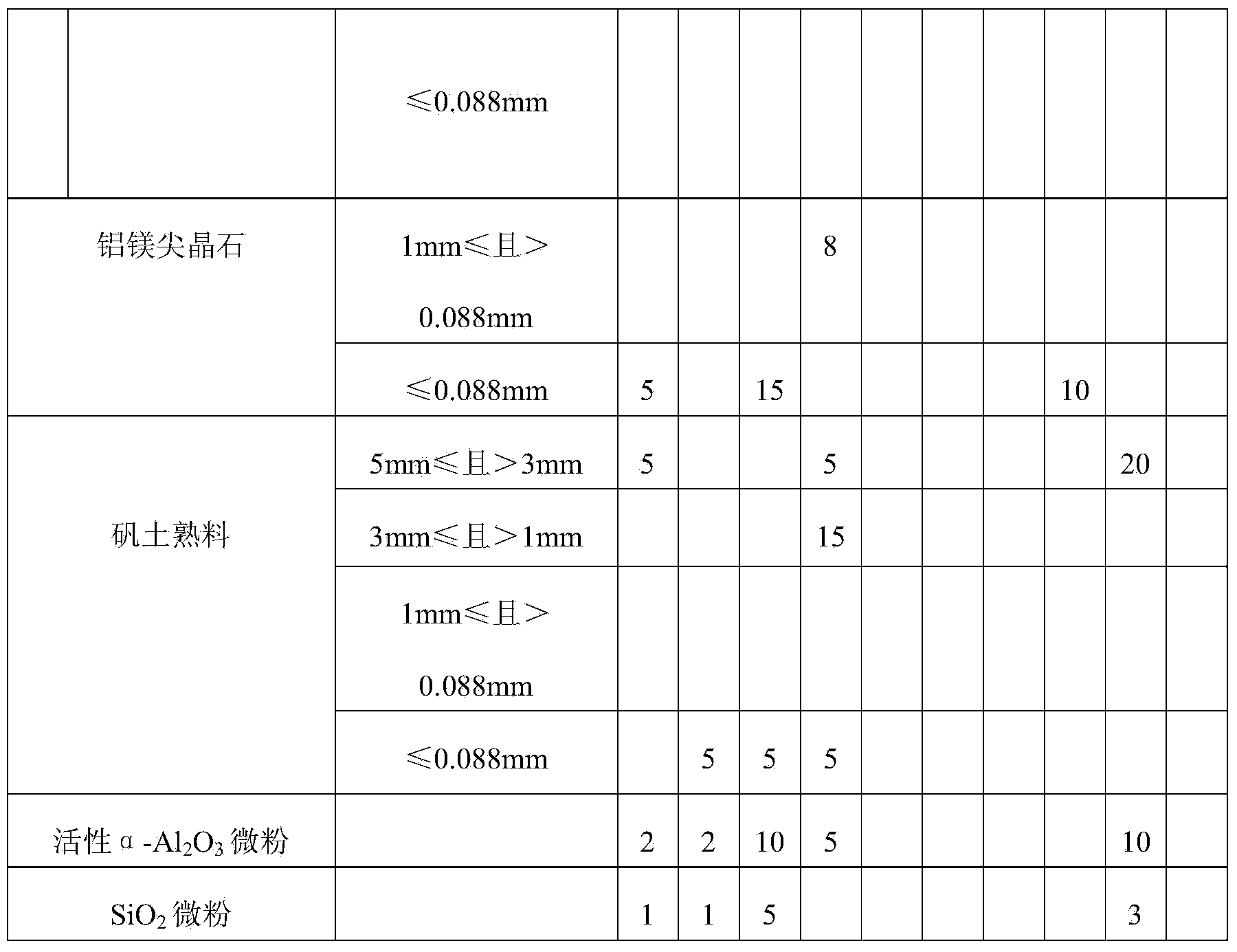

[0043] Table 2 below is the raw material combination ratio table of recycled corundum spinel non-fired ladle bricks

[0044] Table 2

[0045]

[0046]

[0047]

[0048] The preparation method of recycled corundum spinel non-fired ladle brick includes the following steps:

[0049] 1) The raw material components of the steel-clad bricks are weighed in parts by weight ratio, and reserved for use;

[0050] 2) The weighed raw materials are mixed and milled by a milling machine, and then put into a brick press for forming, heat-treated at 150-250℃ for 12-36h, and finally selected, inspected, packaged, and put into storage to obtain recycled corundum tips Spar does not burn ladle bricks.

[0051] 1. Raw material source:

[0052] 1. Corund...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com