A kind of polyacrylonitrile preoxidation treatment device and method

A technology of pre-oxidation treatment and polyacrylonitrile, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of carbon fiber quality reduction, achieve the effect of improving quality and avoiding man-made damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

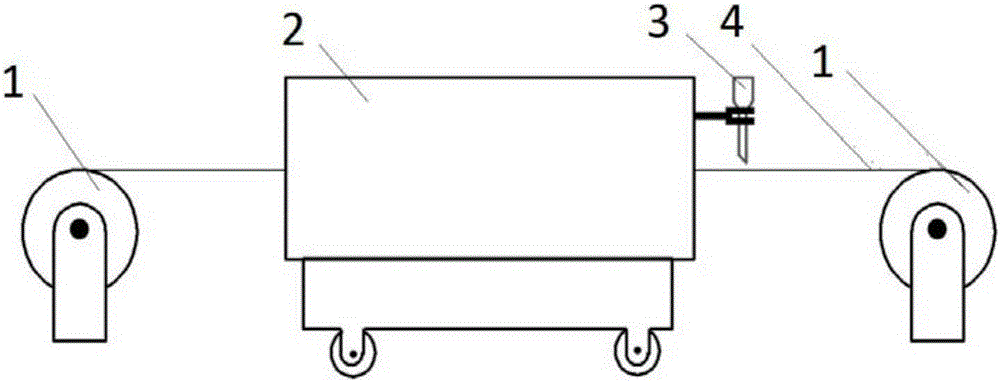

[0025] Preparations: follow figure 1 The polyacrylonitrile preoxidation treatment device assembled as shown; figure 1 Among them, 1 is a power traction mechanism, 2 is a microwave heating furnace, 3 is a sand-holding funnel, and 4 is polyacrylonitrile fiber.

[0026] Pre-oxidation treatment work:

[0027] (1) Turn on the microwave heating furnace 2 and set the heating temperature of the microwave heating furnace 2 to 200°C;

[0028] (2) Open the microwave heating furnace 2 to heat, move the microwave heating furnace 2 horizontally and open the sand-holding funnel 3, release the hydrogen peroxide solution in the sand-holding funnel 3 to drip the polyacrylonitrile fiber 4, and control the titration speed and The moving speed of microwave heating furnace 2 makes titration length just identical with the length of microwave heating furnace, and then reversely removes polyacrylonitrile fiber 4, and the whole process time of step (2) is controlled at about 50min;

[0029] (3) Rais...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that in step (3), the temperature in the furnace is set to 290°C.

Embodiment 3

[0037] The difference between this embodiment and Embodiments 1 and 2 is that the entire process time of step (2) is controlled within 60 minutes.

[0038] Except above embodiment, because the physical reaction of pre-oxidation treatment is carried out between 180~200 ℃, so the maximum temperature of step (1) heating can be set as 180~200 ℃; In the reaction, so it can be extended to 35 ~ 40min.

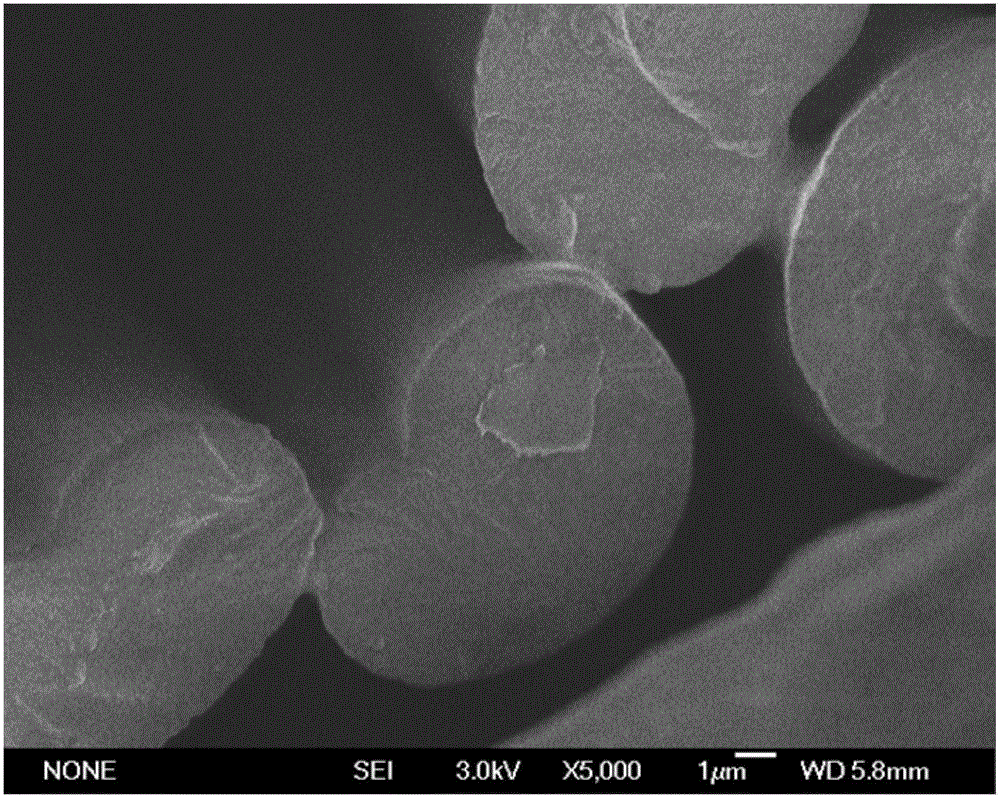

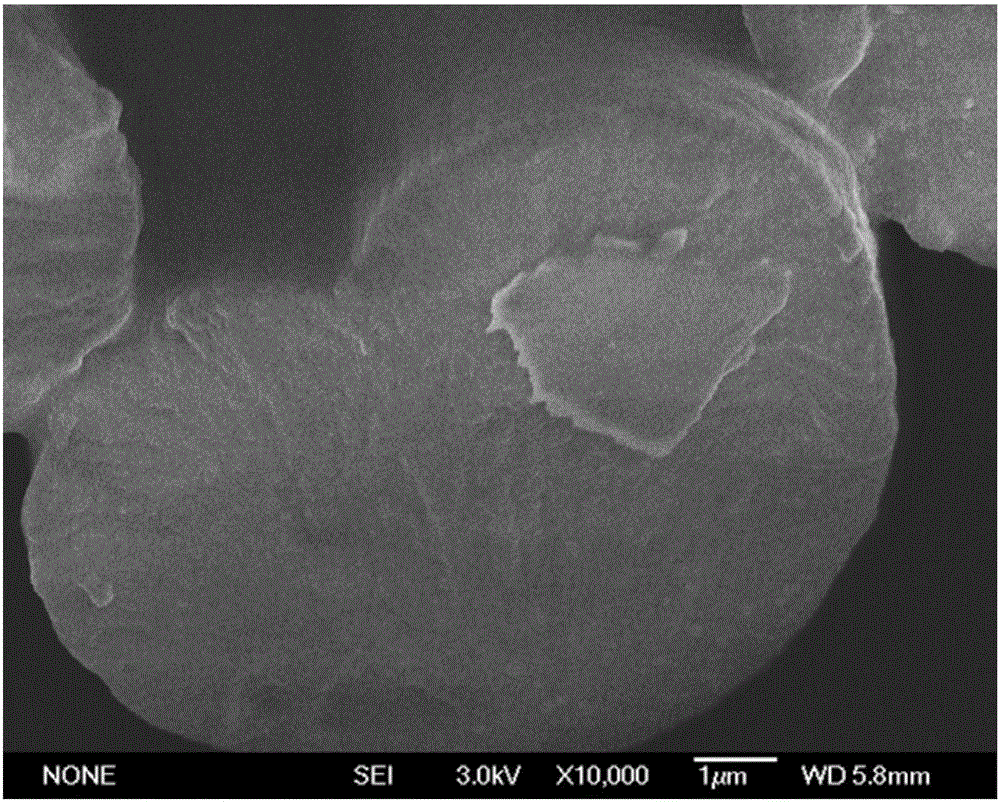

[0039] The result that embodiment 1 to embodiment 3 obtains carries out scanning electron microscope test (see Figure 2 to Figure 5 ), it was found that the polyacrylonitrile pre-oxidized wire obtained by the method of the present invention can hardly observe the skin-core structure, which proves that the method of the present invention can reduce the skin-core effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com