Polyacrylonitrile-based carbon fiber and stabilization method thereof

A polyacrylonitrile-based carbon fiber and polyacrylonitrile-based technology, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve problems such as affecting the performance of carbon fiber products, reduce the skin-core effect, improve mechanical properties, and improve thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0046] A polyacrylonitrile-based fiber precursor, specifically an acrylonitrile-itaconic acid copolymer fiber precursor, the preparation method is as follows:

[0047] (1) Dissolve itaconic acid monomer (IA), azobisisobutyronitrile (AIBN) and acrylonitrile monomer (AN) in dimethyl sulfoxide (DMSO), the sum of the concentrations of the two monomers is 5.71mmol / mL, the molar weight of AIBN is 0.2% of the total molar weight of the two monomers, and the molar ratio of acrylonitrile to itaconic acid is 98:2. into pure water, the product is precipitated and purified; the product is washed and dried to obtain an acrylonitrile-itaconic acid copolymer with a molar percentage of acrylonitrile-based structural units of 98%;

[0048] (2) wet spinning the acrylonitrile-itaconic acid copolymer obtained in step (1) to obtain the acrylonitrile-itaconic acid copolymer fiber precursor.

preparation example 2

[0050] A polyacrylonitrile-based fiber precursor, specifically a polyacrylonitrile fiber precursor, the preparation method is as follows:

[0051] The polyacrylonitrile fiber precursor with a weight average molecular weight of 210,000 and a molecular weight distribution of 1.5 is wet-spun to obtain the polyacrylonitrile fiber precursor.

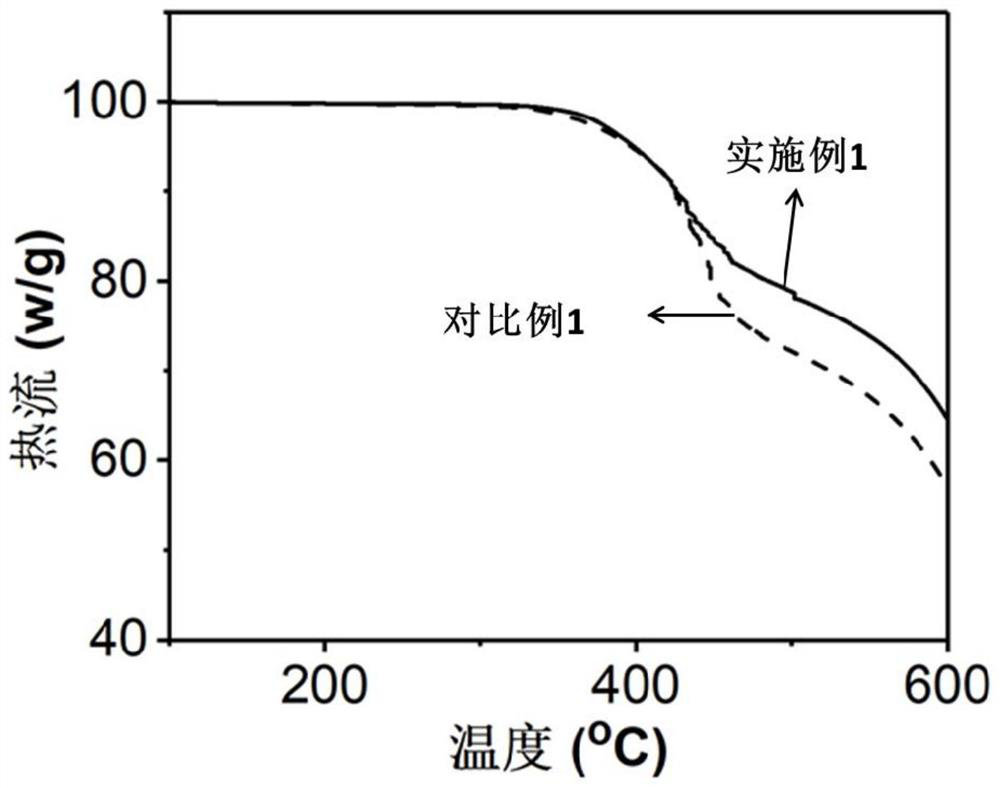

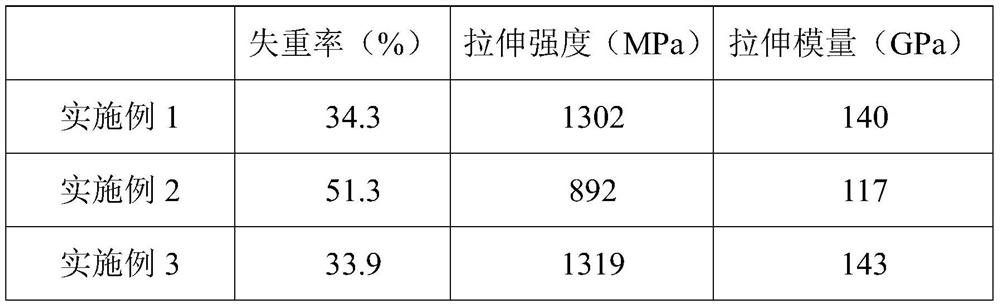

Embodiment 1

[0053] A method for stabilizing polyacrylonitrile-based carbon fibers, comprising:

[0054] (1) Low-temperature treatment: the acrylonitrile-itaconic acid copolymer fiber precursor obtained in Preparation Example 1 is placed in a tube furnace after being packed into a magnetic boat, and nitrogen is charged after vacuuming three times, and the nitrogen gas flow is 25mL / min. Keep the oxygen concentration at 0%, set the heating rate of the tube furnace at 5°C / min, heat up to 195°C and hold the temperature for 20 minutes, heat up to 205°C and hold the temperature for 20 minutes, then raise the temperature to 215°C and keep the temperature for 20 minutes, and finally raise the temperature to 220°C, the treatment time at 150-220°C is 74min;

[0055] (2) Medium temperature treatment: after low temperature treatment, keep the nitrogen gas flow at 25mL / min (oxygen concentration is 0), the heating rate is 5°C / min, heat up to 230°C and hold for 20 minutes, then raise the temperature to 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com