Fluid dynamic machine with rotating wheel piston speed change mechanism

A speed change mechanism and fluid power technology, applied in the direction of rotary piston machines, rotary piston engines, rotary or swinging piston engines, etc., can solve problems affecting the structural performance of piston compressors and piston engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

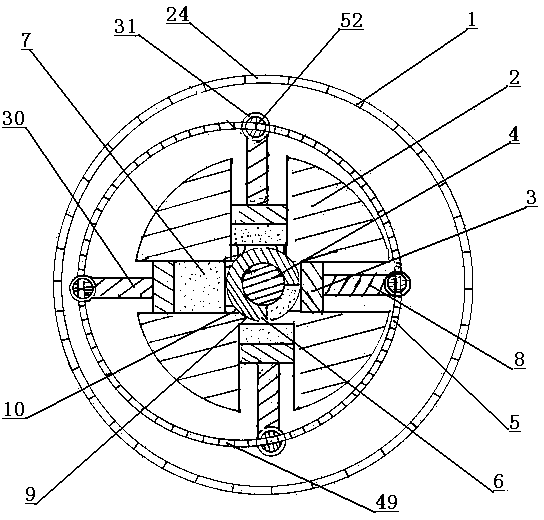

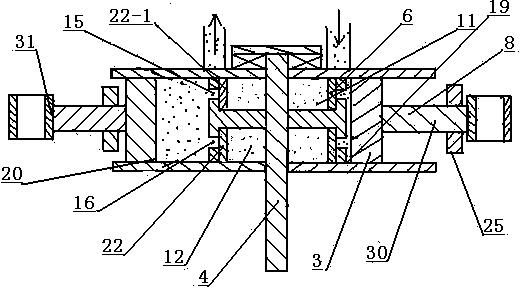

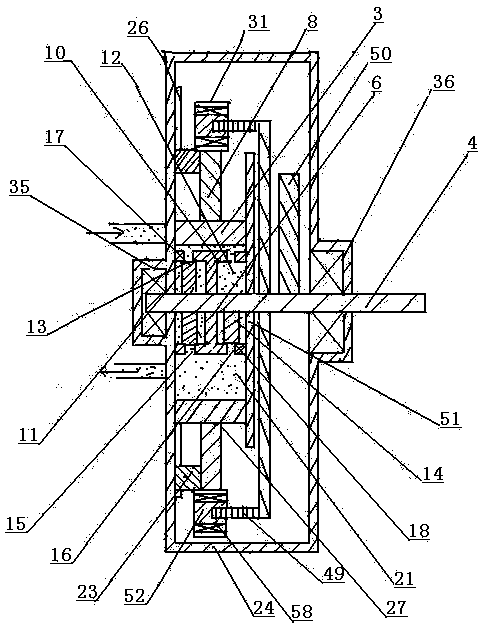

[0034] A rotary-piston mechanism 1 for a hydrodynamic machine with a rotary-piston mechanism, such as figure 1 As shown, it is composed of cylinder block 2, piston 3, sliding connecting rod 8, transmission shaft 4, wheel transmission device 5 and gas distribution device 6; cylinder block 2 is composed of annular combined cylinder head 9 and one or more than one cylinder 7 The cylinder head 10 of the cylinder 7 and the annular combined cylinder head 9 is fixedly installed with each other, and the cylinder 7 is distributed outwards with the center of the annular combined cylinder head 9 . Such as image 3 As shown, there is an air intake chamber 11 and an exhaust chamber 12 inside the annular combined cylinder head 9; the transmission shaft 4 passes through the center of the annular combined cylinder head 9, and the transmission shaft 4 is installed on the upper bearing seats on both sides of the body 24 35 and the bearing support rotation in the lower bearing block 36. Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com