A compact flexible bearing with large rotation angle range

A technology of flexible bearing and large turning angle, applied in sliding contact bearing and other directions, can solve problems such as restricting application, and achieve the effect of simplifying installation steps, compact structure and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

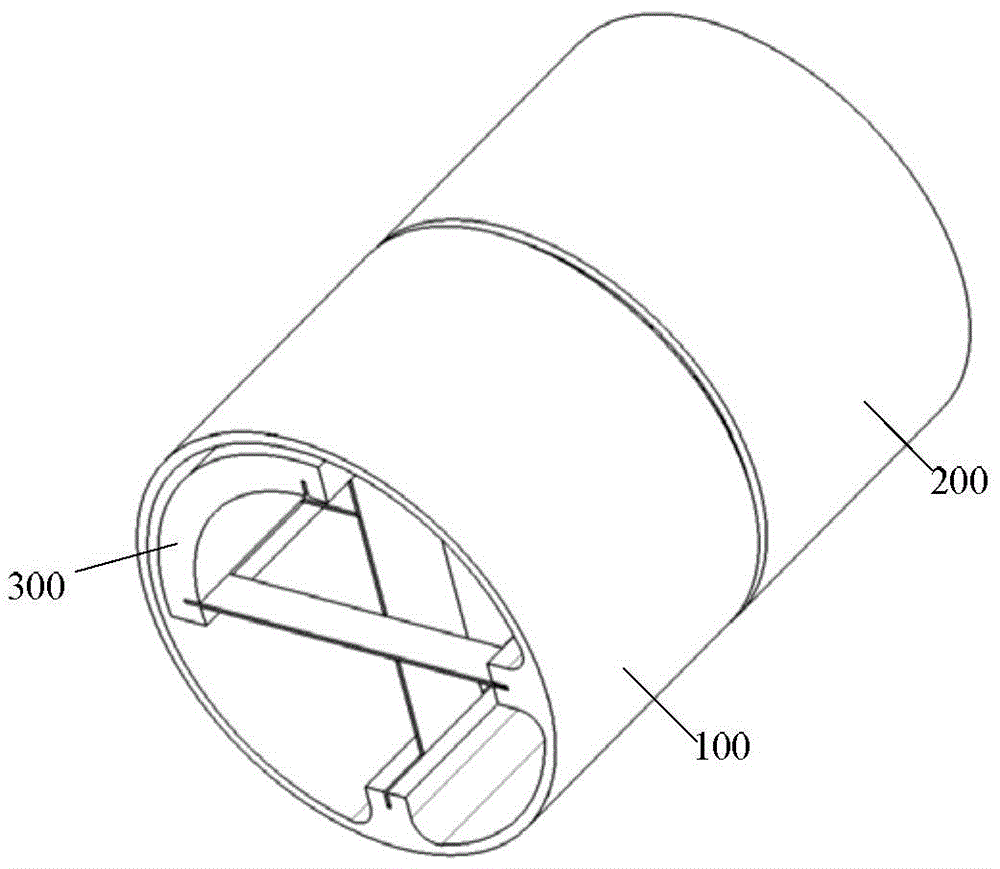

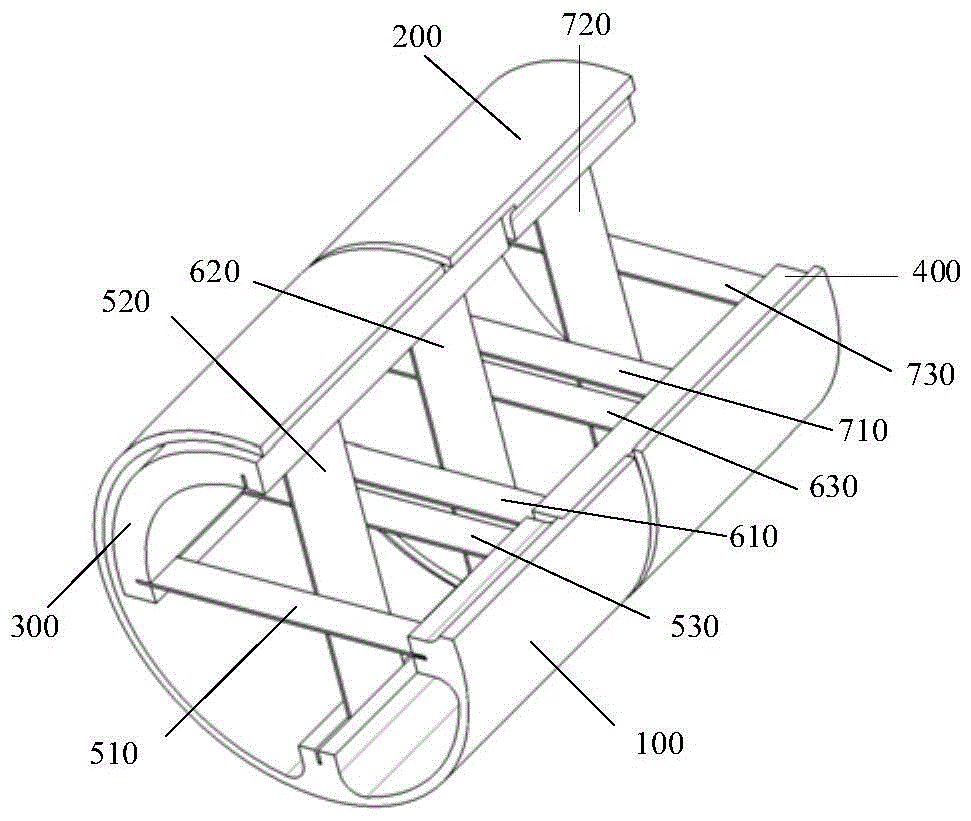

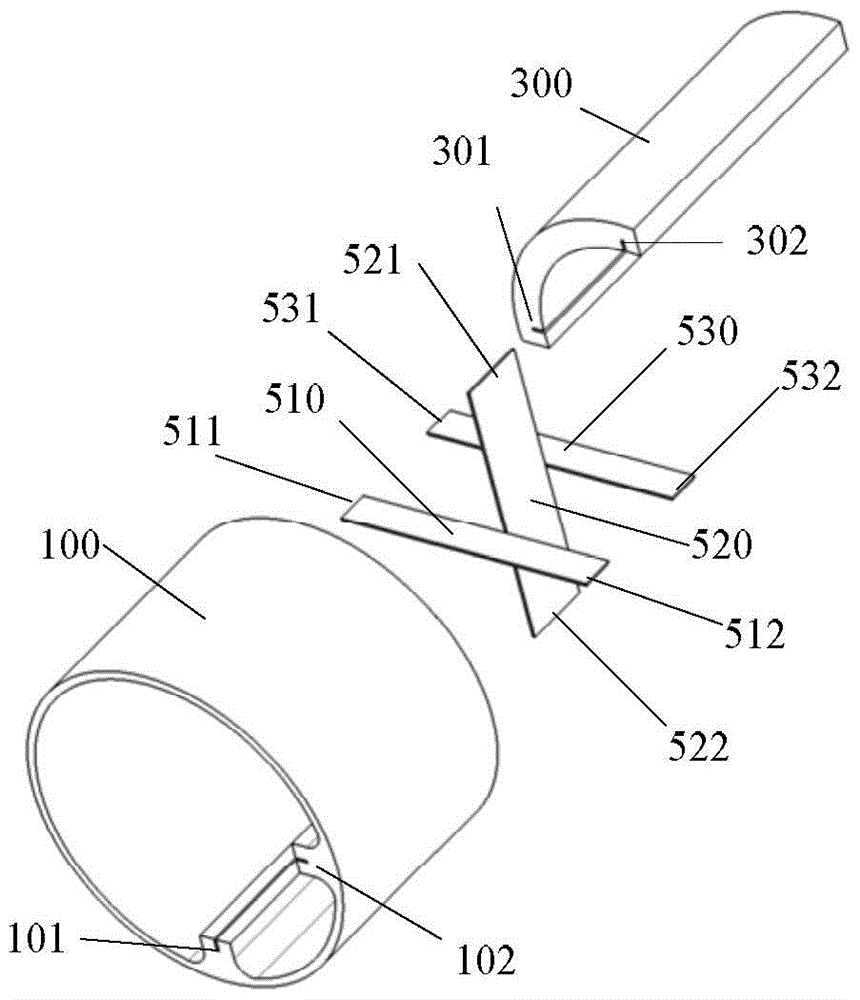

[0030] The present invention proposes a compact flexible bearing with large rotation angle range, which is characterized in that: the bearing includes two bushes with the same structure, two bearing bushes with the same structure, and three sets of spring pieces; wherein, the axes of the two bushes Overlapped, arranged at a certain distance along the axial direction, two bearing bushes are placed opposite to each other and located inside the two bushings; each group of spring sheets has the same structure, consisting of three spring sheets arranged in sequence horizontally, vertically and horizontally, and the three spring sheets There is no contact with each other along the axial direction of the bushing; the first bushing and the first bearing bush are connected together through the first set of spring pieces; the first bearing bush and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com