Barrel plating power supply system

A technology of power supply system and barrel plating, which is applied in general control system, control/regulation system, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

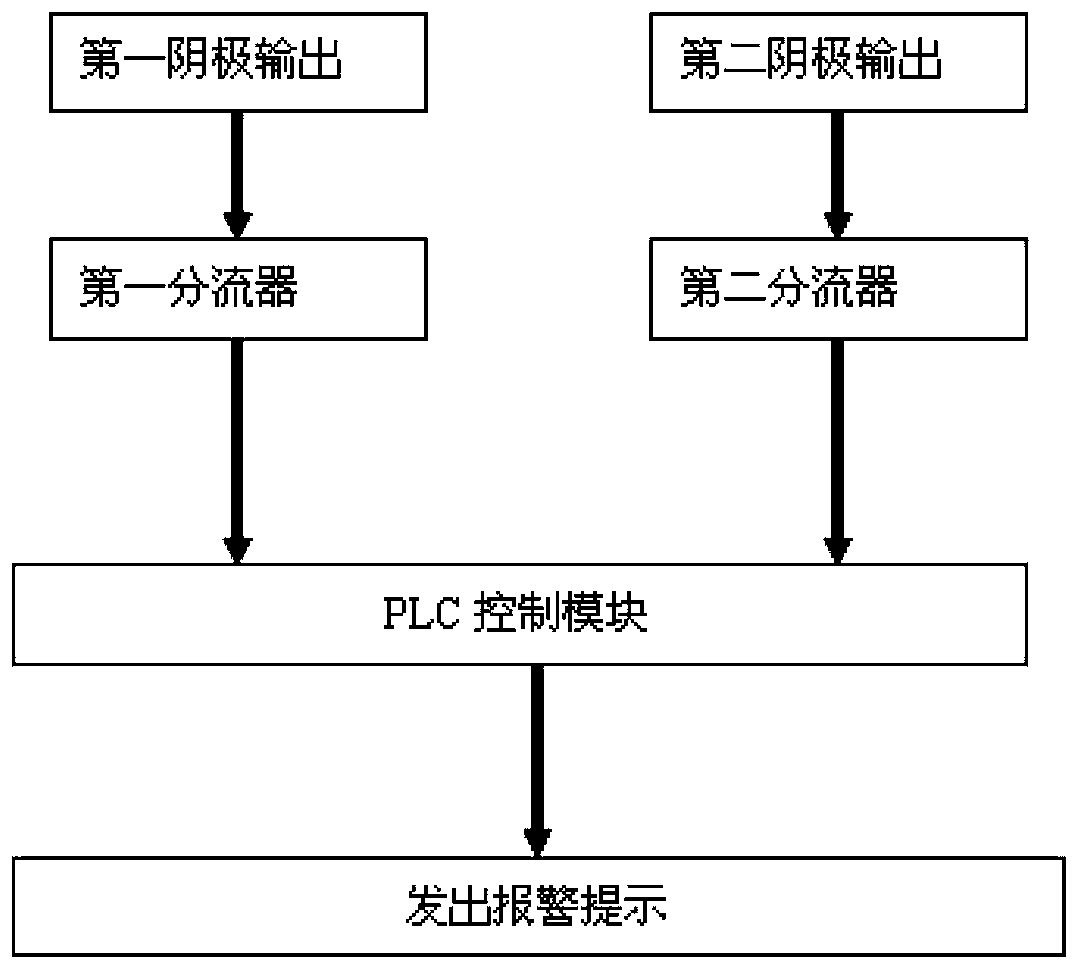

[0020] In this implementation, the power supply is provided with two cathode outputs, and each of the two cathode outputs has a conductive head to transmit current to the workpiece to be plated. Since the power supply adopts constant current output mode, the sum of the output currents of the two conductive heads is the set output current of the power supply.

[0021] The set constant current output of the power supply is 20A, and the PLC control module records the current data once every 0.1 second.

[0022] The current output on the first conductive head recorded for the first time is I 1 , the current output on the second conductive head is I 1 ′, the current difference between the two conductive heads is ⊿I 1 ; The current output on the first conductive head of the nth record by analogy is I n , the current output on the second conductive head is I n ′, the current difference between the two conductive heads is ⊿I n .

[0023] The inventor found through simulation tes...

Embodiment 2

[0026] In Example 2, the power supply has only one cathode output. In this case, the PLC control module records one current data each time, and then calculates the current difference between the two consecutive records. If the number of times that the current difference is smaller than the preset value reaches a predetermined number of times within the set time period, an alarm prompting that the drum stops rotating will be issued.

[0027] Same as Embodiment 1, the alarm prompt of power-off is also determined by detecting whether the current exceeds a preset fluctuation range. If the PLC control module detects that the number of times that the current exceeds the fluctuation range reaches a predetermined number of times within the set time period, an alarm prompt for power-off will be issued.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap