Method for automatically evaluating errors of three-dimensional geometrical shapes

A technology for three-dimensional geometry and error evaluation, applied in special data processing applications, measuring devices, instruments, etc., can solve the problems that cannot fully reflect the true shape information of the measured workpiece, and the measurement and evaluation process is cumbersome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

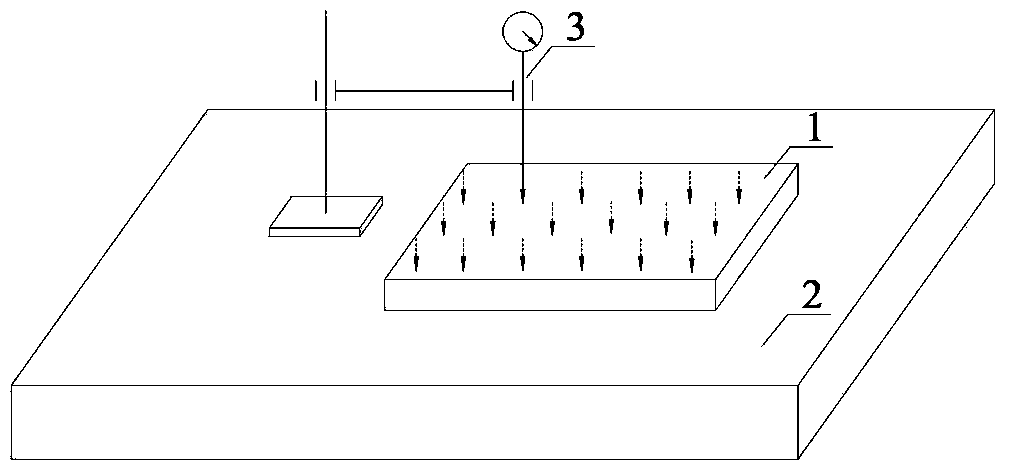

Embodiment 1

[0035] 1) Obtain the coordinate values p of n sampling points of the measurement point set P i =(x i ,y i ,z i ), i=1,2,...,n, the surface normal vector n corresponding to the n points is calculated by the discrete point k neighborhood differential plane fitting method i =(x ni ,y ni ,z ni ), i=1,2,...,n;

[0036] 2) Use the coordinate value p of the measurement point set i and its corresponding normal vector coordinate value n i , calculate the eigenvalues and eigenvectors of the discriminant matrix N, and get k=3, α 1 =0,ω 2,3 =0,ω 1 ≠0, according to Table 1, it is determined that the surface category corresponding to the point set is plane C P , and the unit normal vector T of the plane where the measuring point set is located P = ω 1 =(a P ,b P ,c P ), where a P , b P 、c Pis the coordinate value of the unit normal vector;

[0037] 3) Determine the error evaluation mathematical model according to the identification and judgment results

[0038] ...

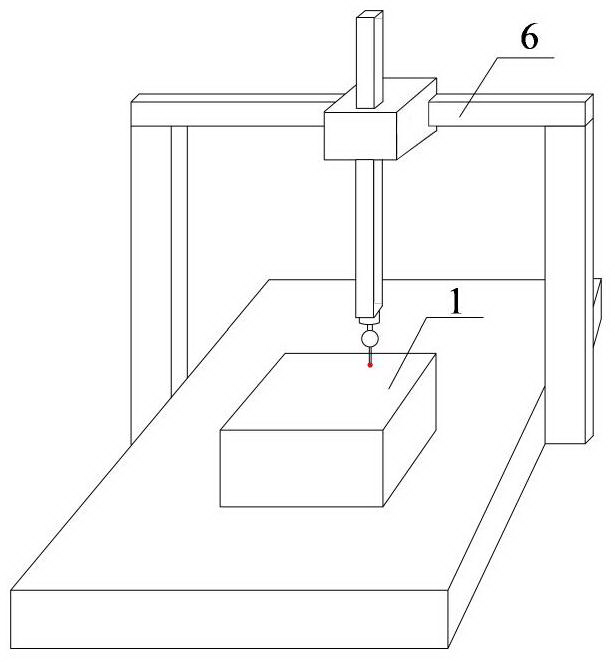

Embodiment 2

[0045] 1) Obtain the coordinate values p of n sampling points of the measurement point set P i =(x i ,y i ,z i ), i=1,2,...,n, the surface normal vector n corresponding to the n points is calculated by the discrete point k neighborhood differential plane fitting method i =(x ni ,y ni ,z ni ), i=1,2,...,n;

[0046] 2) Use the coordinate value p of the measurement point set i and its corresponding normal vector coordinate value n i , calculate the eigenvalues and eigenvectors of the discriminant matrix N, and get k=3, α 1,2,3 =0,ω 1,2,3 ≠0, according to Table 1, it is determined that the surface category corresponding to the point set is spherical C S ;

[0047] 3) Determine the error evaluation mathematical model according to the identification and judgment results

[0048] min t , x max e ( p i ...

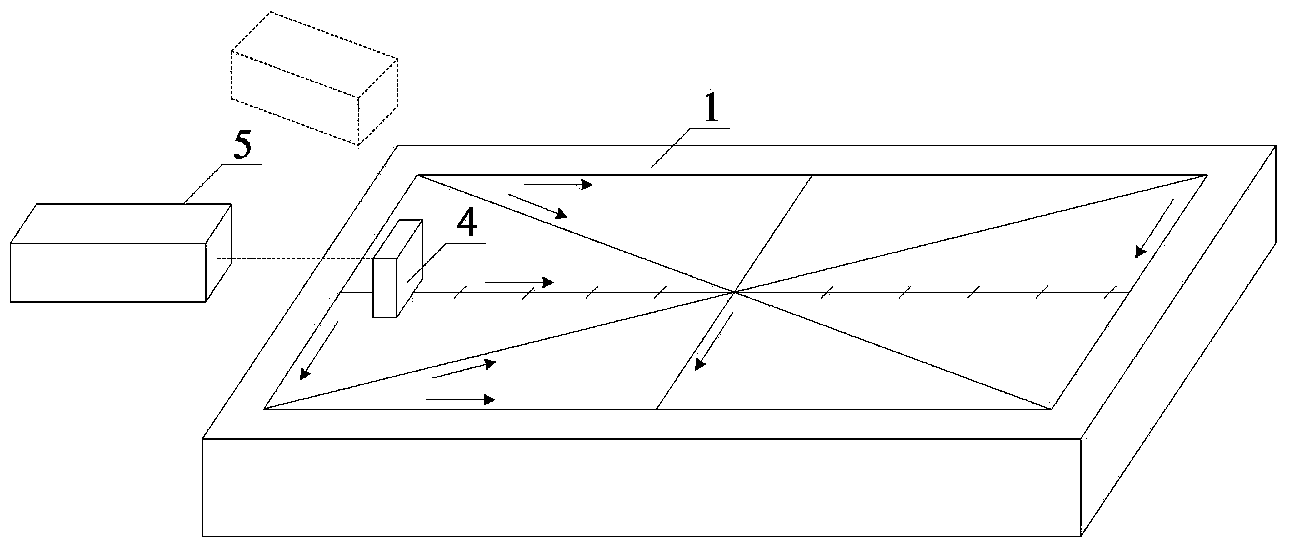

Embodiment 3

[0058] 1) Obtain the coordinate values p of n sampling points of the measurement point set P i =(x i ,y i ,z i ), i=1,2,...,n, the surface normal vector n corresponding to the n points is calculated by the discrete point k neighborhood differential plane fitting method i =(x ni ,y ni ,z ni ), i=1,2,...,n;

[0059] 2) Use the coordinate value p of the measurement point set i and its corresponding normal vector coordinate value n i , calculate the eigenvalues and eigenvectors of the discriminant matrix N, and get k=2, α 1 = ω 2 =0,ω 1 = α 2 , according to Table 1, it is determined that the surface category corresponding to the point set is a cylindrical surface C C , and the axis direction vector T of the cylindrical surface C = ω 1 = α 2 =(a C ,b C ,c C ), where a C , b C 、c C is the coordinate value of the unit direction vector;

[0060] 3) Determine the error evaluation mathematical model according to the identification and judgment results

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com