Treatment method for preventing corrosion caused by electrolyte leakage during inverted use of storage battery for UPS (uninterrupted power supply)

A processing method and storage battery technology, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems of poor applicability, and achieve the effect of low cost, flexible and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

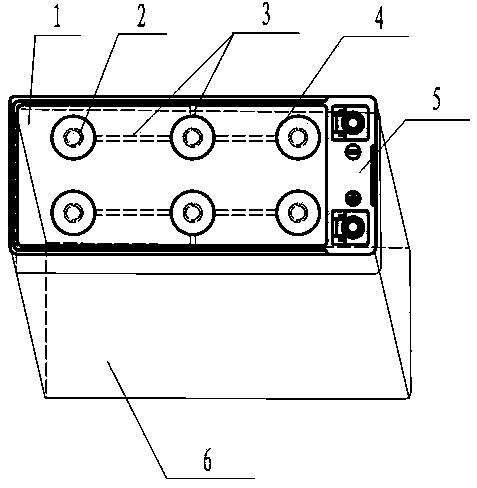

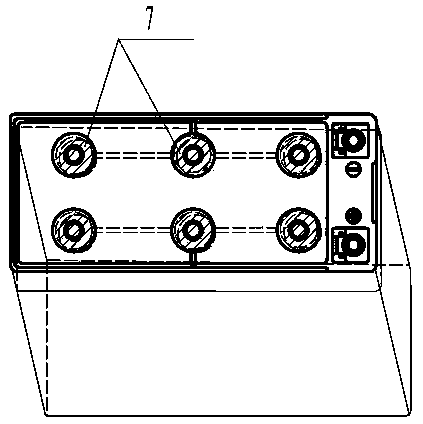

[0012] exist figure 2 In the example shown, the suction gasket (7) is fitted over the figure 1 On the liquid injection hole (2) covered with the rubber cap, after confirming that the liquid injection hole (2) covered with the rubber cap on the battery cover (5) is completely covered, seal it with the cover sheet (4).

[0013] When the battery is placed upside down and used, a small part of the electrolyte in the battery tank (6) will drip under the action of gravity and flow to the vicinity of the liquid injection hole (2) covered with a rubber cap. After the liquid injection hole (2) of the rubber cap overflows, the electrolyte is immediately absorbed by the liquid absorbing gasket (7), so as to ensure that the electrolyte will not overflow to the upper surface of the battery cover (1) and cause corrosion of the appearance or equipment. The electrolyte absorbed in the liquid absorbing gasket (7) gradually volatilizes water in the following time and is discharged from the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com