A Varying Temperature Roasting Method for Wuyi Mountain Dahongpao

A baking method and Dahongpao technology are applied in the field of temperature-changing Dahongpao baking in Wuyi Mountain, which can solve the problems of Dahongpao's weak and unsustainable taste, burnt smell, serious bitterness and astringency, etc., so as to improve the drinking value and improve the aroma and aroma of tea leaves. rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

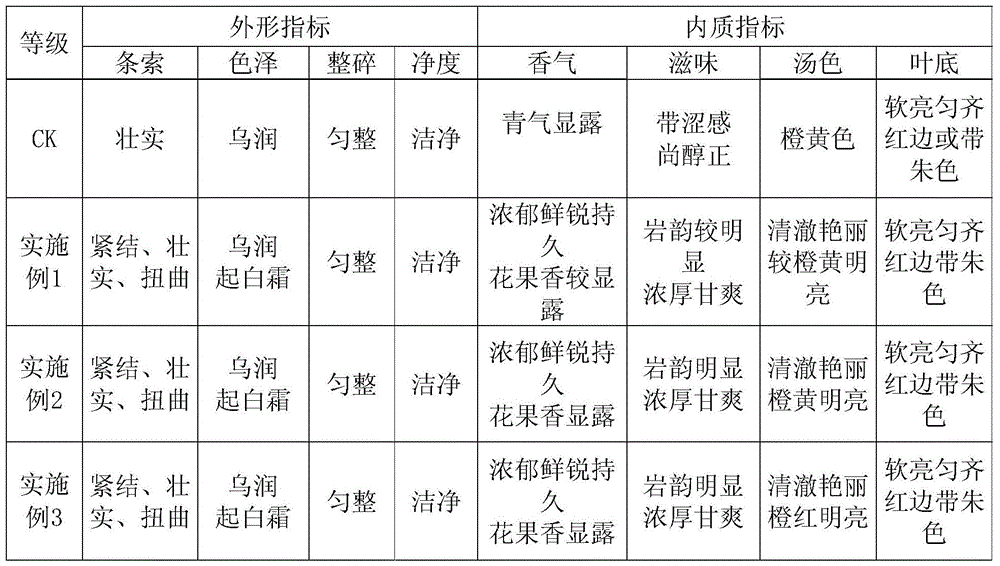

Examples

Embodiment 1

[0027] Select 10KG spring Wuyi Dahongpao tea and spread it evenly on the baking board.

[0028] Impurity removal stage: set the temperature at 120°C, turn on the machine and preheat for 15 minutes to reach the temperature, then push the tea leaves into the oven, adjust the pointer of the baking equipment to keep the temperature of the tea leaves at 120°C for 30 minutes. Turn the tea leaves once during this period.

[0029] Heating stage: set the temperature at 155°C, raise the temperature to 155°C at a rate of 1.4°C / min, and keep it for 30 minutes. During this period, turn the tea leaves once to ensure that the tea leaves are heated evenly.

[0030] Constant temperature stage: set the temperature at 150°C, cool down to 150°C at a rate of 0.5°C / min, and last for 50 minutes. During this period, the tea leaves are turned three times to ensure that the tea leaves are heated evenly.

[0031] Setting stage: set the temperature to 165°C, and raise the temperature to 165°C at a rat...

Embodiment 2

[0034] Select 10KG spring Wuyi Dahongpao tea and spread it evenly on the baking board.

[0035] Impurity removal stage: set the temperature at 125°C, turn on the machine and preheat for 20 minutes to reach the temperature, then push the tea into the oven, adjust the pointer of the baking equipment to keep the tea temperature at 125°C for 35 minutes. Turn the tea leaves once during this period.

[0036] Heating phase: set the temperature to 160°C, raise the temperature to 160°C at a rate of 1.25°C / min, and keep it for 35 minutes. During this period, turn the tea leaves once to ensure that the tea leaves are heated evenly.

[0037] Constant temperature stage: set the temperature at 155°C, lower the temperature to 155°C at a rate of 0.5°C / min, and last for 55 minutes. During this period, the tea leaves are turned three times to ensure that the tea leaves are heated evenly.

[0038] Setting stage: set the temperature to 170°C, and raise the temperature to 170°C at a rate of 0.8...

Embodiment 3

[0041] Select 10KG spring Wuyi Dahongpao tea and spread it evenly on the baking board.

[0042] Impurity removal stage: set the temperature at 130°C, turn on the machine and preheat for 25 minutes to reach the temperature, then push the tea leaves into the oven, adjust the pointer of the baking equipment to keep the temperature of the tea leaves at 130°C for 40 minutes. Turn the tea leaves once during this period.

[0043] Heating stage: set the temperature at 165°C, raise the temperature to 165°C at a rate of 1.17°C / min, and keep it for 40 minutes. During this period, turn the tea leaves once to ensure that the tea leaves are heated evenly.

[0044] Constant temperature stage: set the temperature at 160°C, cool down to 160°C at a rate of 0.38°C / min, and last for 60 minutes. During this period, the tea leaves are turned three times to ensure that the tea leaves are heated evenly.

[0045] Styling stage: set the temperature at 175°C and raise the temperature to 175°C at a ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com