Composite internal separating and grinding device of pipe grinder

A tube mill and powder selection technology, which is applied in solid separation, sieve, grille and other directions, can solve the problems of inconvenient installation and maintenance, low material passing speed, and large space in the mill, and achieves remarkable material passing effect. Simple structure design, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

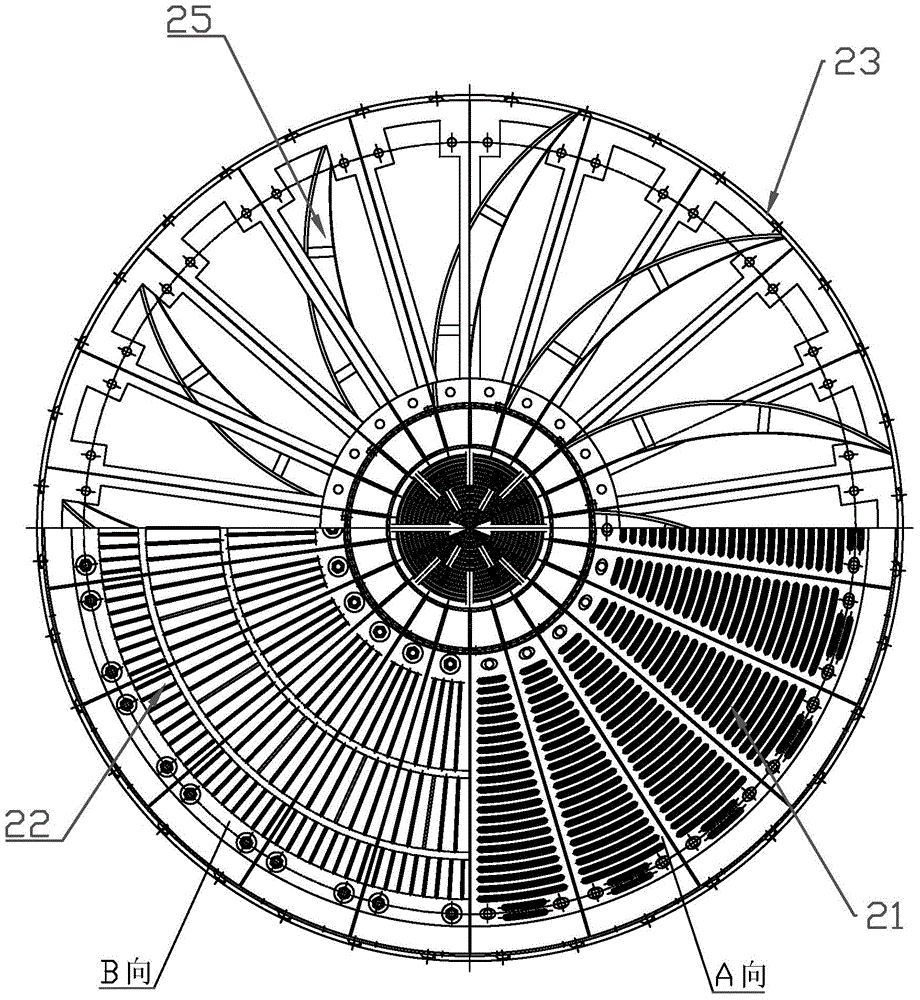

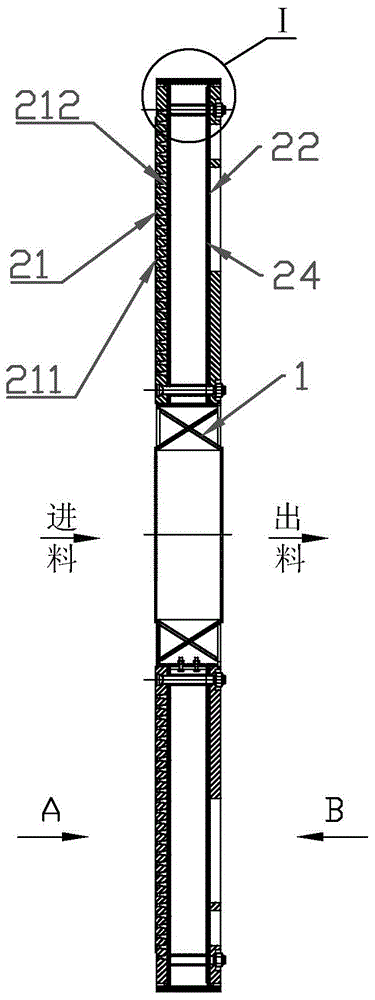

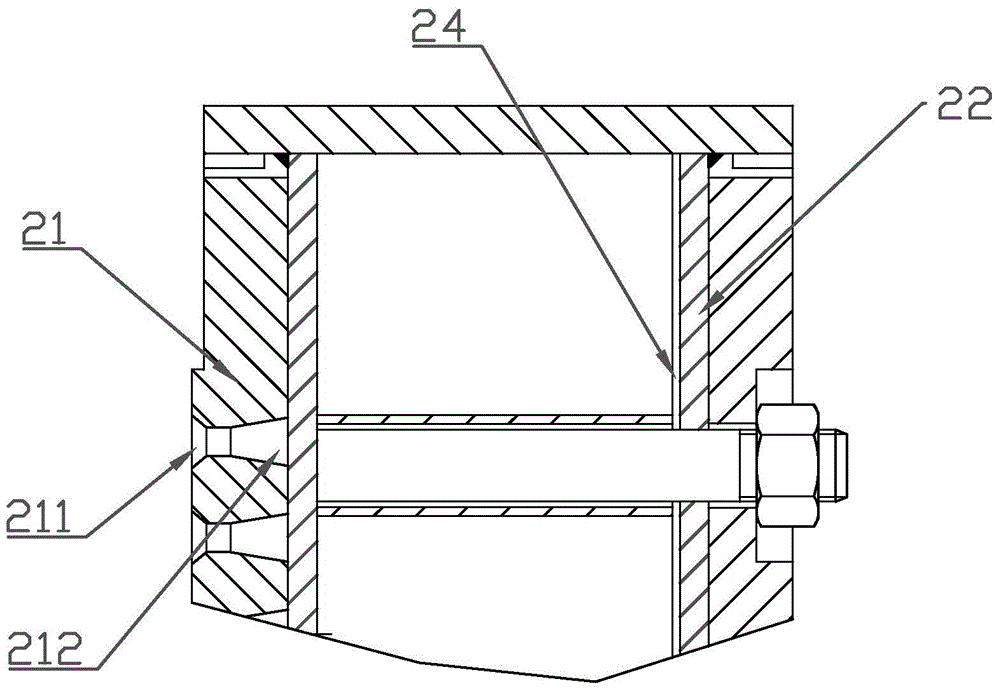

[0025] Such as Figure 1-11 As shown, the present invention is a composite internal powder selection device of a tube mill, which is installed inside the barrel of the tube mill when in use. The compound internal powder selection device of the tube mill includes a circular bidirectional feeder cone 1, the edge of the bidirectional feeder cone 1 is connected with several internal powder compartment grate plates in sequence along its circumferential direction. The grate plate of the powder compartment includes a front grate plate 21, a rear grate plate 22, a grate plate support 23, a flat sieve plate 24 and a lifting plate 25. The front grate plate 21 and the rear grate plate 22 are fixed on the grate plate by bolts. on the bracket 23.

[0026] A cavity 3 is formed between the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com