Tool marking method

A tool and marking technology, applied in the field of tool identification, can solve the problems of discarded packaging containers, unclear tool-related information, damaged labels and stickers, etc., and achieve the effect of facilitating management and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

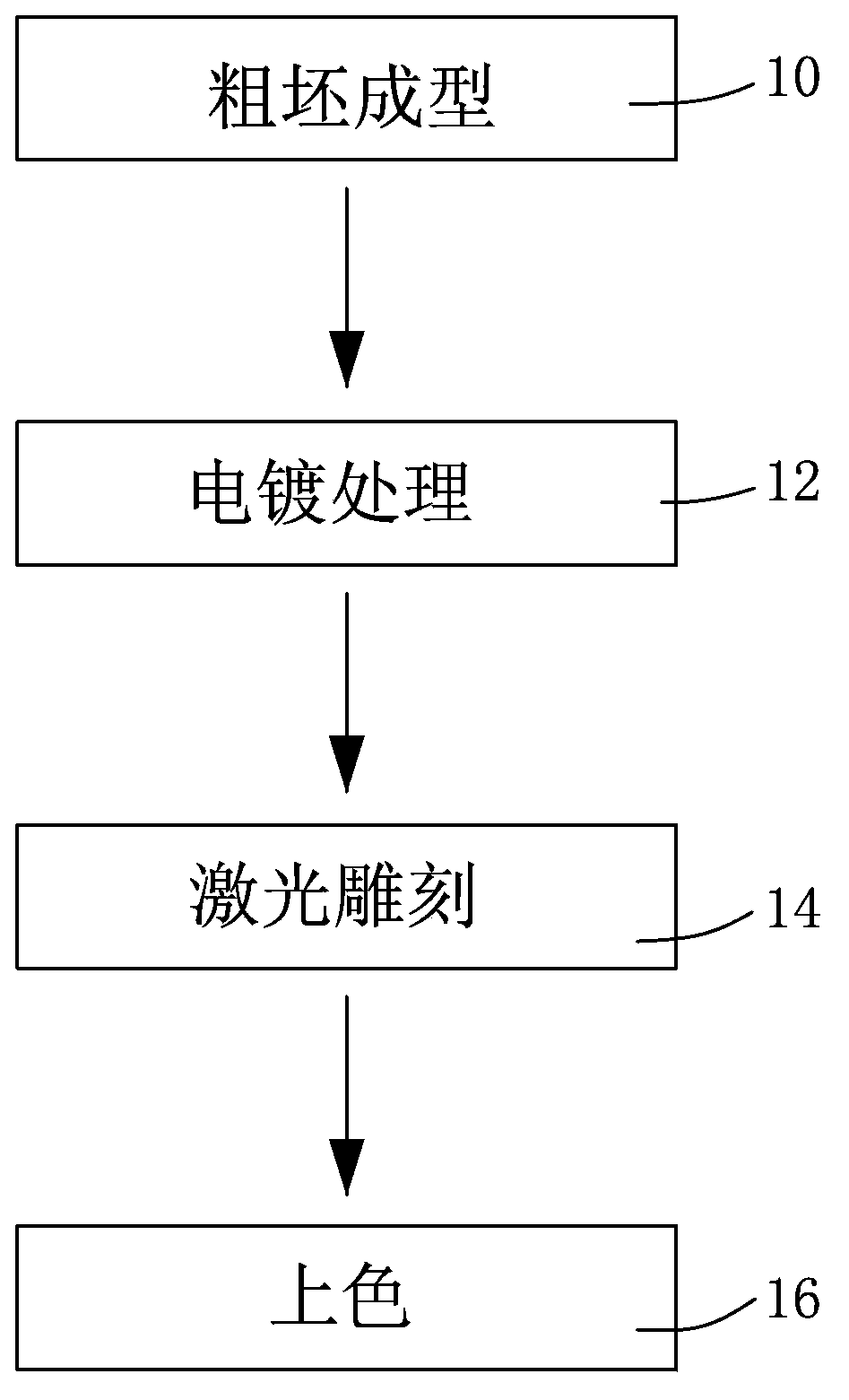

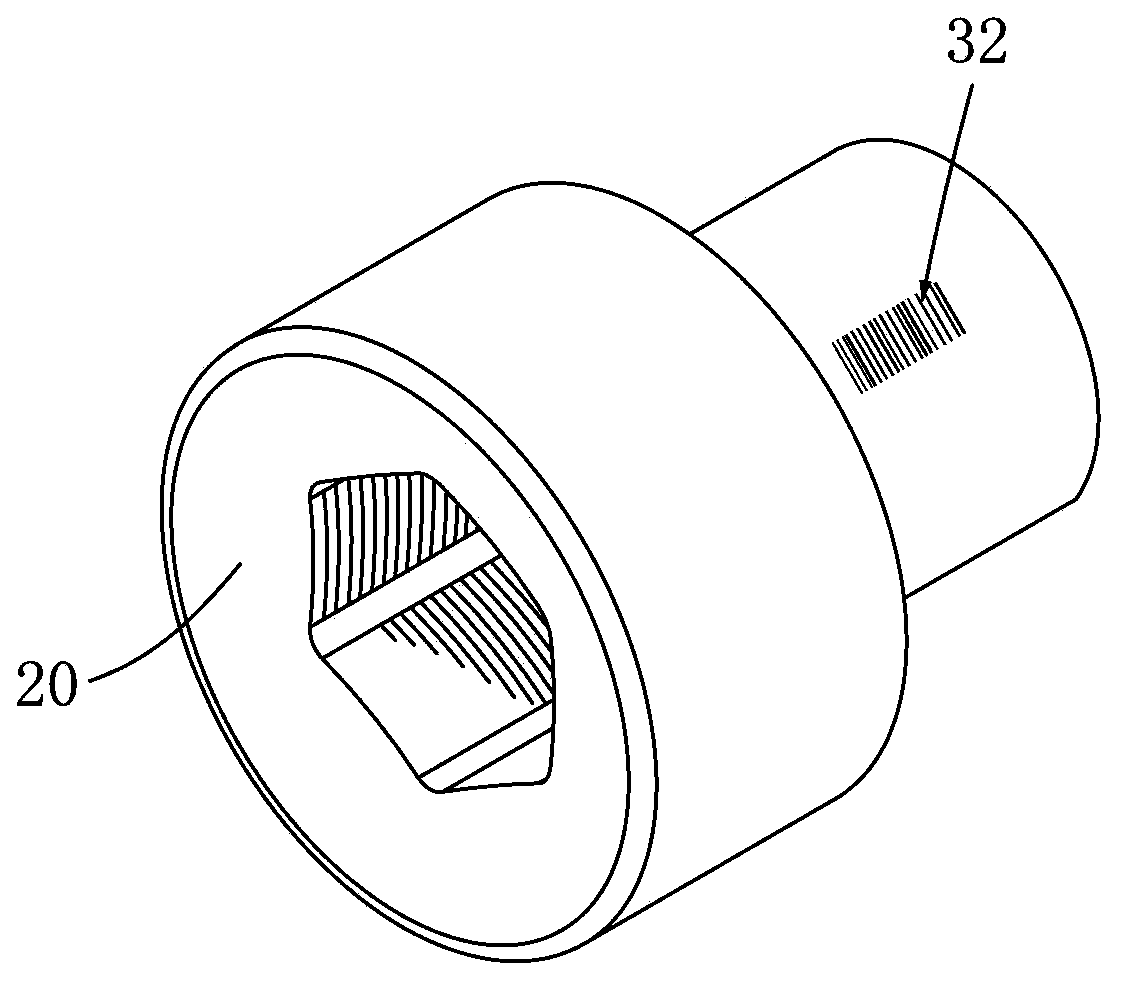

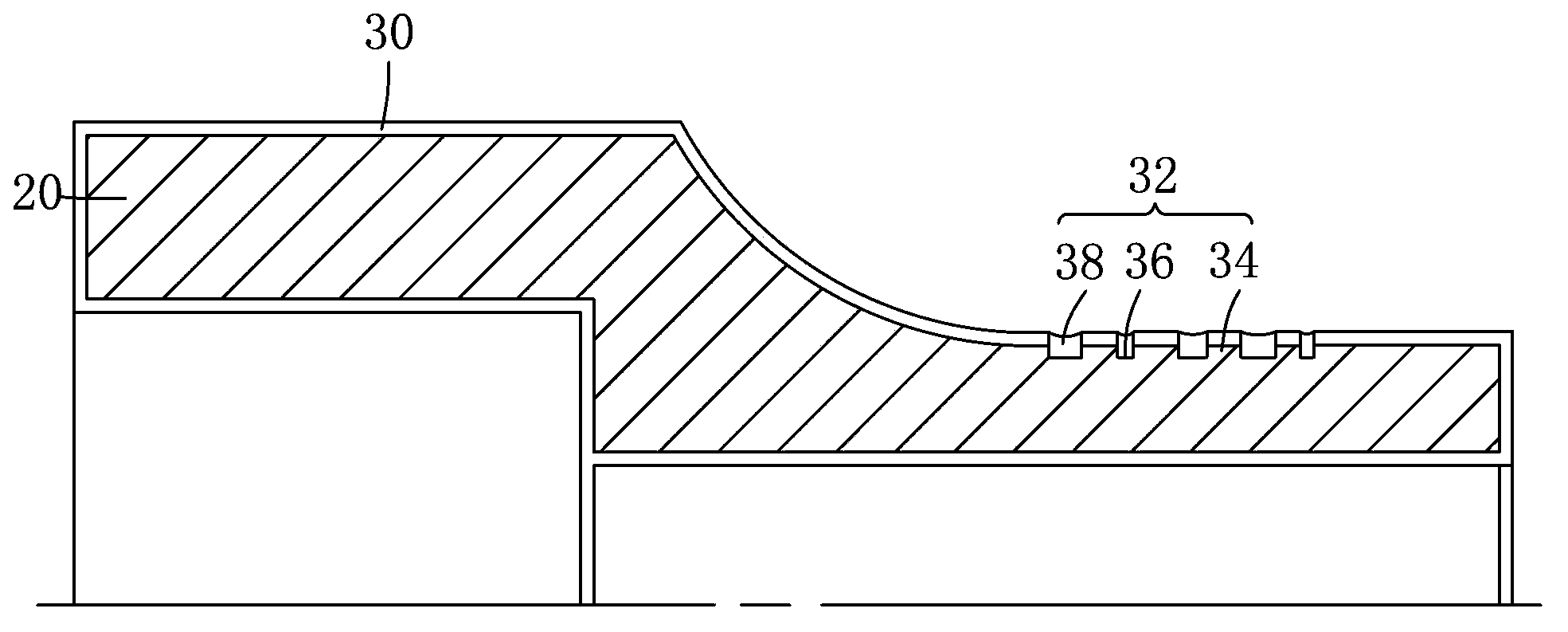

[0031] See figure 1 , To clarify the tool making process, starting from a rough embryo forming 10, going through the steps of electroplating 12 and laser engraving 14, until coloring 16, to complete the tool with barcode. In order to help readers understand the production process, the next interview will take the sleeve as an example. figure 2 , image 3 Explain in detail.

[0032] In the 10 steps of forming the rough embryo, the metal material uses high-pressure molding, cutting or forging equipment and machines to produce the rough embryo 20. The rough embryo 20 has the outline of the sleeve and includes a latch. The latch has a quadrilateral recessed structure. The concavity and convexity fit on the protruding part of the wrench; the set part and the set part are mostly hexagonal recessed structures, which can accommodate screwdriver heads, bolts or nuts of the same size.

[0033] In the 12 steps of the electroplating treatment, a layer of other metal is usually spread on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com