Nitrogen removal system and treatment process of urban sewage with low carbon-to-nitrogen ratio based on anaerobic ammonium oxidation

A technology of anaerobic ammonium oxidation and urban sewage, applied in the field of sewage biological treatment, can solve the problems of large excess sludge output, high energy consumption and material consumption in operation, and low resource utilization rate, and achieve low excess sludge output and low energy consumption in operation The effect of low material consumption and short start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

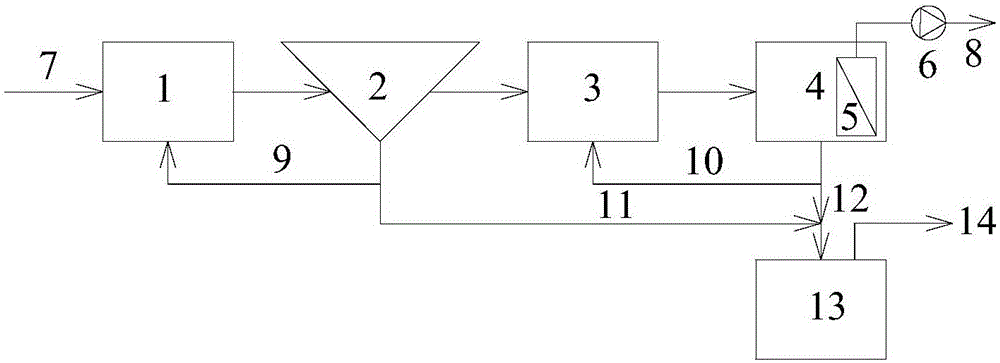

[0033] Embodiment one: a kind of low carbon nitrogen ratio urban sewage denitrification treatment process based on anaerobic ammonium oxidation, comprises the following steps:

[0034] a. After pretreatment (thick and fine grid, grit chamber), the urban sewage enters the aeration tank 1 through the urban sewage inlet pipe 7, and in the aeration tank 1, the return sludge from the sedimentation tank 2 is used to treat the urban sewage Most of the organic matter undergoes biosorption, the treatment time is 20 minutes, and the sludge reflux ratio is 20%; the mud-water mixture discharged from the aeration tank 1 enters the sedimentation tank 2 for mud-water separation, and the treatment time is 1.5 hours; the MLSS of the aeration tank 1 ( Mixed liquor sludge concentration) is 1.5g / L, DO (dissolved oxygen) concentration is 0.2mg / L;

[0035] b. The urban sewage discharged from the sedimentation tank 2 is mixed with the reflux liquid of the nitrosation tank 4 and enters the anammox ta...

Embodiment 2

[0039] Embodiment two: a kind of low carbon nitrogen ratio urban sewage denitrification treatment process based on anaerobic ammonium oxidation, comprises the following steps:

[0040] a. After pretreatment (thick and fine grid, grit chamber), the urban sewage enters the aeration tank 1 through the urban sewage inlet pipe 7, and in the aeration tank 1, the return sludge from the sedimentation tank 2 is used to treat the urban sewage Most of the organic matter undergoes biosorption, the treatment time is 40 minutes, and the sludge reflux ratio is 50%; the mud-water mixture discharged from the aeration tank 1 enters the sedimentation tank 2 for mud-water separation, and the treatment time is 2 hours; the MLSS of the aeration tank 1 ( Mixed liquor sludge concentration) is 2.0g / L, DO (dissolved oxygen) concentration is 0.4mg / L;

[0041] b. The urban sewage discharged from the sedimentation tank 2 is mixed with the reflux liquid of the nitrosation tank 4 and enters the anammox tank...

Embodiment 3

[0045] Embodiment three: a kind of low carbon nitrogen ratio urban sewage denitrification treatment process based on anaerobic ammonium oxidation, comprises the following steps:

[0046] a. After pretreatment (thick and fine grid, grit chamber), the urban sewage enters the aeration tank 1 through the urban sewage inlet pipe 7, and in the aeration tank 1, the return sludge from the sedimentation tank 2 is used to treat the urban sewage Most of the organic matter undergoes biosorption, the treatment time is 30min, and the sludge reflux ratio is 30%; the mud-water mixture discharged from the aeration tank 1 enters the sedimentation tank 2 for mud-water separation, and the treatment time is 2 hours; the MLSS of the aeration tank 1 ( Mixed liquor sludge concentration) is 2g / L, DO (dissolved oxygen) concentration is 0.3mg / L;

[0047] b. The urban sewage discharged from the sedimentation tank 2 is mixed with the reflux liquid of the nitrosation tank 4 and enters the anammox tank 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com